Molding/decal cheat sheet, tall vehicles, mirrors in Audatex: 5 more DEG tips

By onAnnouncements | Associations | Business Practices | Education | Market Trends | Repair Operations | Technology

The Database Enhancement Gateway, which allows repairers and insurers to make inquiries and suggestions of the estimating providers at no cost, offers weekly tips for repairers on the Audatex, Mitchell and CCC programs online and through the Society of Collision Repair Specialists’ email list.

If you haven’t used the free service before to submit questions about estimating collision repair work or just browse responses to other carrier and shop questions, check it out. It’s a good way to find IP best practices and help write the most accurate estimates or appraisals possible.

Here’s our latest monthly roundup of areas spotlighted as tip-worthy by the DEG. To receive the tips as soon as DEG releases them, like/follow the DEG’s Facebook and Twitter feeds. (It also posts videos to a YouTube channel once in a while.) Or just browse the more than 13,000 inquiries and responses in the database and see what else you learn.

Mirror overhauls in Audatex

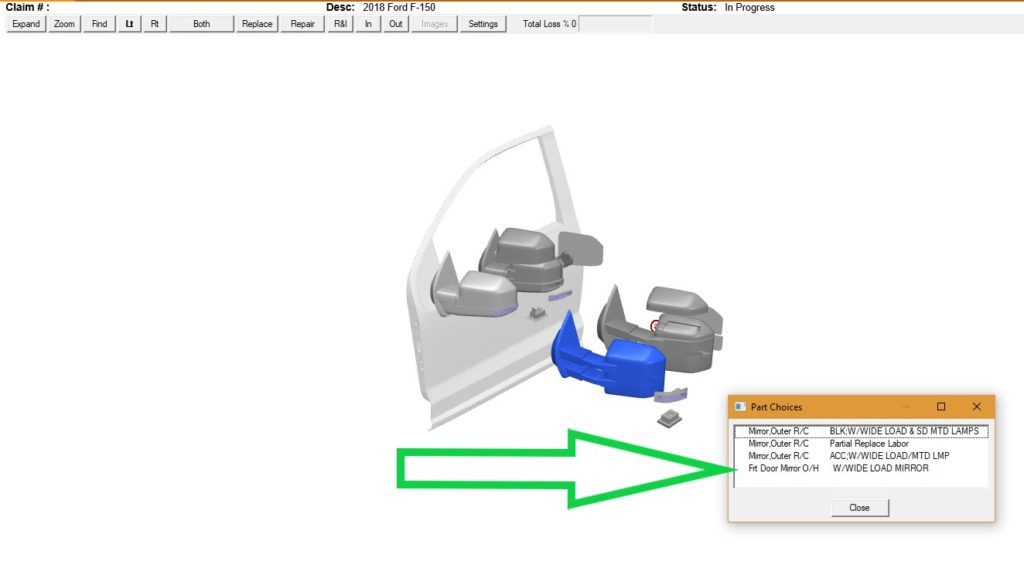

A January Database Enhancement Gateway tip reveals Audatex had begun supporting some mirror overhaul operations with times.

The decision seems like a natural extension of the kind of technology being packed into what used to be a relatively simple part.

“Mirror overhaul applies when a mirror assembly consist of many individual parts, i.e. side markers, cameras, puddle lamps, motors, sensors, etc.,” Audatex wrote. “The overhaul operation includes the labor time to transfer individual mirror components from the damaged mirror to a new one. This new operation eliminates the need to search and add R&I for each mirror component, which in turn saves time and increases accuracy.”

The first wave of files with the new mirror information include various years of the Honda Accord, Nissan Altima, Ford Escape and the Ford F-150 Super Crew and Standard Cab. Audatex will add mirror overhauls to relevant new or updated files going forward.

CCC ‘estimate sequence’ video

The DEG last month offered estimators and adjusters a handy video with information about managing one’s estimate sequence in CCC.

“It is important for estimators to use the database with ‘estimate sequence’ in mind, which is the order that the repair plan is developed: front to back or back to front,” the DEG wrote in a January tip. “Following the sequence provided by the database will also allow the database to properly calculate any overlap for adjacent panels for both refinish and panel replacement procedures.”

As CCC explains in its P-pages:

Listed under each basic assembly are the related and component parts. List the damage according to the basic assembly, taking the basic item first. Then, starting from the outside of the vehicle and working inward, list everything attached to it which is damaged. By following this procedure, you will make a more thorough inspection.

For instance, on an estimate involving front fender damage, inspect as shown:

Fender

molding

nameplate

emblem

Fender Liner (Minor formatting edits.)

Mitchell parts schematics

The CCC video was one of two films released by the DEG last month on its YouTube channel.

The other video, posted Jan. 31, taught Mitchell users about how to quickly find out about and navigate to multiple schematics within a single system. It illustrated this with a pickup bed and rear suspension.

“Mitchell users may find that not every part is shown when selecting a vehicle part group, and will have to go down the list of part descriptions to see if additional parts exist,” the DEG wrote. “Users can quickly identify if multiple parts schematics exist for that group by locating a page number in the schematics screen menu.”