Anderson points out Toyota requirements on welding, bonding

By onBusiness Practices | Education | Repair Operations | Technology

Toyota’s collision repair manuals and CRIB bulletins contain the necessary specifications and precautions for auto body shops to perform proper welding and bonding, Collision Advice CEO Mike Anderson demonstrated during a webinar last month.

That shouldn’t come as a huge surprise; what’s the point of having a repair manual if such information wasn’t included? However, it seems like some shops might not be tapping this crucial resource and find themselves overlooking some of the trivia and lessons Anderson shared.

Check out Anderson’s free webinar on Toyota’s official OEM repair procedure website “TIS” (http://techinfo.toyota.com) and make sure you’re not making incorrect collision repair decisions. Register for the next webinar discussing FCA’s collision repair repair procedures by signing up here for the 1 p.m. March 23 course.

The decision tree on the left-hand side of Toyota’s collision repair manual pages features a “precautions for welding” cheat sheet with explanations and precautions, such as a requirement to refinish any paint film (weld burn) damage, Anderson explained.

The precautions explain what type and how many welds should be used. For example, Toyota wants more plug welds and specifically 1.3 times more spot welds than factory on the 2018 Camry.

Another part of the decision tree gives you specific body weld points and types and other joining requirements, such as where and what type of adhesive should be used. Anderson at one point mentioned 2017 Camry quarter panel instructions which call specifically for only 3M 8115 panel bonding adhesive in certain areas.

“It’s always important to only use the adhesives that are approved by the vehicle manufacturer,” Anderson said.

Disregard another company’s claim that a particular adhesive will work for a particular situation, he advised. If the OEM didn’t approve it, “do not use that stuff.”

Most adhesives have specific cure times, according to Anderson. The aforementioned 3M 8115 panel bonding adhesive instructions state that the vehicle must cure for either 60 minutes at 140 degrees Fahrenheit (60 degrees Celsius) or 12 hours at 77 F (25 C). The adhesive doesn’t completely harden for 90 minutes at 140 F or 24 hours at 77 F, according to TIS.

Anderson said “I hate to tell you” how many shops he’s visited where a vehicle’s adhesive was applied before lunch and sat around curing during that time — before being moved right to the paint shop.

“You’re moving that vehicle before it’s completely cured,” Anderson said. Always check the cure time first, he said.

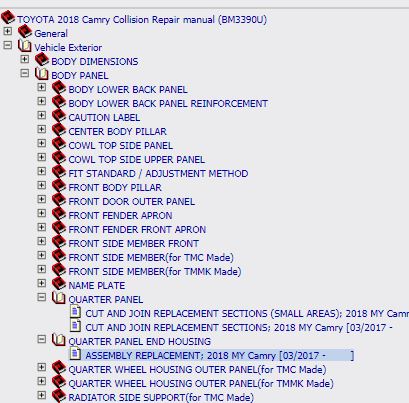

He said the decision tree also will offer “cut and join replacement sections” instructions if certain areas can be sectioned, while nonsectionable parts will offer “assembly replacement” steps.

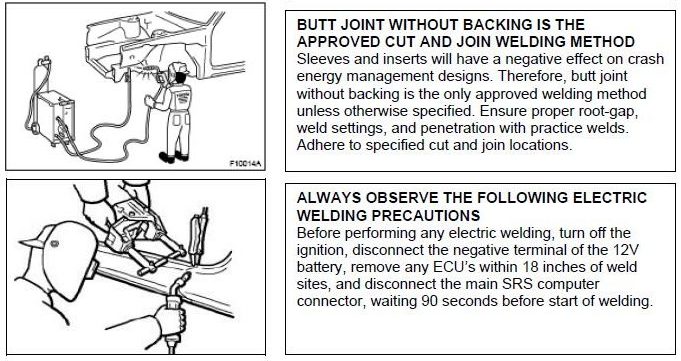

Anderson also directed shops to take note of Toyota CRIB No. 161, which reminds repairers to remove all electronics within 18 inches of the welding point, not the 12 inches required by other OEMs and described as a general rule of thumb by I-CAR.

“This is really important,” Anderson said.

“Before performing any electric welding, turn off the ignition, disconnect the negative terminal of the 12V battery, remove any ECU’s within 18 inches of weld sites, and disconnect the main SRS computer connector, waiting 90 seconds before start of welding,” CRIB No. 161 states.

He also observed that both Toyota’s training manual and CRIB No. 181 hold that collision repairers must perform destructive test welds.

“You must always perform a destructive test to your practice welds

before performing final welds on a vehicle,” states Toyota’s “Welding Techniques for Collision Repair: Weld Integrity,” which is also available on TIS. “The tear out size and shape of MIG plug welds and STRSW determines the weld integrity. The break point for a butt weld determines its strength.”

“Appearance alone does not validate the strength of a weld,” CRIB No. 181 states. “Weld strength must be validated by tuning the welder and performing destructive testing. Tuning the welder and destructive tests must be performed on metal of the same thickness and composition as that of the component being replaced.” (Emphasis Toyota’s.)

Toyota doesn’t demand specific welding equipment by brand (though it does so for adhesives), instead providing specifications, according to Anderson.

Toyota Collision Repair and Refinish Training Administrator Agustin Diaz said a manual might describe a particular minimum amperage or a certain nugget size.

Anderson also discussed how OEM repair procedures could, if applied correctly, make a decision for a shop or adjuster on something like a recycled quarter panel.

CRIB No. 181 states “STRSW substitutions should match factory spot welds in size, strength and appearance. If replacement welds are larger or smaller, resize electrode contact tip to match. Do not STRSW over factory weld locations.”

“At the end of the day, I don’t believe my opinion means anything,” Anderson said. All that matters is “what I can prove, substantiate or justify,” he said, and asked if it would be possible to match factory spot welds in size, strength or appearance on a used quarter panel. “You would not” be able to do so, he said.

Toyota OEM repair procedures are also clear about what kind of welds they don’t want done. CRIB 161 outright bans backings or sleeves on butt joints, warning they would affect crash energy management, Anderson pointed out. If you write that on an estimate, “that is an improper repair,” he said.

“Sleeves and inserts will have a negative effect on crash energy management designs,” Toyota wrote. “Therefore, butt joint without backing is the only approved welding method unless otherwise specified. Ensure proper root-gap, weld settings, and penetration with practice welds. Adhere to specified cut and join locations.”

More information:

Toyota “TIS” OEM repair procedure website

Toyota TIS tutorial video (no subscription required)

“Collision Advice Learn to Research, Research to Learn – Toyota TIS”

Mike Anderson YouTube channel, Feb. 26, 2018

Images:

In 2015, the Toyota Mississippi production line, pictured, celebrated the creation of its 500,000th Corolla. (Provided by Toyota)

The decision tree on the left-hand side of Toyota’s collision repair manual pages features a “precautions for welding” cheat sheet with explanations and precautions. (Screenshot from Toyota TIS at techinfo.toyota.com)

Another part of the decision tree gives you specific body weld points and types and other joining requirements, such as where and what type of adhesive should be used. Collision Advice CEO Mike Anderson discussed how the decision tree also will offer “cut and join replacement sections” instructions if certain areas can be sectioned, while nonsectionable parts will offer “assembly replacement” steps. (Screenshot from Toyota TIS at techinfo.toyota.com)

Toyota CRIB No. 161 reminds repairers to remove all electronics within 18 inches of the welding point, not the 12 inches required by other OEMs and described by I-CAR, according to Collision Advice CEO Mike Anderson. CRIB 161 outright bans backings or sleeves on butt joints, Anderson pointed out. If you write that on an estimate, “that is an improper repair,” he said. (Screenshot from Toyota TIS at techinfo.toyota.com)