Alcoa announces new steel-aluminum riveting method, says it could work for aftermarket

By onMarket Trends | Repair Operations | Technology

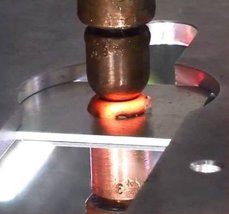

Alcoa last week announced what it called a “breakthrough” resistance spot riveting method to join aluminum and steel — and it’s one that could eventually be used by a collision repairer as well as an OEM factory.

“(W)e believe that RSR technology would be feasible for aftermarket use, but we have currently been focusing our resources on the manufacture of new vehicles using RSR technology,” Alcoa automotive and ground transportation products senior manager Shawn Murtha said in a statement Wednesday.

Alcoa, Honda R&D and Ohio State will now use Department of Energy funding to develop a prototype that uses the joining technique. Alcoa thinks it can have the rivets ready for the marketplace in 2018.

“We are working with Alcoa on advanced alloys and the RSR joining technology in conjunction with the Department of Energy because we are optimistic about the new value these advanced technologies will enable us to deliver to our customers in terms of performance and fuel efficiency,” Honda advanced body design technical leader Eric Boettcher said in a statement.

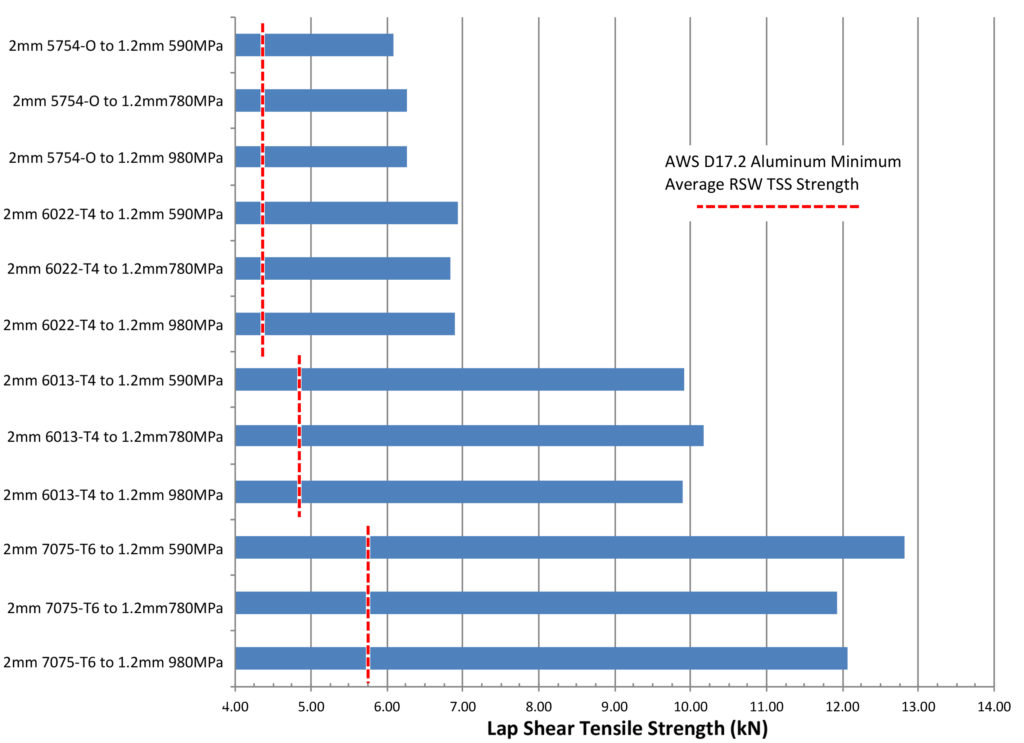

RSR riveting can connect basically every material automakers are considering for vehicles today and the next decade, according to Alcoa. Besides connecting aluminum to steels ranging from mild to ultra-high-strength, the rivets can also connect combinations of those metals with magnesium and composites like carbon fiber.

Alcoa hopes that mixed materials could someday knock the weight of an auto body down another 10-20 percent than what a solely high-strength steel structure would yield.

“It can be used in nearly any application, including frames, floors, closeout panels, pillars, roofs, seats and intrusion beams,” Alcoa wrote.

The aluminum giant boasted that not only were some riveted joints 10-20 percent stronger than what other methods could produce, RSR riveting and traditional spot welding equipment could be swapped in and out on an assembly line robot. That’s convenient for an OEM.

“Our RSR technology is going to be a powerful tool in the array of joining options for the automotive industry,” Alcoa Chief Technology Officer Ray Kilmer said in a statement. “As automakers continue to design vehicles using multi- material combinations, RSR technology is the ideal joining solution. It can easily accommodate stack up changes on the assembly line and it leverages existing welding robots outfitted with our automatic feeding systems.”

More information:

“ALCOA UNVEILS BREAKTHROUGH RSR™ JOINING SYSTEM FOR NEXT GENERATION LIGHTWEIGHT VEHICLES”

Alcoa, Sept. 14, 2016

Alcoa resistance spot rivet webpage

Featured images: Alcoa last week announced what it called a “breakthrough” resistance spot riveting method to join aluminum and steel — and it’s one that could eventually be used by a collision repairer as well as an OEM factory. (Provided by Alcoa)