BMW testing all-solid-state battery cells in BMW i7

By onAnnouncements | International | Technology

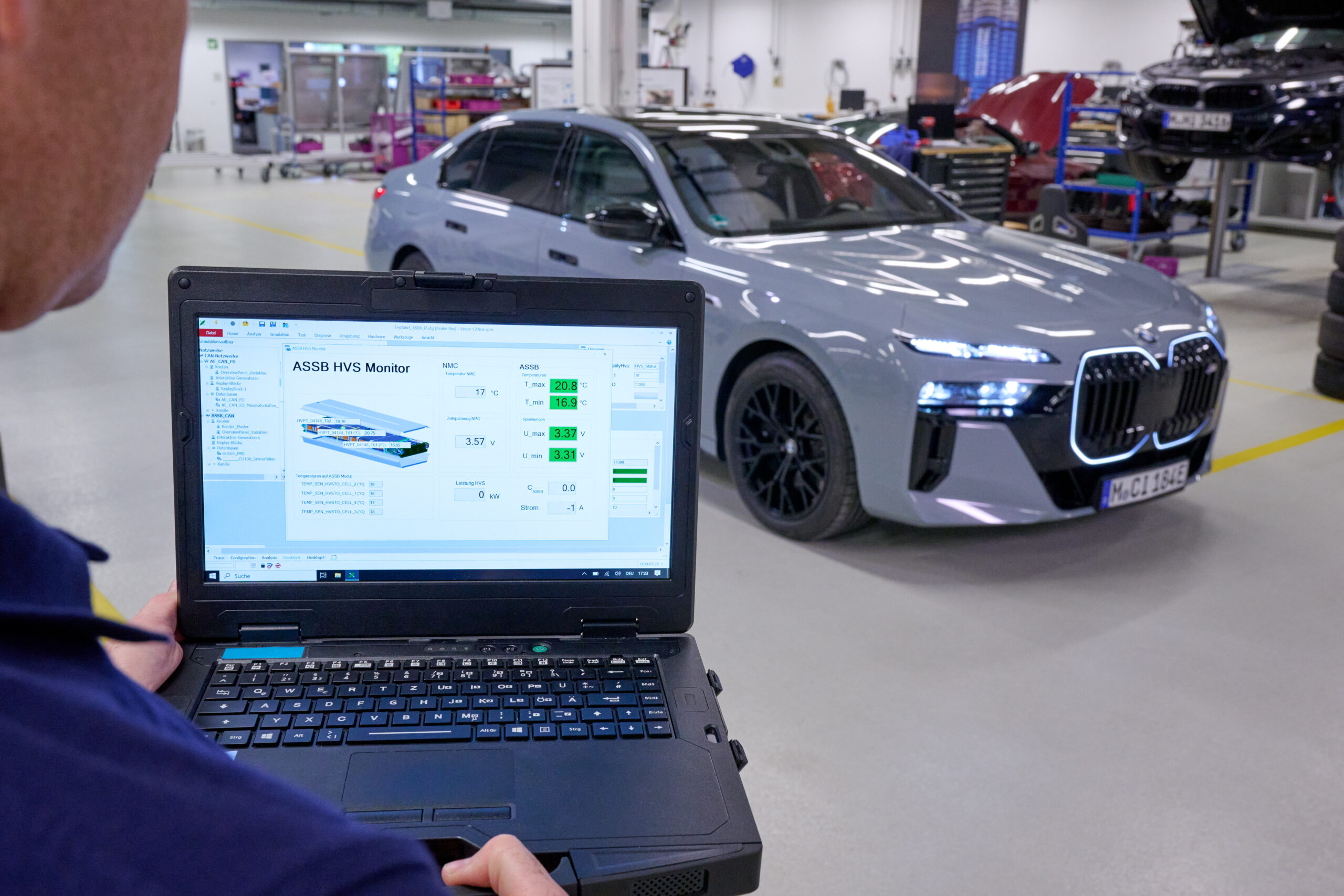

The BMW Group is bringing large-format, pure all-solid-state battery (ASSB) cells from Solid Power to its test vehicle, a BMW i7.

BMW says the potential benefits of ASSB technology are higher energy density in a very compact storage system, meaning the potential to achieve longer ranges without the disadvantages of added weight. The testing vehicle is currently operating in the Munich area.

Since 2022, the BMW Group and Solid Power, Inc. have ramped up the development of their ASSB technology through their technology transfer agreement.

“Solid Power is extremely proud that our partnership with BMW has resulted in the first demonstration of truly all-solid-state battery cells in a vehicle,” said John Van Scoter, Solid Power’s president and CEO, in a press release. “We believe in the promise of ASSBs and continue to drive innovation of our sulfide electrolyte in support of that future for EVs.”

According to the release, the concept battery integrated in the BMW i7 test vehicle combines proven Gen5 construction principles (prismatic cells in modules) with new, innovative module concepts for integrating ASSB cells from Solid Power. The management of cell expansion will be investigated, as well as how the operating pressure is controlled and how to adjust the temperature conditions.

Further development steps are required to implement ASSB technology in a competitive overall storage system, the release says.

“Our BMW i7 ASSB test vehicle on the road is a perfect example of the BMW Group’s technology-open mindset,” said Martin Schuster, BMW Group’s battery cell and cell module vice president, in the release. “We are continuously advancing the development of new battery cell technologies and are constantly expanding our know-how with valuable partners such as Solid Power.”

Using solid power cells with sulfide-based electrolytes and their complete integration into a battery pack will provide the BMW Group with further important findings in the test program over the coming months, the release says.

BMW says it will operate a solid cell prototype line at the Cell Manufacturing Competence Center in Parsdorf based on a research and development license and using the experience and expertise of Solid Power.

The BMW Group has been steadily expanding its expertise in battery cell technology since 2008, and in 2019, brought all of the aspects under one roof at the Battery Cell Competence Center (BCCC) in Munich. The BCCC covers the entire value chain, from research and development to battery cell design and production capability, the release says.

To implement innovations in battery cell technology quickly and efficiently, the BMW Group cooperates in a network of around 300 partners, including established companies, startups, and universities.

“The cooperation with Solid Power underlines the BMW Group’s battery strategy — to further develop innovative battery technologies on equal footing with leading partners in the industry,” the release states. “This strategically strong position in the value chain ensures the BMW Group access to all new and innovative battery cell research worldwide.”

Images

BMW i7 with all-solid-state battery cells from Solid Power undergoing road testing (Provided by BMW)