BMW deploys robots to perform paint inspection procedures

By onBusiness Practices | Market Trends | Technology

BMW is using robots to inspect, process and mark painted vehicle surfaces at its Regensburg, Germany plant and says it’s the first automaker in the world to use artificial intelligence (AI)-based technology at this scale.

The OEM said AI-controlled robots are processing each vehicle individually in production to meet specified quality standards. It said the approach has proven successful by creating shorter lead times and a “consistently high level of vehicle surface quality.”

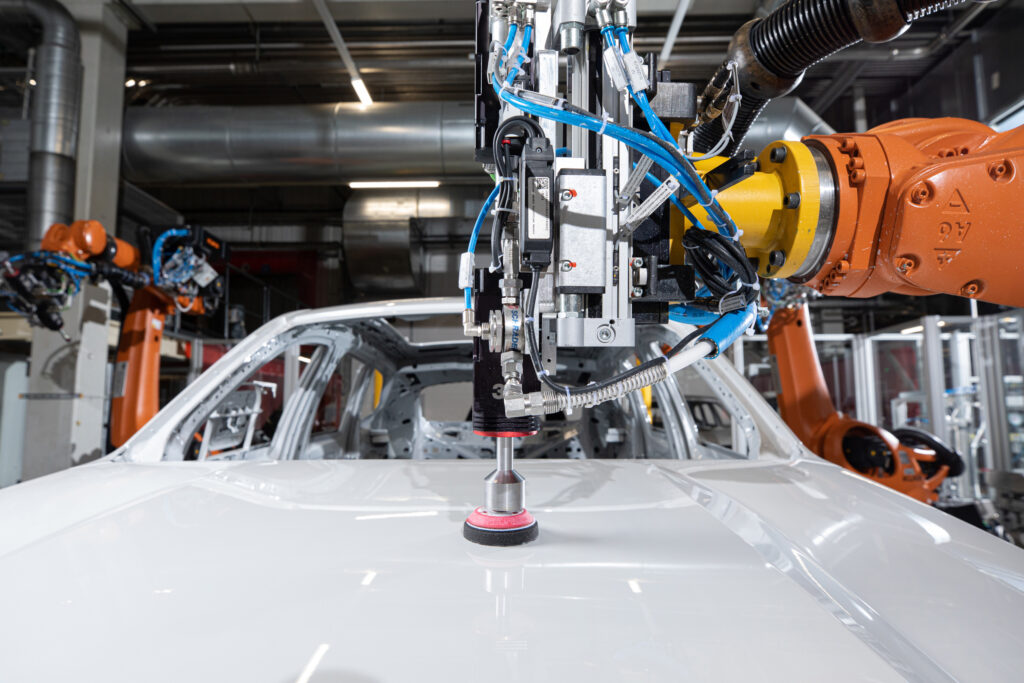

“The scene resembles a well-rehearsed play: Four robots stand in the processing booth, surrounding a freshly painted body,” BMW says in a press release. “As if on command, the robots begin working on the surface of the body. They sand it, apply the polishing compound, polish, change the attachments and switch out the sandpaper.”

BMW said it has been using automated surface processing at its Resenbug plant since last March. Before surface processing begins, an automated surface inspection identifies and records features that require processing after the application of the topcoat, BMW said.

During the surface inspection, the system uses special technology to identify flaws. It does so by projecting black and white patterns onto the vehicle’s surface and allowing cameras to scan it to “detect even the slightest variation in the reflective paintwork,” BMW said.

The camera then logs deviations and transfers the data to a connected computer system, which saves the coordinates and size of the flaws, creates a 3D image of it, and then classifies it, the OEM explained.

“What is unique here is that the robots work on each body exactly where needed—because the tiny specks and bumps that can appear after the topcoat is applied and that we want to remove are in different spots on each vehicle,” said Stefan Auflitsch, head of production paint application and finish at BMW’s Regensburg plant.

“Robots are normally programmed to follow the same pattern until they are reprogrammed. Using artificial intelligence allows them to work in a more tailored manner. With up to 1,000 vehicles going through the finishing process every working day, that adds up to 1,000 unique processes.”

Daniel Poggensee, a structural planner for surface technology, said BMW channeled the experience of human employees to create the algorithm, which can now independently determine which areas need attention post-processing.

“The system already knows as much today as our best employees combined,” Poggensee said. “We used the knowledge of our entire team to finalize the system; the functioning of the equipment relies on our associates’ unique expertise.”

But the robots can’t do everything, BMW said. They aren’t able to process edges of the body or the millimeters of space close to doors and other joints, nor can they handle the fuel cover.

It means people are still required to make the finishing touches and give the body a final inspection, BMW said.

Even though people are tasked with finishing the job, they’re doing so with the help of AI, which uses a laser projector to show the relevant areas of the body surface, BMW said.

Poggensee said the OEM is now brainstorming more ways to improve the AI-driven process in the future.

“On the one hand, thanks to the data in the cloud, we expect to soon be able to intervene in the process even earlier if there are any inconsistencies – which will enable us to prevent faults from occurring in the first place.

“On the other, the equipment used should be able to automatically record operations performed by employees – so they do not have to go back and forth between the body and the computer for documentation. In addition to saving time, this also reduces complexity and increases the added value.”

BMW’s Regensburg facility is the first plant to use this three-stage automated process in standard production. It is also currently being rolled out to other BMW plants. Its models are coated using 3M Finesse-it Robotic Paint Repair System

Images

All photos depict automated surface processing at a BMW plant./Courtesy BMW