EV efficiencies needed to reduce energy usage and costs, report says

By onMarket Trends

The Electric Power Research Institute (EPRI) and Natural Resources Defense Council (NRDC) recently published a report that states electric vehicle (EV) efficiency improvements could reduce future electric infrastructure buildout, energy usage, and consumer costs over the next three decades as the U.S. aims to have net-zero targets by 2050.

The study suggests possible EV efficiencies could include reducing the weight of batteries, reducing aerodynamic drag, improvements to battery and powertrain, and higher battery density. The changes would give owners lower costs and better performance, the report says.

EV efficiencies could reduce electricity consumption per mile by half, lower electricity demand by hundreds of terawatt-hours annually, reduce peak demand by nearly 300 gigawatts, and provide consumers energy cost savings of more than $200 billion annually if changes are made without raising costs, according to the study.

“Transportation energy efficiency gains can provide many benefits to society,” said Rob Chapman, EPRI senior vice president of Energy Delivery and Customer Solutions, in a press release. “This study demonstrates that continued advances in EV efficiency have the potential to substantially reduce physical grid and charger buildout, which could further decrease consumer energy bills and help electric companies keep better pace with accelerating customer demand. Lower cost of vehicle ownership and less need for home charging electrical upgrades can make electric mobility more accessible to all communities.”

The study says energy use has increased by 50% since 1970 and efficiency changes by industries have been essential. For example, the electricity needs for refrigerators dropped by a factor of four since 1975, the report says. Refrigerators cost per cubic foot dropped even as size and service quality increased.

However, the automotive industry faces challenges as it shifts to EV production, the report says. This includes slow production and supply chain movement of raw materials for electric batteries.

Model projections show electricity demand for on-road vehicle charging in 2050 could be as much as 65% of today’s total electricity demand if no efficiencies are made.

Efficiencies outlined in the report seem to be ones OEMs are already attempting to tackle.

Stellantis NV CEO Carlos Tavares told The Detroit News earlier this month that the company believes the weight of EV batteries will have to be cut in half over the next decade to make cars more efficient and environmentally friendly.

“They need a very significant breakthrough in terms of chemistry,” he told the newspaper. “Right now for a decent range, we are using 1,000 pounds, i.e. around 500 additional kilograms, of raw materials to create the battery pack to move the vehicles.”

The company announced plans to lay off about 400 U.S. workers late last month as it shifts its focus to making a more affordable EV.

Earlier this year, Hyundai Motor and Kia unveiled an Active Air Skirt (AAS) technology to reduce aerodynamic resistance when a vehicle is operating at speeds of 49 mph or more, according to a press release.

“In the EV era, competition to secure a better driving range from a single charge has become fierce, making the relationship between vehicles and aerodynamics even more important,” the release says. “Furthermore, aerodynamic performance has a significant impact not only on power performance but also on driving stability and wind noise.”

The technology is installed between the front bumper and the front wheels. It remains hidden during normal operation but operates once certain speeds are reached, the release says.

Hyundai and Kia claim the technology reduces the drag coefficient by 2.8%.

Within recent months, Nissan introduced the Interstar, a large van with a full-electric powertrain, in Europe.

“The model features not only increased size and versatility, ensuring it can be tailored to be as unique as the customers it serves, but it is also Nissan’s first large van available with a 100% electric powertrain without compromise on performance, a Nissan press release says.

The release claims the vehicle can reach the 252 km range in 30 minutes and has a towing capacity of 2500 kg.

Tesla has touted multiple designs to reduce the size of EV batteries are under development by the company in recent years. One design, according to a recent article by carwow.com, is known as the tabless design.

“This technology is essentially a new way of connecting the battery’s cells together, and it reduces the size of the battery by around 35%,” the article says. “ They can also store and release more energy without overheating, giving them as much as 16% more range per kilowatt-hour than traditional batteries.”

In an article earlier this month, The Verge reports Elon Musk plans to use the tabless battery in a compact affordable vehicle he’s planning for 2025. Musk has said the battery will help make the vehicle’s cost similar to that of a combustion engine vehicle.

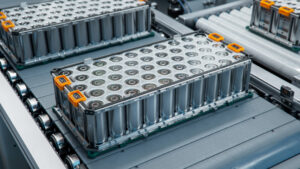

IMAGES

Photo courtesy of SweetBunFactory/iStock