Hyundai & Kia cut EV aerodynamic resistance, Stellantis unveils BEV platform

By onMarket Trends | Technology

Hyundai Motor Co. and Kia Corp. have unveiled an “Active Air Skirt (AAS)” technology that they say minimizes the aerodynamic resistance generated during electric vehicle (EV) high-speed driving, effectively improving driving range and driving stability.

AAS controls the flow of air entering through the lower part of the bumper and controls the turbulence generated around the vehicle wheels by operating variably according to the vehicle speed, according to a joint news release from the automakers.

“In the EV era, competition to secure a better driving range from a single charge has become fierce, making the relationship between vehicles and aerodynamics even more important,” the release states. “Furthermore, aerodynamic performance has a significant impact not only on power performance but also on driving stability and wind noise.”

Manufacturers are exploring various measures to reduce the coefficient of drag (Cd), which is the resistance coefficient of the air acting in the opposite direction of the vehicle’s motion.

AAS is installed between the front bumper and the front wheels of the vehicle and is hidden during normal operation, but it operates at speeds over 49mph when the aerodynamic resistance becomes greater than the rolling resistance and is stored again at 43mph. The difference in deployment and storage speeds is to prevent frequent operation in specific speed ranges.

Also, AAS only covers the front part of the tires without completely covering the front is related to the characteristics of Hyundai Motor Group’s E-GMP platform for EVs. This is because it is more effective in improving aerodynamic performance to only cover the tire part since the platform floor is flat. This also functions to enhance the downforce of the vehicle, thereby improving vehicle traction and high-speed stability.

AAS can also operate at speeds over 200 km/h. This was possible thanks to the application of rubber material on the lower part, which reduces the risk of external objects splashing and damaging while driving at high speeds and ensures durability.

Hyundai Motor and Kia announced that they have tested and reduced the drag coefficient (Cd) by 0.008, improving drag by 2.8%, by installing AAS in Genesis GV60. This is a figure that can expect an additional range improvement of about 6 km.

Hyundai Motor and Kia have applied for related patents in South Korea and the United States, and plan to consider mass production after durability and performance tests.

“This technology is expected to have a greater effect on models such as SUVs where it is difficult to improve aerodynamic performance,” said Sun Hyung Cho, Vice President and Head of Mobility Body Development Group at Hyundai Motor Group. “We will continue to strive to improve the driving performance and stability of electric vehicles through improvements in aerodynamics.”

Hyundai and Kia are also using rear spoilers, active air flaps, wheel air curtains, wheel gap reducers, and separation traps on their vehicles to secure competitive drag coefficients. The Hyundai IONIQ 6 incorporates all of them to achieve a global leading Cd of 0.21, according to Hyundai.

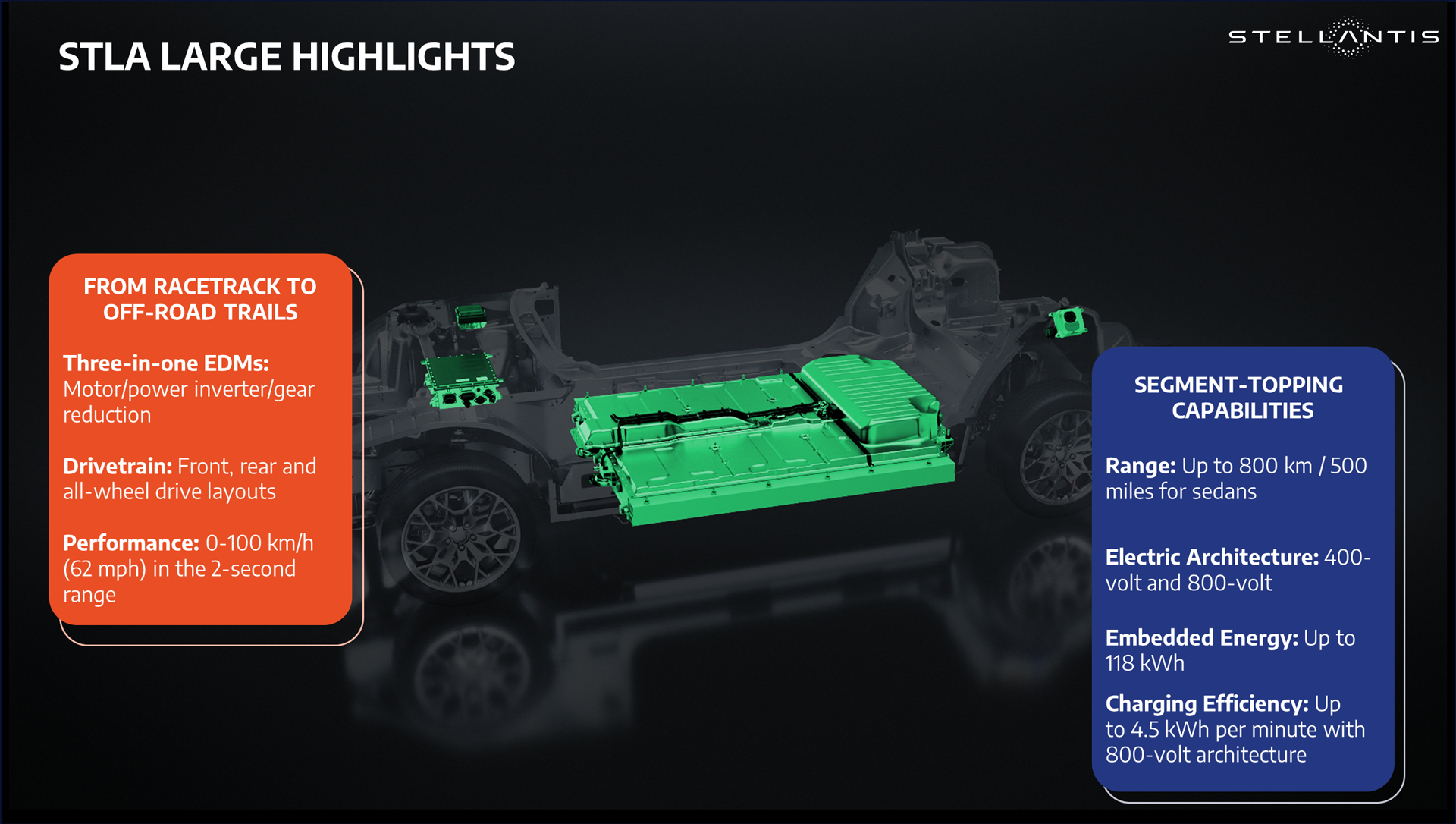

Stellantis has also shared new developments about its battery electric vehicles (BEVs).

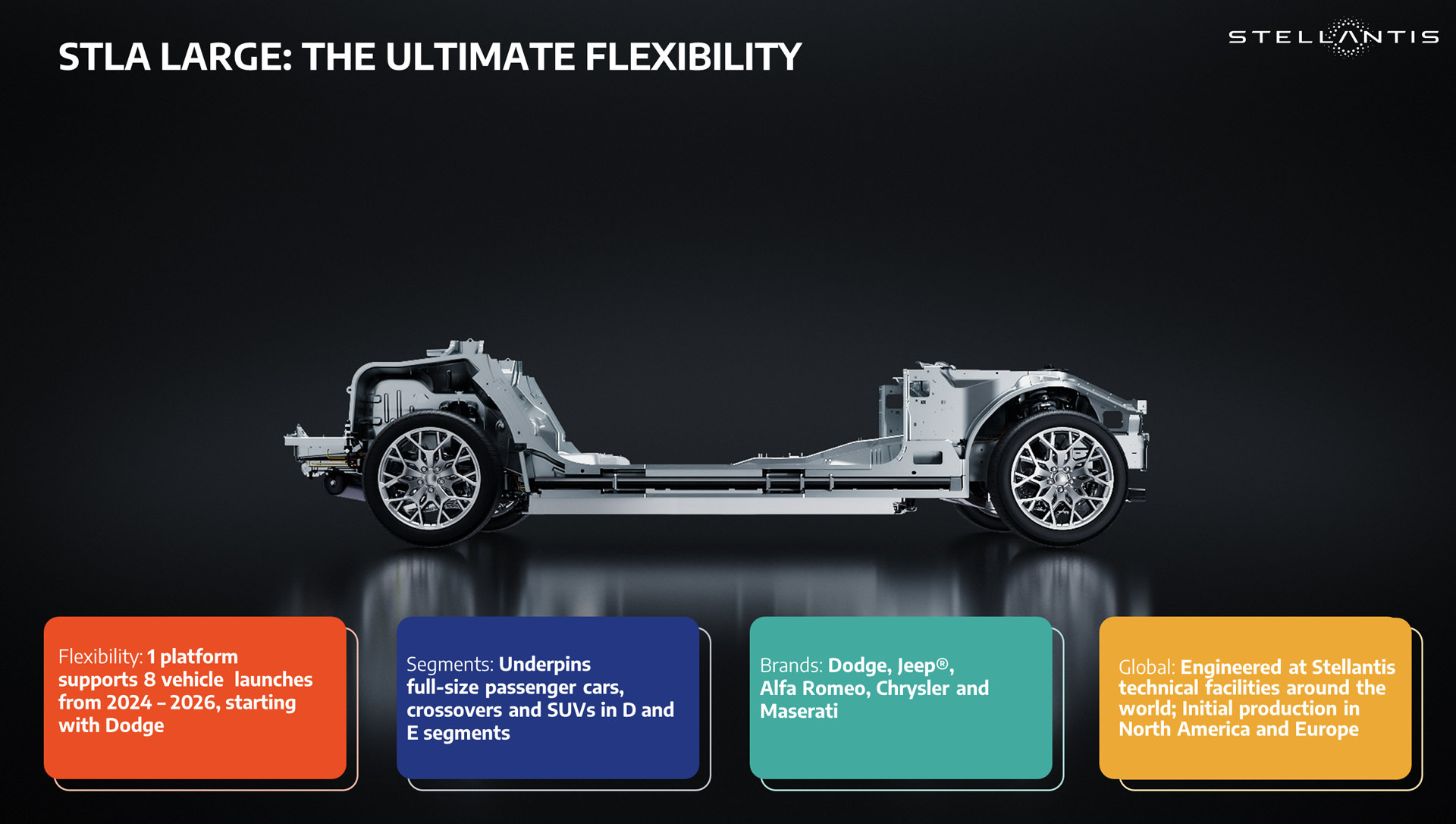

The automaker unveiled STLA Large, its BEV platform, which is the foundation for a wide range of upcoming vehicles, first in North America on Dodge and Jeep vehicles. Eight vehicles will be launched beginning this year through 2026.

The platform enables embedded energy, charging efficiency, high-performance vehicle dynamics, and trail-rated off-road driving, according to Stellantis.

Plans are to use the platform on Alfa Romeo, Chrysler, and Maserati in the future.

“Our goals for our STLA platforms are ambitious but this is what our customers need from us today,” Stellantis CEO Carlos Tavares said. “Creating a family of vehicles from a well-engineered set of components that is flexible enough to cover multiple vehicle types and propulsions, overperforming any of our current products, will address each of our iconic brands’ customers. The flexibility and agility of this platform is its hallmark and will be a driving force for our success in the shift to electrification in North America.”

STLA Large is one of four Stellantis global BEV platforms outlined on EV Day 2021. It’s the second platform to be revealed following the release of STLA Medium in July 2023. STLA Large will be installed in several plants in Europe and North America and available in multi-energy variants, including hybrid and internal combustion.

The platform’s flexibility allows engineers and designers to adjust the wheelbase, ground clearance, and overall length, width, and height, according to Stellantis.

A variety of suspension modules and powertrain cradles can be employed to suit vehicle-specific performance needs including ride, handling, and comfort. Engineers can adjust key dimensions, such as the front spindle to the driver foot, the front and rear overhang, or the passenger compartment floor to fine-tune vehicle capabilities and performance, Stellantis said.

The platform is made of advanced high-strength materials to optimize weight and rigidity, while the cabin heating/cooling system, steering, braking assist, and propulsion are designed to minimize energy consumption to increase driving range to 500 miles for sedans.

Three-in-one electric drive modules (EDMs) incorporate the motor, power inverter, and gear reduction. They can be configured in front-wheel-drive, rear-wheel-drive, and all-wheel-drive layouts. At zero to 62mph in 2 seconds, Stellantis touts STLA Large as having “the potential to carry extreme power that will outperform any of the existing Hellcat V8s.”

Stellantis plans to have 48 BEVs on the market by 2024.

Images

Featured image: Illustration of Hyundai and Kia’s Active Air Skirt (AAS) technology. (Provided by Hyundai and Kia)