Georgia Tech last month announced in a university magazine researchers have created a scalable process of reclaiming nearly 100 percent of the carbon fiber in certain composites — which could cut the cost and grow the appeal of automotive carbon fiber.

Carbon fiber-reinforced polymer, like many automotive composites, features reinforcing structures within a hardening resin matrix. It’s the same principal as rebar in concrete.

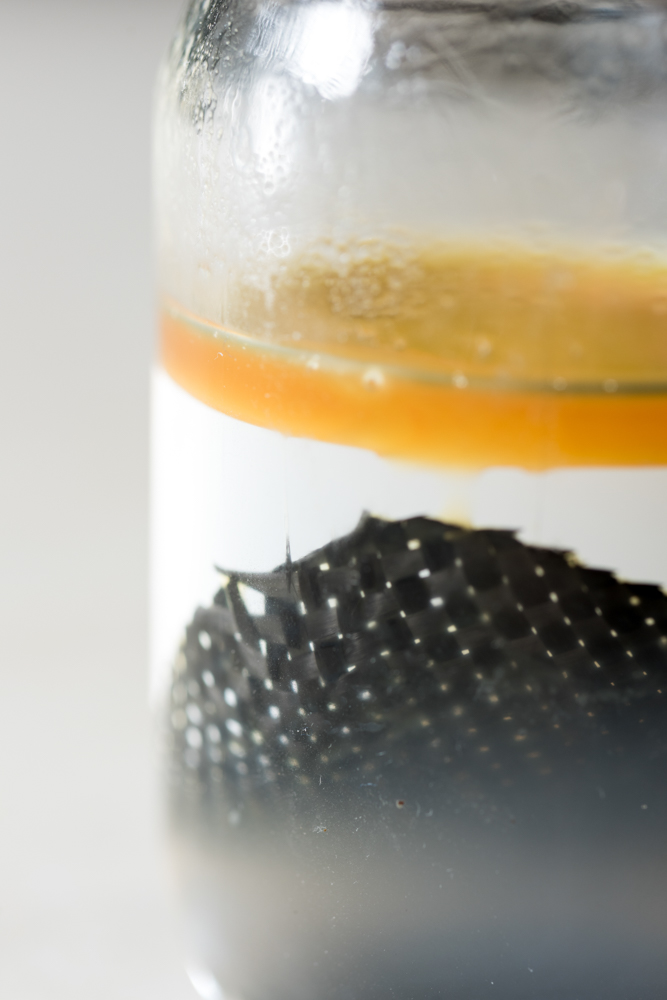

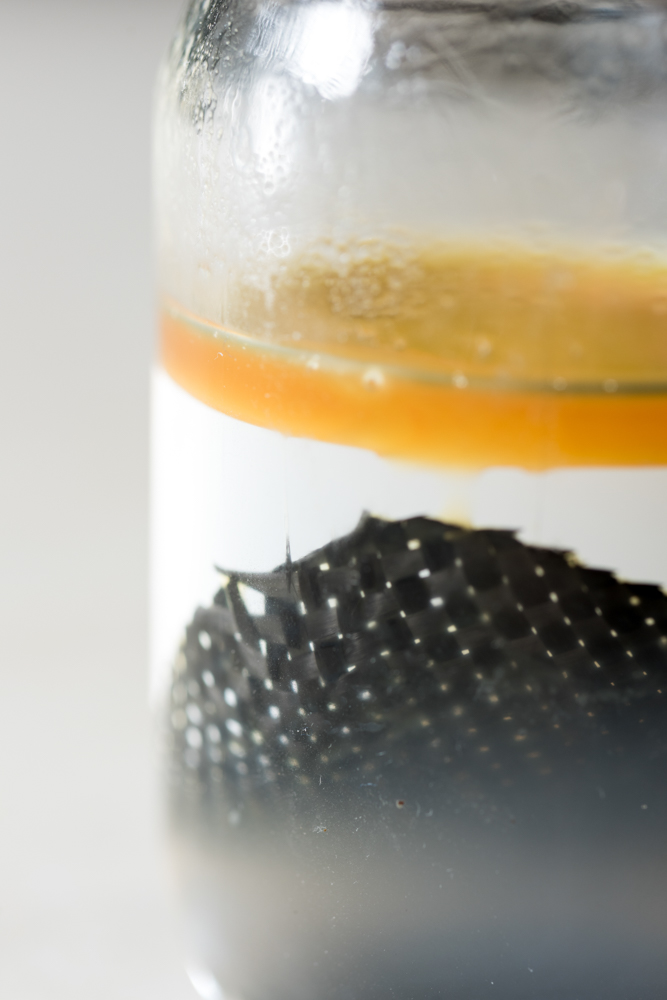

The Georgia Tech procedure works on the subset of carbon-fiber suspended in vitrimer epoxy. It dissolves the epoxy by soaking it in an alcohol solvent.

“Once dissolved, the carbon fibers and the epoxy can be separated and used in new applications,” Georgia Tech wrote July 21 in its magazine Research Horizons.

“This method we think could have a lot of immediate industrial applications, with lots economical and environment benefits,” former Georgia Tech postdoctoral researcher Kai Yu, now a professor at the University of Colorado-Denver, said to the magazine about his research, published earlier in July by Advanced Functional Materials.

“It’s very easy to operate, so there’s no limit to the size,” he said. “It can be easily scaled up.”

Its unclear what proportion of automotive carbon fiber — if any — uses vitrimer epoxy, which is different from what the piece calls “traditional carbon fiber.”

Learn more about carbon fiber at OEM Collision Repair Summit

Learn more about carbon fiber from General Motors body structures advanced composites engineering group manager Mark Voss during “Advanced Vehicle Materials, Construction and Repair Considerations” on Nov. 3 at SEMA. The second half of the segment features Dow Automotive aftermarket business marketing manager Frank V. Billotto, who’ll talk about how to join that carbon fiber and other mixed-material body designs with adhesives. The session is part of the 2016 OEM Collision Repair Technology Summit hosted by the Society of Collision Repair Specialists during the Repairer Driven Education Series Nov. 1-4. Register here.

“The polymer matrix (in traditional CFRP) is usually crosslinked, just like the rubber, and it can’t be simply melted; it’s very hard to strip away the polymer to reclaim the embedded carbon fibers, which are more valuable to recycle,” Georgia Tech professor Jerry Qi told Research Horizons.

“Vitrimers contain dynamic bonds that can alternate their structure without losing network integrity under certain conditions,” he said. “We let alcohol, which has small molecules, to participate in the network of alternating reactions, which effectively dissolved the vitrimer.”

Recycling is important not just from a cost perspective. Different materials industries competing for automotive body space tout their recyclability on environmental grounds — which on top of the feel-good benefits keep regulators happy.

The study was sponsored by not only the National Science Foundation, but also the Chinese National Natural Science Foundation and the Digital Manufacturing and Design Centre and A*Star Public Sector Fund in Singapore.

More information:

“New Carbon Fiber Recycling Process Could Help Firms Reduce Waste”

Georgia Tech Research Horizons, July 21, 2016

“Carbon Fiber Reinforced Thermoset Composite with Near 100% Recyclability”

Advanced Functional Materials, July 12, 2016

Images:

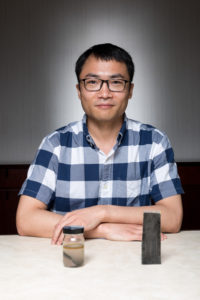

Kai Yu, a former postdoctoral researcher in The George W. Woodruff School of Mechanical Engineering at Georgia Tec, sits behind a piece of carbon fiber composite immersed in alcohol. (Rob Felt/Georgia Tech)

A piece of carbon fiber composite immersed in alcohol. (Rob Felt/Georgia Tech)

Share This:

Related