2016 Honda Civic designed to be ‘epic,’ safe through structural steel designs

By onEducation | Repair Operations | Technology

Innovative “soft zone” areas within ultra-high-strength steel components on the 2016 Honda Civic are just one of the special structural elements managing crash energy, engineers explained earlier this year.

This design apparently worked, netting the popular car top safety marks from both the IIHS and NHTSA and indicating owners will fare well in a crash. But now comes the real world, and it’s up to auto body shops to ensure the hundreds of thousands of next-generation Civics maintain these ratings should the cars get in a second collision.

Without everyone working on the car looking up and following Honda repair procedures every time, a shop risks screwing up the way the vehicle manages crash energy — putting their customer at risk of injury or worse.

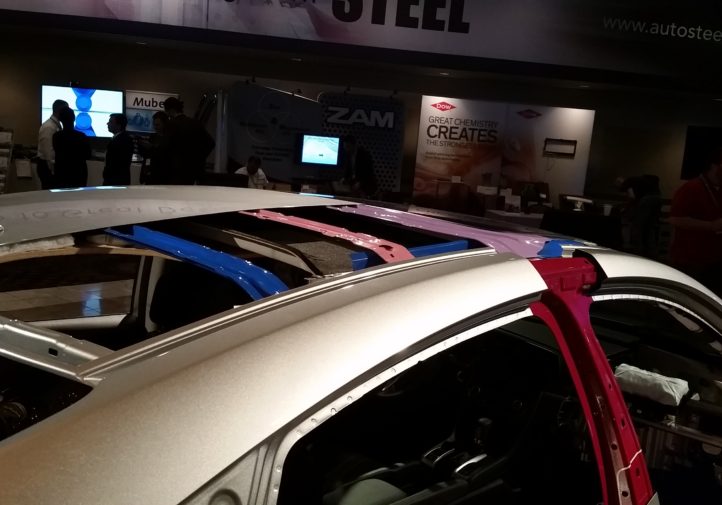

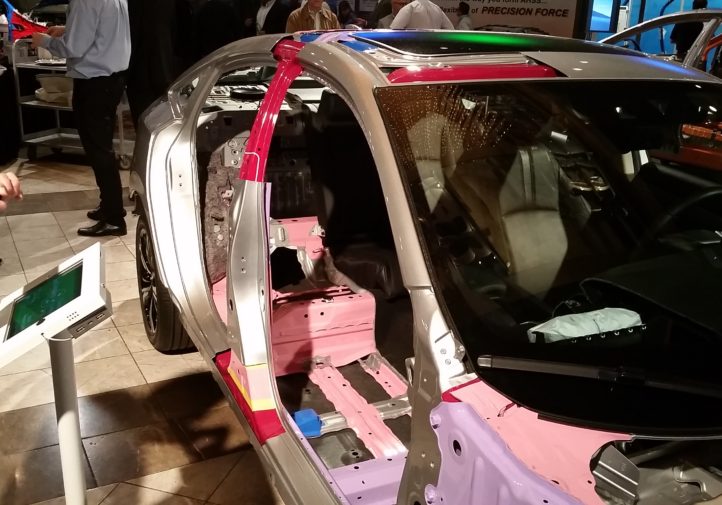

Let’s take a look at some of these elements using 2016 Civic body designer Shawn Crichley and upper body designer TJ Palesano’s presentation at Great Designs in Steel — and while we’re fortunate enough to have the car color-coded. Besides their slides and a truncated version of the graphics in the exhibit hall, Honda produced a slick Civic cutaway model which can be seen in the gallery below.

Don’t miss any opportunity to check out the last of these at trade shows should the cutaway make an appearance. For now, get a taste through the presentation link and our gallery below.

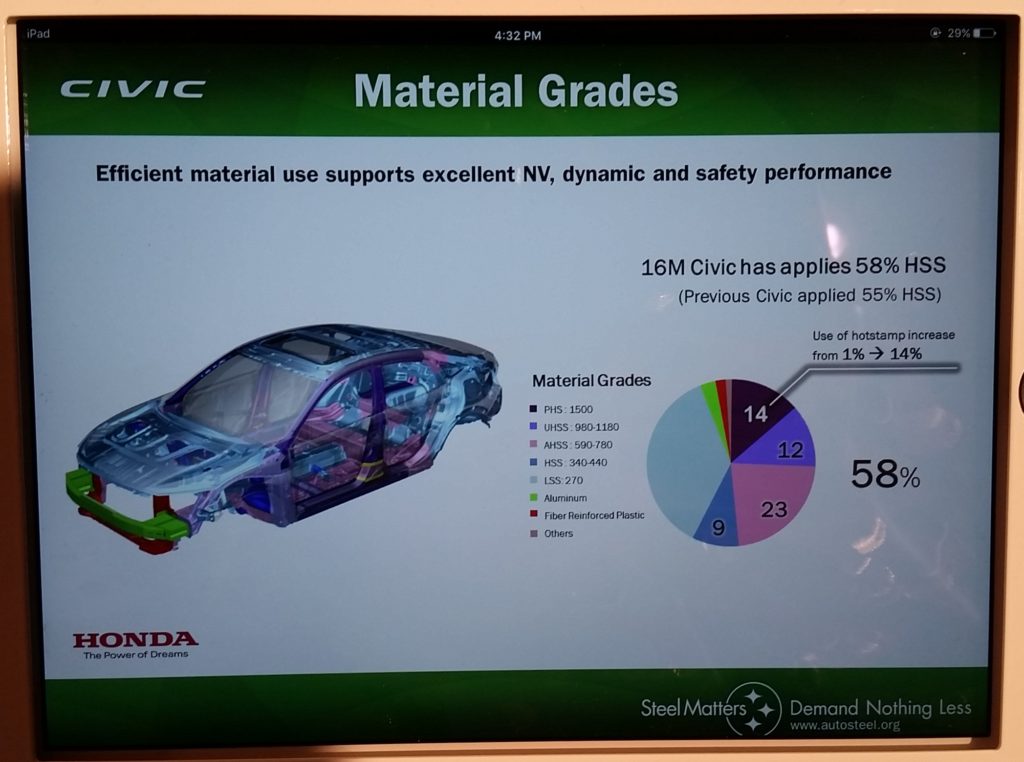

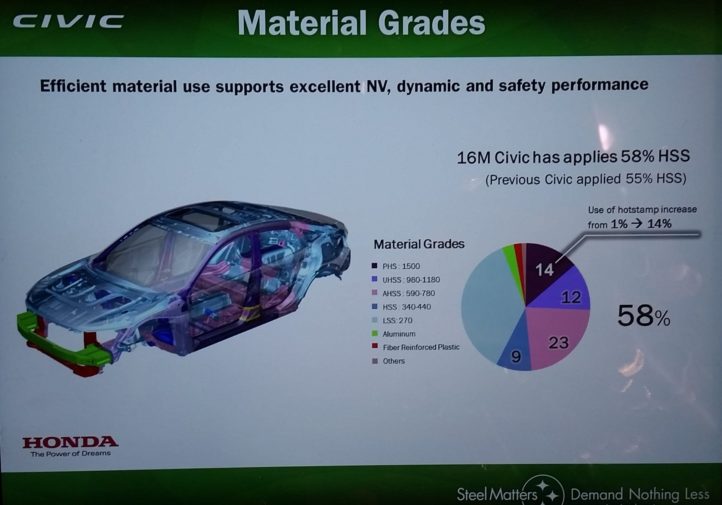

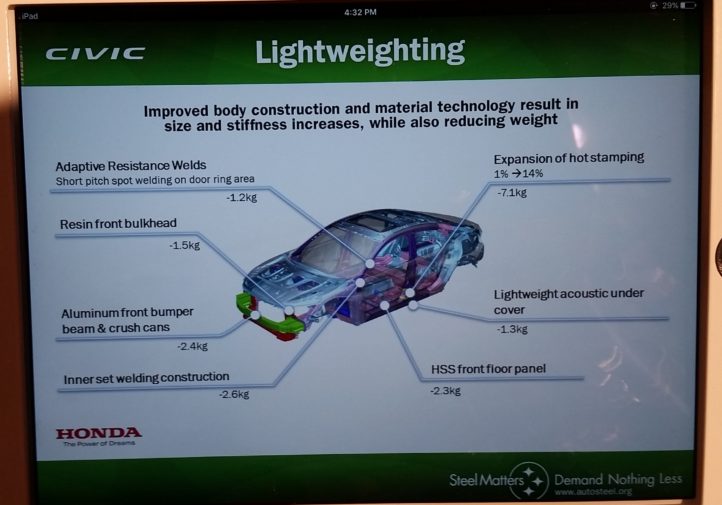

Note that at least 26 percent of the car (light and dark purple) is ultra-high-strength steel of 980 megapascals or more — indicating there’s often little you can do besides replace it entirely. Within that UHSS is a subset of press-hardened/hot-stamped 1,500 MPa steel that has grown from 1 percent to 14 percent.

Another 23 percent of the car lies in the 590-780 MPa range of advanced high-strength steel, which can require special repair considerations as well.

You certainly won’t see a body so conveniently color-coded during a repair, so keep those Honda repair procedures handy so you know what you’re working on and what you should do with it.

Safety, other body design

Crichley said the overall design goal for the 2016 Civic was an “epic Civic” which would be the best C-segment vehicle in the world. The OEM sought European-type dynamics with a larger North American size. (Also, the Chinese market demanded the ability to fit three full-size pieces of luggage in the car.)

In fact, Crichley noted that the “low and wide” design almost got the OEM to a D-segment.

Handling elements include hydraulic bushings on the lower A-pillar, and the LX and EX trims bumped up power and torque over the prior-generation 2015 Civic, according to Crichley. Honda also pursued gas mileage, trying to exceed its fellow mpg leaders.

“We’ve tried to push out of that segment,” he said.

The ride improves further in terms of NVH dampening through the use of fiber undercovers “typically reserved for higher-class vehicles,” Palesano said.

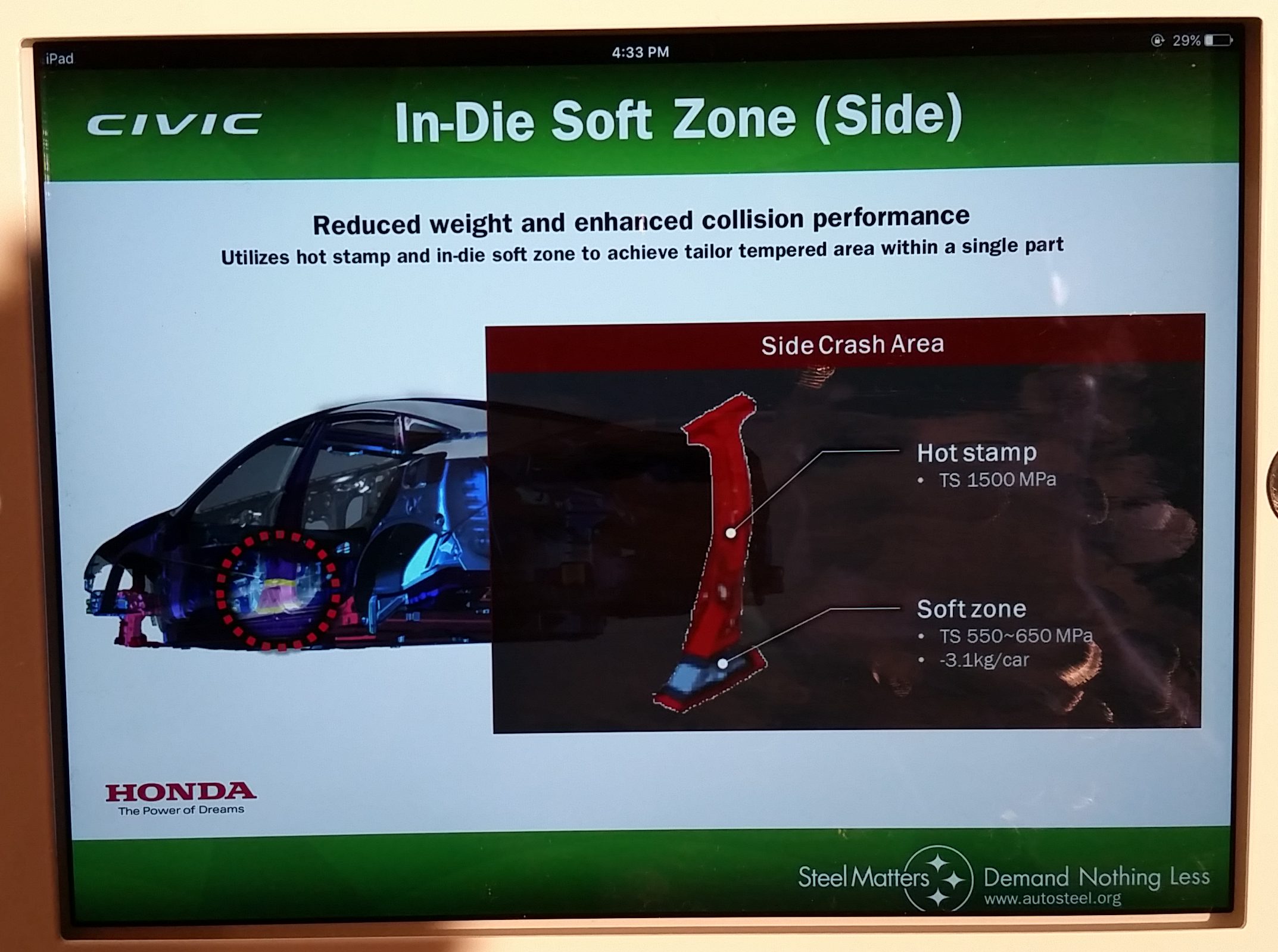

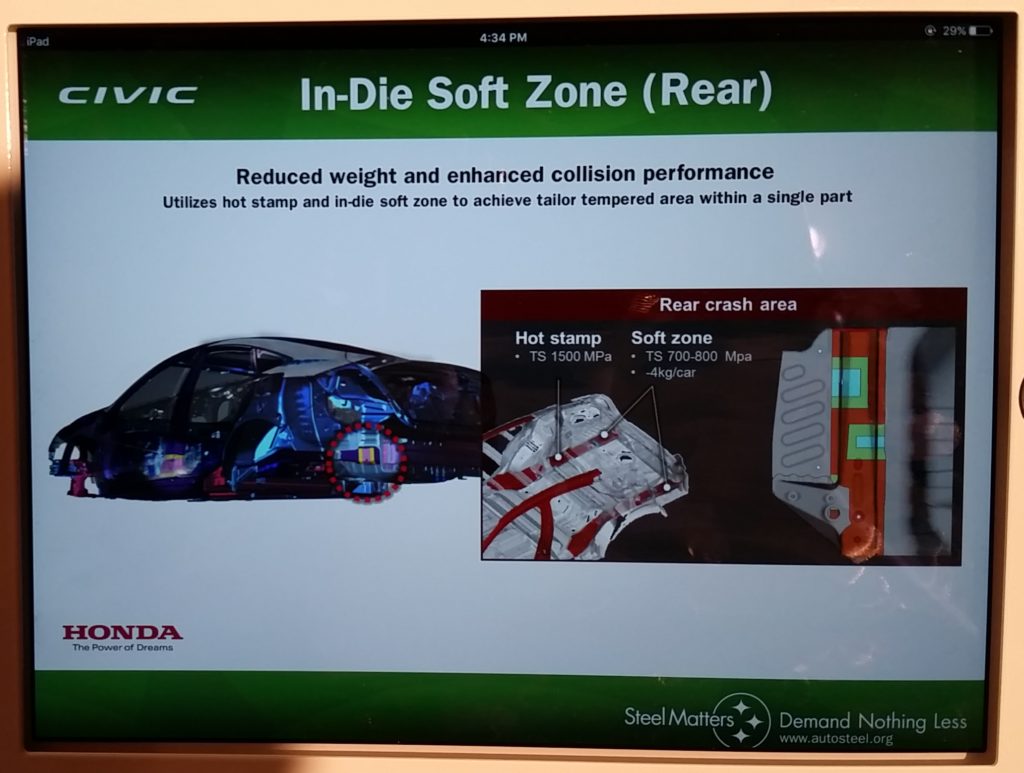

The other big payoff is safety. Honda used Gestamp soft zone technology to create tailored, tempered areas in 1,500 MPa steel, Crichley said. This allows the car to absorb some energy by deforming near the bottom of the B-pillar and three areas in the rear frame rails — but not too much.

It’s the bend, but don’t break school of thought, and Crichley said the soft zones deliver a “consistent crash result in the rear” and keep the B-pillar from overly intruding into the passenger cage. The rear frame rails, however, remain strong enough (1,500 MPa steel) to protect the fuel tank.

This clever trick makes those components even more crucial to correctly handle during the repair process or risk throwing off the kind of controlled destruction Honda intends.

Honda didn’t forget about the front of the car either, including how the Civic’s shorter overhang would make a 5-star NHTSA crash rating more difficult, according to Crichley.

He said the bumper beams and crush cans — both made of aluminum — are stronger (and lighter) than on the previous-generation Civic.

Crichley said the car also has small brackets on the subframe, seen in the following video. These pull the subframe down and bend it strategically to absorb more frontal-collision energy.

The sill also used to split away on the older Civic during a tire impact, he said, but Honda addressed this with overlap welds to compress the structure. He said a higher-strength floor pan also helped keep the welds intact.

Finally, the front of the vehicle has a steel and resin composite bulkhead, which Crichley said also helps in the event of a collision. Honda has warned that the entire bulkhead must be replaced in the event of damage.

See more details in Honda’s Great Designs in Steel presentation slides, its 2016 Civic Body Repair News overview and — of course — the actual repair procedures.

More information:

“New Global Model Introduction: The All-New 2016 Honda Civic”

Honda at Great Designs in Steel, May 11, 2016

Images:

A cutaway of the 2016 Honda Civic at Great Designs in Steel demonstrates the various steels and aluminum on the vehicle. (John Huetter/Repairer Driven News)

This Honda slide from the 2016 Great Designs in Steel demonstrates elements of the 2016 Honda Civic. (John Huetter/Repairer Driven News)

The soft zones on the 2016 Honda Civic can be seen in this Honda slide from the 2016 Great Designs in Steel. (John Huetter/Repairer Driven News)