Volvo using AI-generated virtual worlds for safety, GM announces further AI developments

By onMarket Trends | Technology

Volvo Cars can now synthesize incident data collected by the advanced sensors in its new models, such as emergency braking, sharp steering, or manual intervention, to create “even safer” vehicles.

Volvo uses AI-generated life-like virtual worlds to enhance the development of its safety software, and with data collected can, “probe, reconstruct, and explore” to better understand how incidents can be avoided, according to a press release from the OEM.

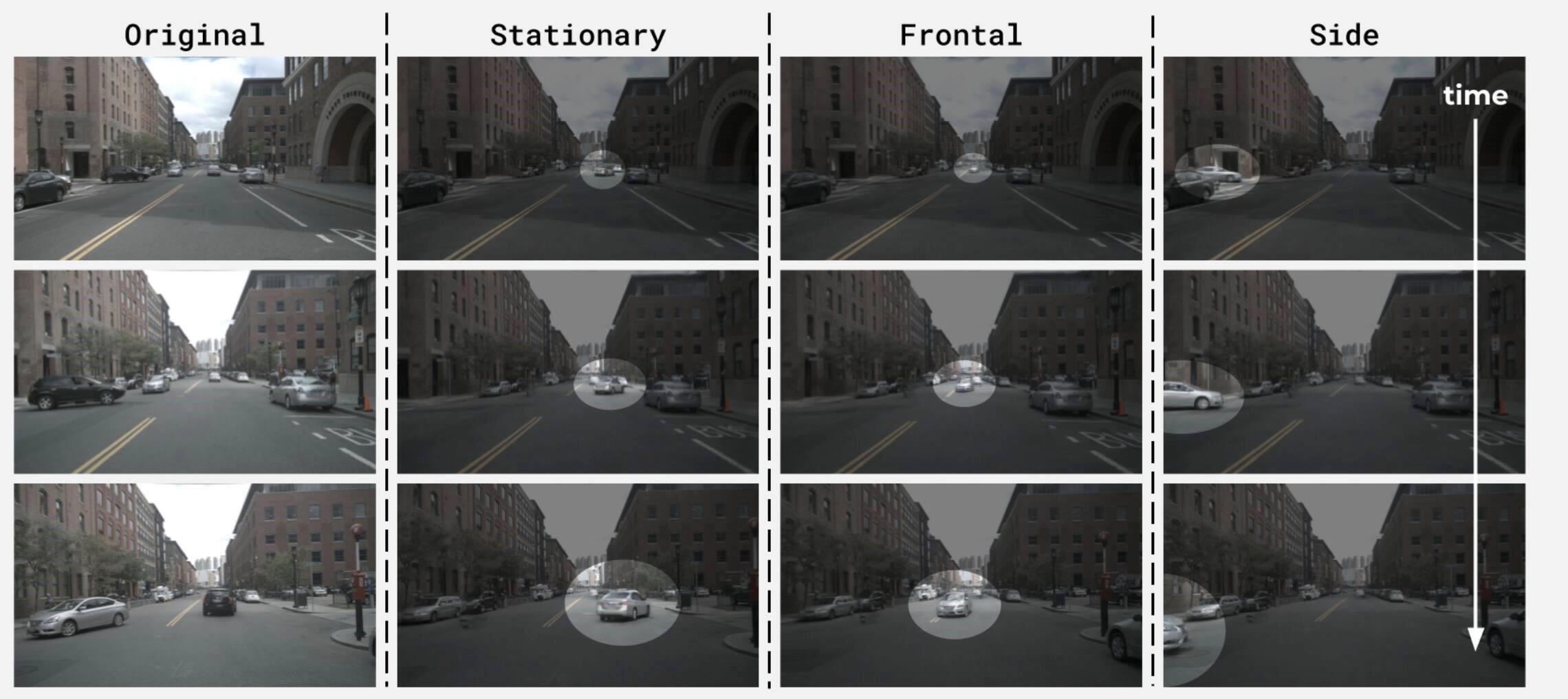

“This is possible thanks to an advanced computational technique called Gaussian splatting, which can create a vast amount of realistic, high-fidelity 3D scenes and subjects from real-world visuals,” the release says. “The virtual environment can, for example, be manipulated by adding or removing road users and changing the behavior of traffic or obstacles on the road to generate different outcomes.”

Volvo says the technique exposes its safety software to all types of traffic situations at a speed and scale not possible before.

“We now can develop software that works well also in complex, rare yet potentially dangerous ‘edge cases’ and reduce the time it takes to expose our software to edge cases, from months to days,” the release states.

Alwin Bakkenes, Volvo Cars head of global software engineering, added, “We already have millions of data points of moments that never happened that we use to develop our software. Thanks to Gaussian splatting we can select one of the rare corner cases and explode it into thousands of new variations of the scenario to train and validate our models against. This has the potential to unlock a scale that we’ve never had before and even to catch edge cases before they happen in the real world.”

Volvo uses virtual environments alongside real-world testing for software training, development, and validation. The virtual environments are developed in-house with Zenseact, an AI and software company founded by Volvo Cars. The project is part of a doctorate program in which Swedish universities explore whether neural rendering techniques will be integrated into future safety initiatives.

Volvo Cars can explore technologies like Gaussian splatting thanks to the recently expanded relationship with NVIDIA.

The new generation of fully electric cars, built on NVIDIA’s Accelerated Compute Platform, collects data from various sensors to understand what’s happening in and around the car better than ever before, according to the release.

“An AI supercomputing platform, powered by NVIDIA DGX systems, contextualizes this data, unlocks new insights, and trains future safety models,” the release says. “It will improve and accelerate the development of artificial intelligence.”

Also this week, GM announced an expanded collaboration with NVIDIA to develop next-generation vehicles, factories, and robotics using AI simulation and accelerated computing.

Dave Richardson, GM’s software and services engineering senior vice president, wrote in a press release that the OEM’s investment in NVIDIA GPU platforms for AI model training will be extended to create digital twins of assembly lines via the NVIDIA Omniverse platform, enabling virtual testing and production simulations to reduce downtime. NVIDIA’s DRIVE AGX will also be used for future in-vehicle ADAS hardware as well as in-cabin enhanced safety driving experiences.

“Additionally, we’re applying AI to robotics platforms for precision welding and material handling and transport, while improving manufacturing efficiency, freeing our workforce to focus on the craftsmanship that customers love about GM vehicles,” Richardson wrote. “In the past, a vehicle’s central control unit, or VCU, was sufficient for basic features like Bluetooth calls or screen navigation. But car buyers now expect more customization and convenience and we’ve reimagined our electrical architecture in response. The integration of vehicle hardware and software will make our cars far more capable and flexible.”

He added it’s well underway in developing a unified and updatable software platform for everything from smaller vehicles to full-size trucks.

“Software will help unlock many new capabilities, as we send regular over-the-air updates, improving the customer experience for vehicles already on the road,” Richardson wrote. “In the future, we expect to launch personal autonomous vehicles, or PAVs, with the ability to take you wherever you want to go without a human driver. As we enhance driver-assistance features and introduce advanced levels of autonomy, a sophisticated electrical architecture with high-performance computing becomes critical.”

Last year, Porsche said it had begun working to create a framework of standards for virtual testing of vehicles as the practice is becoming more common for OEMs.

The company said it was working with Cariad, a Volkswagon software company, and the Association for Standardization of Automation and Measuring Systems (Asam e.V.) to create the standards through a project named Asam Quality Check.

Porsche Engineering created an end-to-end toolchain to generate virtual test tracks from raw data.

Data about environments is accumulated through high-resolution maps or real test drives with Porsche’s Joint User Personalized Integrated Testing and Engineering Resource (JUPITER) vehicles.

Images

Featured image: Illustrative image of Gaussian splat scenarios technique (Provided by Volvo)

Gaussian splat scenarios image (Provided by Volvo)