‘Who Pays?’: 29.1% of shops find denib or finish sand/buff always needed

By onBusiness Practices | Education | Insurance | Market Trends | Repair Operations

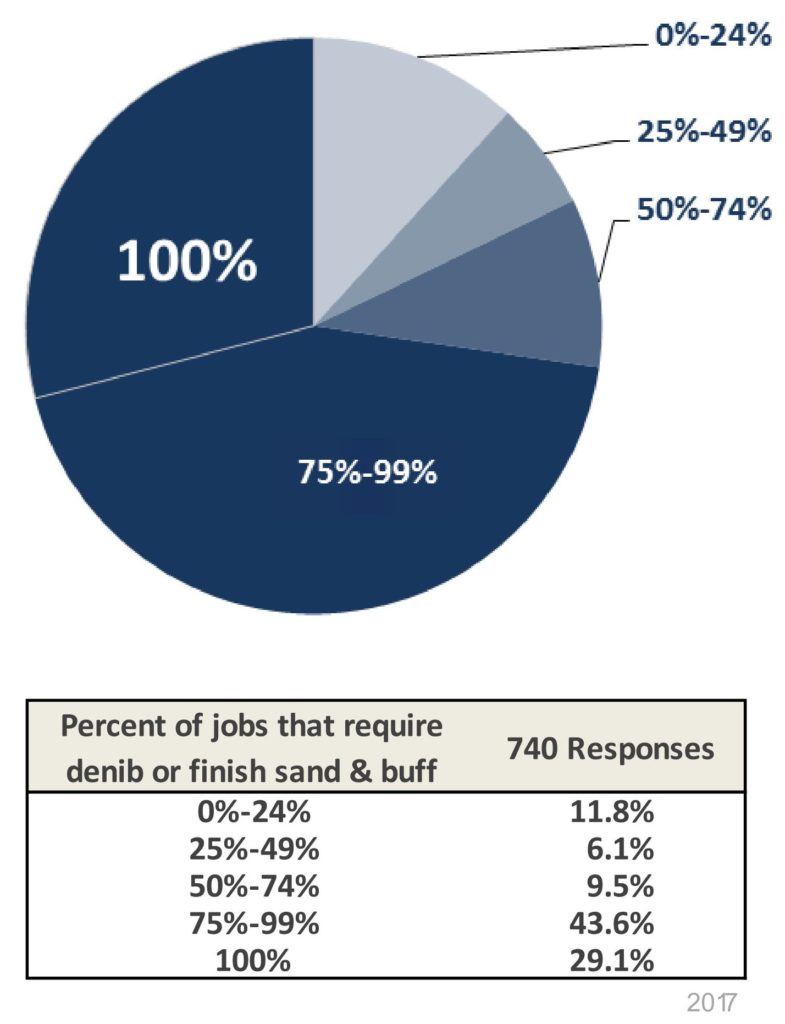

More than a quarter of 740 responding shops found either denibbing or finish sanding and buffing necessary on all jobs, according to the latest completed “Who Pays for What?” study.

Another 43.6 percent said they do at least one of those two operations on 75 percent to 99 percent of repairs.

The numbers fall off after that, with the next highest amount actually being the 11.8 percent who perform these operations less than 25 percent of the time.

The refinish-related survey by CRASH Network and Collision Advice was performed in January. Owners, managers or estimators can take the new “Who Pays?” survey on auto body operations through Sunday here. Participants receive a free copy of the results. Get past data here.

The refinish-related survey by CRASH Network and Collision Advice was performed in January. Owners, managers or estimators can take the new “Who Pays?” survey on auto body operations through Sunday here. Participants receive a free copy of the results. Get past data here.

The report on the January study explained why the survey split the denibbing and finish sanding and buffing procedures into two categories.

“It is important for shops to understand the difference between ‘denib’ and ‘finish sand and buff’ in order to charge the appropriate labor time based on what was done to the vehicle,” the report states. All three estimating system providers allow 30 percent of basecoat time for ‘finish sand and buff.’ But the systems each have a different formula (or none at all) for ‘denib.’ So the labor allowance varies significantly between ‘finish sand and buff’ and ‘denib.'”

Here’s the most recent descriptions we could find for AudaExplore, CCC and Mitchell (minor formatting changes), though we’d recommend accessing the respective P-pages directly through your estimating software to ensure you have the most current version:

Audatex

Audatex Database Reference Manual for Cars & Light Trucks on denibbing:

Nib sanding (or de-nib) is defined as the removal of isolated dirt and dust particles,

and polishing the affected area(s).

- Audatex’s formula for Final Sand and Buff does not apply to this operation. Additional steps or processes that may be required should be considered during estimate preparation.

AudaExplore on finish sanding and buffing:

Final Sand and Buff

This process, which may or may not be required, is defined as wet sanding the

entire panel by compound buffing and mechanical or hand polishing. Final sand

and buff is further defined as all of the above steps performed to the finished

surface for any reason, plus cleanup.

Final sand and buff can be estimated at:

30% of Audatex single-stage refinish labor (not including final wash).

CCC

CCC Motor Guide to Estimating on denibbing:

De-Nib & Polish

SPECIAL NOTATION:

Refinished panels may or may not require a varying amount of de-nibbing, a process used to remove small particles in final finish surface. The clear coat contains ultraviolet screeners and reducing the clear coat thickness (mils) may result in early paint failure. Follow vehicle manufacturer’s recommendations when performing this type of repairs. Calculations should be based upon the base refinish time outer surface only and should not include additions for clear coat, underside, inside or edges. In the event that this type of operation will be performed, MOTOR suggests the following formula be considered:

Each panel requiring de-nibbing (refinish or blend)

HOOD, ROOF, TRUNK LID, SPOILER

First panel add up to 20% of full base refinish time, each additional panel add up to10%

FENDER, DOOR, QUARTER PANEL, BUMPER COVER

First panel add up to 10% of full base refinish time, each additional panel add up to 5%

Included:

- Panel outer surface only

- Paint nib removal as required (spot only)

- Spot polish only

Does not include:

- Acid rain damage

- Full panel polish

- Overspray removal

- Removal of residual material from recessed edges and jambs if required

- Scratch damage

- Wash, clean, wax or detail entire vehicle prior to delivery if required

- Wet sand full panel

CCC on finish sanding and buffing:

Wet / Dry Sand, Rub-Out & Buff

SPECIAL NOTATION:

Refinished panels may or may not require a varying amount of wet sanding, compound rub-out, or buffing operations in order to match original finish texture. The clear coat contains ultraviolet screeners and reducing the clear coat thickness (mils) may result in early paint failure. Follow manufacturer’s recommendations when performing this type of repairs. Calculations should be based upon the outer surface only and should not include additions for clear coat, underside, inside or edges. Base refinish time does not include deduction for refinish overlap. In the event that this type of operation will be performed, MOTOR suggests the following formula be considered:

Refinished panels may or may not require a varying amount of wet sanding, compound rub-out, or buffing operations. In the event this type of operation will be performed, MOTOR suggest the following formula be considered.

Each panel requiring wet sand, rub-out and/or buff (refinish or blend)

- Add 30% of full base refinish time

Included:

- Compound, buff and/or polish as required

- Panel outer surface only

- Wet sand full panel as required

Does Not Include:

- Acid rain damage

- Overspray removal

- Removal of residual material from recessed edges and jambs if required

- Wash, clean, wax or detail entire vehicle prior to delivery if required

Mitchell

Mitchell P-pages on denibbing:

De-nib & Finesse

A labor time formula is provided should it be necessary to perform this operation. This procedure includes the removal of small isolated dust particles (nibs) and the application of a finishing glaze.

The performance of this operation is NOT INCLUDED in the Mitchell refinish

labor time.

The de-nib and finesse formula is intended to be calculated as a percentage of the base refinish hours excluding overlap and clear coat. It DOES NOT APPLY to edges, jambs, and undersides. For blended panels, the formula should be applied to the full panel refinish time. No deduction for refinish overlap should be taken.

De-nib and finesse outside surface area(s): Allow .2 per refinish hour (20%) to de-nib and finesse each surface area(s).

Mitchell on finish sanding and buffing:

Finish Sand & Buff

A labor time formula is provided should it be necessary to perform this operation. This procedure includes the removal of orange peel and any blemishes that affect paint texture in order to produce a smooth finish to the entire panel surface. This process is not limited to “nib sanding” or “finessing” which is the removal of isolated dirt/dust particles only. The performance of this operation is NOT INCLUDED in the Mitchell refinish labor time.

The finish sand and buff formula is intended to be calculated as a percentage of the base refinish hours excluding overlap and clear coat. It DOES NOT APPLY to edges, jambs, and undersides. For blended panels, the formula should be applied to the full panel refinish time. No deduction for refinish overlap should be taken.

Finish sand and buff outside surface area(s): Allow .3 per refinish hour (30%) to finish sand and buff each surface area(s).

Now that you know how to invoice it properly and support it with documentation, hopefully any friction between your shop and carrier is minimized.

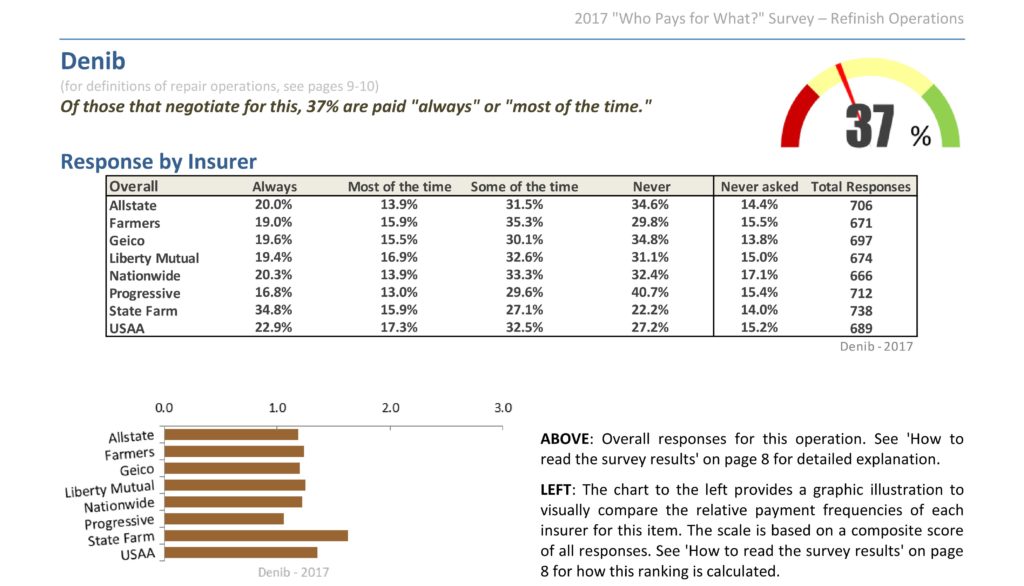

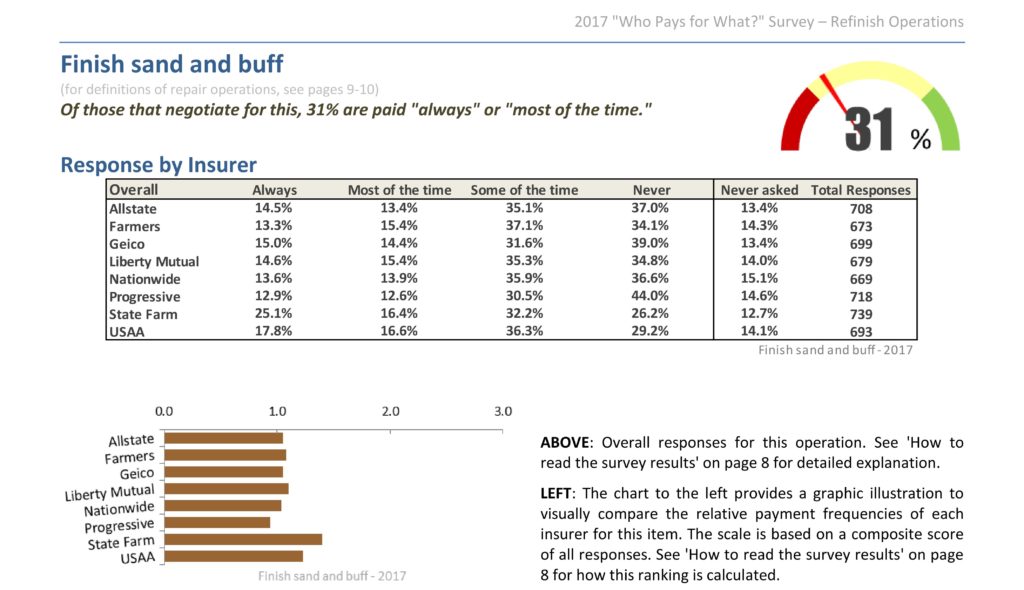

The “Who Pays for What?” study found that the Top 8 insurers are open to paying collision repairers who ask for reimbursement for these procedures, though perhaps not as consistently as they should be given shops’ reports of the necessity of at least one of these two operations.

More information:

Collision Advice-CRASH Network, March 31, 2017

Audatex Database Reference Manual for Cars & Light Trucks

Images:

If any readers would like to send us a better finish sanding and buffing photo than this stock art, we would love to use it. (Bogdanhoda/iStock)

More than a quarter of 740 responding shops found either denibbing or finish sanding and buffing necessary on all jobs, according to the January 2017 “Who Pays for What?” study. (Provided by Collision Advice and CRASH Network)

About 37 percent of the Top 8 insurers pay “always” or “some of the time” for denib when asked by shops, according to the January 2017 “Who Pays for What?” survey. (Provided by Collision Advice and CRASH Network)

About 31 percent of the Top 8 insurers pay “always” or “some of the time” for finish sanding and buffing when asked by shops, according to the January 2017 “Who Pays for What?” survey. (Provided by Collision Advice and CRASH Network)