Rivian simplifies door handle trim cover refinish procedure after industry feedback

By onAnnouncements

Rivian’s collision and engineering teams have found a solution to the tedious process of refinishing the door handle trim cover on R1T and R1S vehicles after listening to shop feedback.

Dan Black, Rivian service engineering collision senior manager, said previously shops couldn’t remove the door handle trim for refinishing because of a near field communication (NFC) chip in the handle.

Rivian door handles are flush with the vehicle when locked. The NFC technology detects when the vehicle’s owner is near via their key card, fob, or phone. The chip then notifies the door handles to present themselves to the owner.

“This creates more risk when it goes through the process of repairing,” Black said.

A cover plate is snapped onto the door handle to make its appearance cohesive, Black said. He said the plate is assembled to the door handle with a screw on the backside at the supplier level.

“There is no access to that fastener on that door handle,” Black said.

Previously, shops needed to paint the door plate while it was attached to the door handle.

“You have to do a lot of masking to make sure you don’t have any bleeds or overspray,” Black said. “Odds are you have to blend something and you have to refinish that door handle cover to look consistent across that repair.”

Black said Rivian received shop feedback about the difficulty of refinishing the door handle trim cover, including during an OEM Collision Repair Technology Summit at the 2024 SEMA Show in Las Vegas.

“We went through a lot of challenges with engineering to discuss what we were hearing from the industry,” Black said.

Rivian needed to eliminate any risk associated with removing the door trim, he said. This included a series of validations to make sure that the repair wouldn’t introduce any function issues to the door handle.

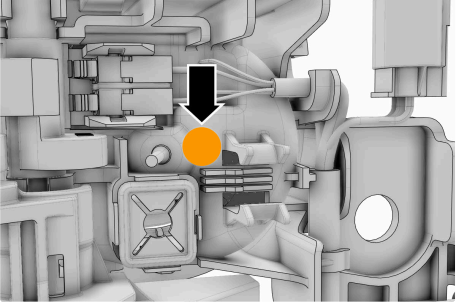

It was determined that a hole could be drilled in the backside of the door handle to gain access to the trim fastener, he said.

A special tool can then be used to pop the trim off of the door handle he said.

“It is a really smooth process,” Black said.

He added that the door trim can then be painted separately from the door handle and if a handle needs to be replaced, the trim can be removed and swapped to the new mechanism.

Black said removing the trim likely saves at least a half an hour of masking, which was a tedious process with fine-line tape.

“It was incredibly difficult to execute it in the time allocated to execute it,” Black said. “Now that we have eliminated those concerns they can have the optimal workmanship.”

Repair processes can evolve with industry feedback, he said. He said Rivian’s collision engineering team is always considering safety, quality, and shop environment when creating the processes.

“The feedback loop never stops,” Black said. “We know the realities of what you are up against. We try to catch everything but we don’t.”

Rivian officials explained the three-year process they undertook to research, develop, validate, and publish new repair procedures during the OEM Collision Repair Technology Summit.

SCRS promoted the session as an inside look into the value of OEM repair information and how procedure development and testing play a critical role in safe and proper repairs.

Recordings of the summit sessions are now available to watch online.

The summit package includes three hour-long sessions presented live at the 2024 SEMA Show for $99. Each session can also be purchased individually for $49. Current SCRS members are entitled to a 20% discount on purchases in the SCRS Online Education Platform.

IMAGES

R1S photo courtesy of Rivian