‘Significant changes’ announced for Honda, Acura welding, sectioning rules

By onAnnouncements | Education | Repair Operations | Technology

Responding to collision repairer input, Honda recently announced “significant changes” to its sectioning and welding guidelines for Hondas and Acuras.

Two of the biggest revisions appear to be Honda’s approval of certain welding on higher-strength steels under the right conditions.

Repairers can now MAG butt-weld any high-strength steels up to 780 megapascals — but be quick about it to avoid affecting the steel integrity, according to Honda. Previously, one could only MAG butt-weld up to 590 MPa.

“To minimize the heat-affected zone (HAZ), butt welds on 780 MPa steel must be done as quickly as possible, while maintaining adequate penetration,” Honda wrote in an August 2016 Body Repair News, which supersedes the earlier April 2014 version of the sectioning and welding guidelines. An Acura version can be found here.

Anything above 780 MPa is generally considered ultra-high-strength steel, and those metals still can’t be MAG butt-welded.

As for ultra-high-strength steels, Honda wrote that it would now allow MAG plug welding on 1,500 MPa steel, but only on certain designated areas — no exceptions.

“MAG plug welding is now allowed on 1,500 MPa (hot stamp) steel parts in select locations only as specified in the BRM (Body Repair Manual),” Honda wrote, doubling down on the emphasis. (Get repair manuals here.)

You don’t want to deviate from Honda’s instructions, the OEM warned, or else you won’t be able to be sure your customer’s vehicle has strong enough welds.

Weld quality might also be affected by weld-through primer, according to Honda, which has expanded its restrictions on the use of that substance.

“Weld-through primer should not be used when doing MAG plug, MAG butt, or MIG Brazing,” Honda wrote. “Further study has shown that weld-through primers can negatively affect weld or joint quality.”

Honda also has some new details on MIG brazing and high-strength steel MAG welding wire requirements and/or availability. It also clarifies conclusively that steel up to 780 MPa can only by sectioned “if all three of the following conditions are met” (Emphasis Honda’s):

1. Sectioning must be done in a single-layer area of the part.

2. Multi-layer internal steel reinforcements and stiffeners must not be cut.

3. Do not section in load bearing areas, such as engine, transmission, or suspension mounting points.

So if you’re not 3-for-3, you can’t do it.

I-CAR also Sept. 1 reported that the manual added new sections on shielding gas and partial panel replacements.

To learn more about what’s changed, read the new Honda Body Repair News on welding and sectioning guidelines here. The Acura version can be found here. For repair procedures themselves, visit the Honda Independent Repair Website.

More information:

“Honda/Acura Has Released Two New Body Repair News Bulletins”

I-CAR Repairability Technical Support portal, Sept. 1, 2016

“Honda Body Repair Manual Welding & Sectioning Guideline Revisions”

Honda Body Repair News, August 2016

“Acura Body Repair Manual Welding & Sectioning Guideline Revisions”

Acura Body Repair News, September 2016

Honda Independent Repair Website

Images:

A welding mask sits in the SEMA Garage in 2016 during a tour. (John Huetter/Repairer Driven News)

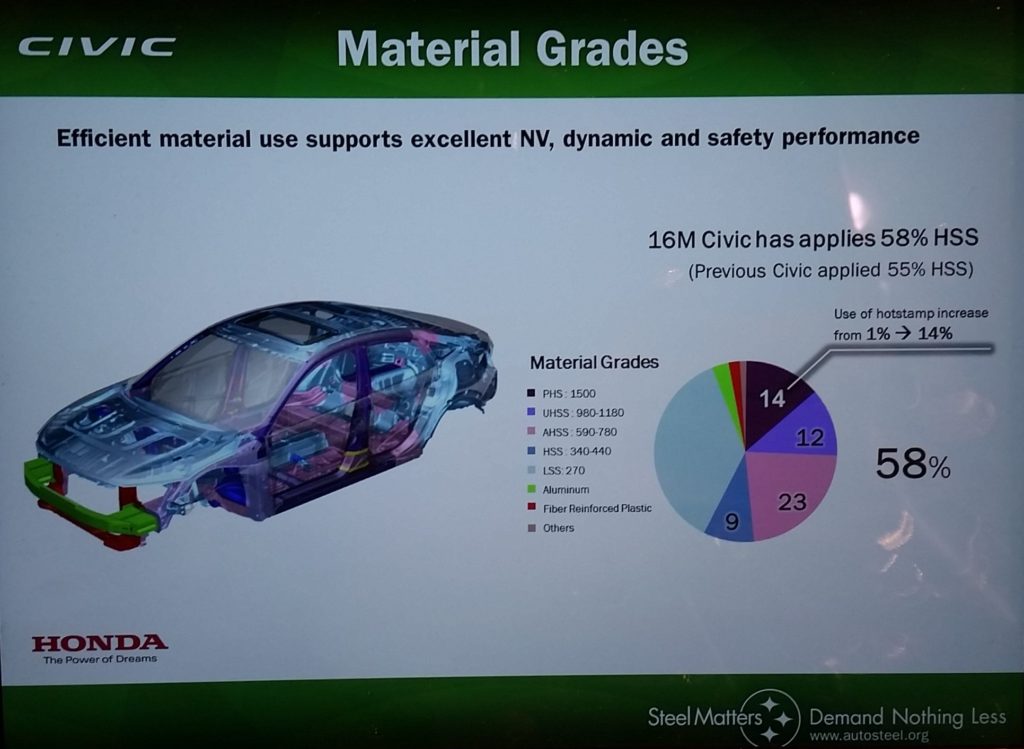

This Honda slide from the 2016 Great Designs in Steel demonstrates steel grades on the 2016 Honda Civic. (John Huetter/Repairer Driven News)