CCC structural parts, Range Rover Velar doors in Audatex; air conditioning: 5 more tips from the DEG

By onAnnouncements | Associations | Repair Operations

The Database Enhancement Gateway, which allows repairers and insurers to make inquiries and suggestions of the Big 3 estimating providers at no cost, was augmented in 2015 to offer weekly tips for repairers on the Audatex, Mitchell and CCC programs online and through the Society of Collision Repair Specialists’ email list.

If you haven’t used the free service before to submit questions about estimating collision repair work or just browse responses to other carrier and shop questions, check it out. It’s a good way to find IP best practices and help write the most accurate estimates or appraisals possible.

Here’s some areas spotlighted as tip-worthy by the DEG. To receive the tips as soon as DEG releases them, like/follow the DEG’s Facebook and Twitter feeds. (It also posts videos to a YouTube channel once in a while.) Or just browse the more than 10,000 inquiries and responses in the database and see what else you learn.

Mitchell: When seam sealer is and isn’t included

Mitchell does bake seam sealer/caulking time into its labor times for welded panels, but there’s a lot of other instances where seam sealer or related operations wouldn’t be included, the Database Enhancement Gateway pointed out in February, quoting Mitchell’s P-pages.

“The labor time for welded panels includes the application of caulking/seam sealer to the joints, gaps and seams of welded panels to achieve water sealing,” Mitchell’s P-Pages state. “It does not include the use of a caulking/seam sealer product as undercoating or sound deadening. It does not include any necessary masking, set-up and clean-up of an application tool, test patterns or application of material to duplicate factory look, texture and color or to create noise and vibration absorbing properties for the panel(s).”

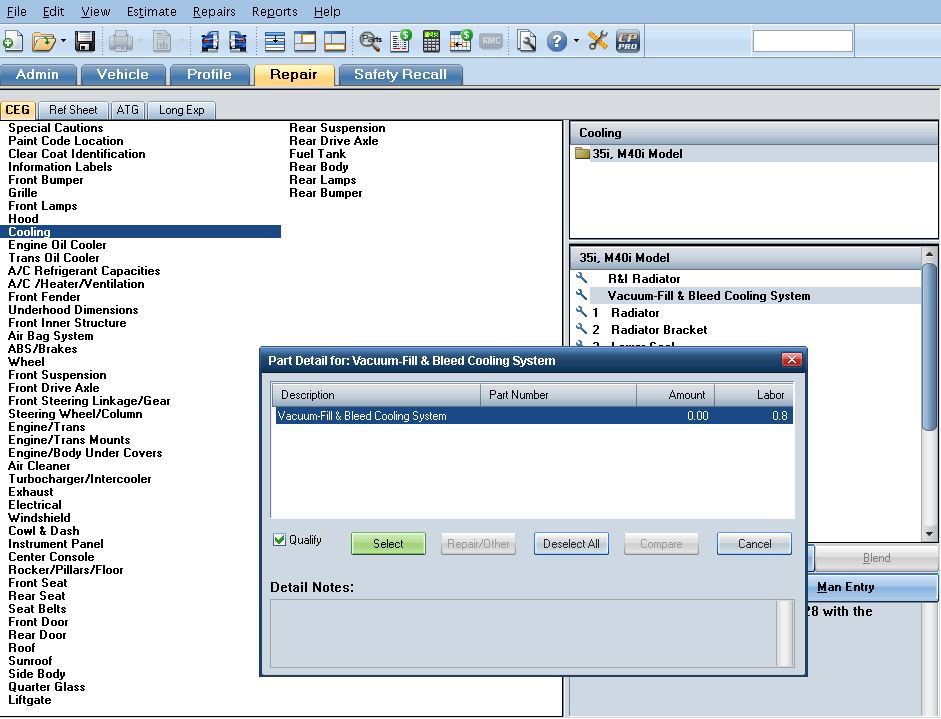

Mitchell: Coolant fill not included in fill and bleed

“When cooling radiators need to be R/I or R/R during the repair process, the coolant fill may be required to perform Vacuum-Fill & Bleed operation,” the DEG wrote in March. “If this process is required, this is NOT INCLUDED and would need to be selected from the Add To section of the part selection screen. This can be found under the Cooling’ section in the of the part selection menu.”

In case you were interested, Mitchell’s general radiator R&R instructions state that “Remove and install or replace: Shroud, Electric fan if necessary,” “Disconnect and connect: Hoses at radiator, Transmission coolant lines,” “Drain, refill and check coolant” and “Visual check for leaks” are included.

However, in describing not-included operations, it states, “Remove and install or replace: Fan, Pulley, Fan clutch, Belts, Hoses if necessary; add.1 hour for one,.2 hour for all hoses”; “Pressure test system if necessary (example: check for damage due to collision); add.3 hour”; and “Operational steps for bleeding air from the cooling system (If necessary).”

A/C in all three systems

The DEG also instructed that “Air conditioning systems which have been damaged during a collision or a system that has been open and exposed, and not immediately sealed, the receiver drier or desiccant element should be replaced,” calling this tip applicable to all three estimating systems.

Mitchell, for example, offers the “IMPORTANT REMINDER” (emphasis Mitchell’s) that “If all refrigerant has been lost by collision damage, or if refrigerant lines have been opened and not immediately sealed, the receiver drier should be replaced. Replacement of collision damaged parts on a system that is still pressurized should not require replacement of receiver drier.”

The DEG also said that for all three estimating services, “During A/C r134a and R1234yf evacuate and recharge process, testing for leaks is NOT INCLUDED. Cost of refrigerant, oil and seals are NOT INCLUDED in labor times.”

Audatex: Not-included door shell operations

Audatex recently increased its labor allowance for door shell operations on a 2018 Range Rover Velar, according to a February inquiry the DEG highlighted in a March tip.

“Shop is contesting labor 4.3 hours for door shell replacement on vehicle,” the DEG user wrote. “It is not possible replace door on this vehicle and align and transfer attached parts as listed in the front door section. Please please advise what labor operations should be considered separate in addition.”

The user said the actual time necessary for the work would be 6.7 hours.

“Other database range from 6.1-7.1 labor time,” the user wrote. “Please update to reflect actual and correct labor time or suggest what additional labor considerations should be considered in door shell replacement for such low hours on base time.”

“We have reviewed the current OEM service information for the DOOR SHELL,REAR (GN 0287/0288) and DOOR SHELL,FRONT (GN 0207/0208),” Audatex wrote. “The DOOR SHELL,REAR (GN 0287/0288) labor allowance has changed from 3.6 hours to 4.2 hours and the DOOR SHELL. Additionally, the DOOR SHELL,FRONT (GN 0207/0208) labor allowance has changed from 3.8 hours to 4.4 hours for LT side and from 3.7 hours to 4.3 hours for RT side. All times are before option conditioning and/or overlap considerations. The change will appear on the February 2018 release.

“In response to additional DEG questions: Weatherstrip measuring is included in Audatex provided labor values, whether installing or transferring to a new panel. Weatherstrip cleanup time is not an included operation, please see the DBRM Section 4-3 Replacement & Recycled Operations. Door shell transferal of small grommets, clips or fasteners is not included in the Audatex provided labor values.”

CCC: What’s structural?

Obviously, the ultimate arbiter of what’s structural and what isn’t on a particular vehicle will be the OEM itself.

But CCC will help provide some guidance with its “(S)” designation on estimates, though it too notes in its P-pages, “CLASSIFICATION INDICATORS ARE PROVIDED FOR YOUR CONVENIENCE AND MUST ONLY BE CONSIDERED A HELPFUL GUIDE.”

“The purpose of classifying components is to describe physical properties of the component, and classifications may inform the estimator that specialized technician skill levels and/or tools may be required,” CCC writes before that warning. “Indicators are not intended to determine labor rates charged, or to be inclusive of all components. Any additional component classification(s) should be determined after an on-the-spot evaluation of required repair procedures.”

The DEG in February drew insurers and repairers’ attention to CCC’s definition of “structural” — “Components that provide a load bearing foundation for the purpose of safety and/or stability” — and its lengthy “Structural Component Identification” section.

“Structural component identification information as presented in I-CAR Enhanced Delivery programs,” CCC writes.

“Welded structural parts can be made from different types of metal; identification is not based on metal type. Replacement requires specific measuring equipment and vehicle dimensions must be correct. If improperly repaired, road performance and crashworthiness of the vehicle may be affected. Airbag deployment may also be affected.”

CCC states welded unibody structural parts “typically include” the aprons/strut towers, including the rear ones; center, corner, hinge and lock pillars; front, rear and upper rails; radiator core supports, rocker panels and suspension crossmembers. Welded body-on-frame structural parts “typically include” the apron assembly; cab corner and back panel (on a pickup truck); center, corner, hinge and lock pillars; radiator core support; rear and upper rails; and rocker panels.

Some parts that are bolted, bonded or welded may add structural integrity to a vehicles body. These parts are made from different types of materials and vehicle dimensions must be correct before replacement. If improperly repaired, road performance and crashworthiness of the vehicle may be affected. Airbag deployment may also be affected.

However, CCC also observes for both body types that “Parts that may add structural integrity to a vehicles body may include” cowl assemblies; dash, floor, quarter, rear body and roof panels; bolt-on engine cradles, impact bars and radiator core supports; perimeter frames, and urethane-bonded stationary glass.

“Shops may also notice in the Rates section the ability to charge a different rate for this type of repair if elected,” the DEG wrote of structural work.

It quoted CCC’s response to two 2018 inquires, one regarding a 2015 Range Rover and the other involving a 2017 GMC Terrain.

“Classifications are not inclusive of all components. Usage of MOTOR component classifications to determine labor rates is at the sole discretion of the end user(s),” CCC wrote in both cases. “Please note that any component can be designated as mechanical by the end user. This would be inclusive of Mechanical, Structural, Frame, glass, etc. in the database.”

Have a question?

Have a question about AudaExplore, Mitchell or CCC? Submit inquiries to the DEG here. Inquiries, like answers, are free.

More information:

Database Enhancement Gateway homepage

Images:

A 2018 Range Rover Velar is shown. (Provided by Jaguar Land Rover)

Auto body shops wishing to buy the common 10- or 30-pound tanks of R-1234yf or R-134a refrigerant needed to have at least one air conditioning-certified technician by Jan. 1, 2018. (hedgehog94/iStock)

“When cooling radiators need to be R/I or R/R during the repair process, the coolant fill may be required to perform Vacuum-Fill & Bleed operation,” the Database Enhancement Gateway wrote in March. “If this process is required, this is NOT INCLUDED and would need to be selected from the Add To section of the part selection screen. This can be found under the Cooling’ section in the of the part selection menu.” (DEG screenshot of Mitchell)