Porsche working on standards for virtual testing of vehicles

By onAnnouncements | International | Technology

Porsche says it is working with other partners to create a framework of standards for virtual testing of vehicles as the practice is becoming more common for OEMs.

The company is working with Cariad, a Volkswagon software company, and the Association for Standardization of Automation and Measuring Systems (Asam e.V.) to create the standards through a project named Asam Quality Check, says an article, first printed in Porsche Engineering magazine in January and later published online in Porsche’s newsroom.

“Scalable simulation solutions can only exist with standards that are interpreted and implemented uniformly,” said Marius Dupuis, Asam CEO, in the article. “Without standards, the world is indescribable.”

The Porsche Cayenne was test-driven more than 4 million test kilometers before it was available to consumers, according to the article. It says more than 1,000 kilometers were virtually driven for every real-life test kilometer.

“The engineers generate a digital twin of the vehicle and then put it through its paces in virtual test drives in a simulation environment on a synthetic or hybrid test bench (SiL, HiL, ViL) — primarily in situations that rarely occur in real life or are too dangerous to test in real conditions,” the article said. “How does the cruise control react, for example, when there’s a wild boar waiting at the end of a curve?”

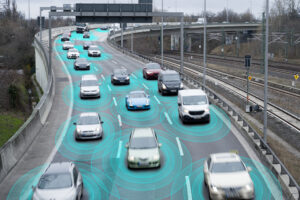

Virtual testing has become “indispensable” for vehicle features such as driver assistance systems and highly automated driving functions, it says, adding that as OEMs move toward automation, billions of test kilometers will have to be driven.

Older manual methods of creating roads and environments for virtual testing have become insufficient, the article says. Porsche Engineering has created its own end-to-end toolchain to generate virtual test tracks from a range of raw data, it says.

Data about environments is accumulated through high-resolution maps or real test drives with Porsche’s Joint User Personalized Integrated Testing and Engineering Resource (JUPITER) vehicles. It says Google Maps isn’t detailed enough.

“We sometimes go down to the millimeter level and need information about lane and road width as well as three-dimensional cross-slopes,” says Tobias Watzl, Porsche Engineering development engineer responsible for track modeling.

A logical model is created from map data, road construction guidelines, and mathematical functions in the first step of creating the track model. Next, a 3D model of the road that can interact with sensor models is generated.

“This virtual test track can be changed in any way required, adding slip roads or infinite circuits,” the article says. “Generic scenes with no real-life counterpart are also adapted to the driving function to be tested. If the objective is an algorithm for traffic sign recognition, for example, numerous different signs are placed along the road.”

Real roads, such as the A8 freeway from Stuttgart to Munich, can be modeled.

“In order to be able to optimize camera-based functions such as lane detection, the virtual track model must look like it does in reality,” the article says. “To do this, it is given a virtual environment. For this purpose, Porsche Engineering has integrated the 3D graphics software Houdini into its pipeline, which is also used in the film industry.”

Virtual test tracks will need to be more extensive and detailed in the future, the article says. For example, it is always summer on current test tracks with the roads clean and dry.

“In the future, a winter variant could be introduced, with piles of snow on the side of the road that cover lane markings,” says Watzl in the article.

Multiple OEMs have made steps to create more accurate simulation testing in the past year.

BMW i Ventures announced in May that it invested Simr, a cloud simulation company. Simr provides a platform for using any compute resources with any simulation tool.

The investment enhances the company’s newly launched Simulation Operations Automation (SimOps) platform, according to a company news release. It says the platform can revolutionize how engineers design, verify, and test products by allowing them to automate simulations in the cloud.

“SimOps has the potential to revolutionize how companies design complex, breakthrough products by letting teams iterate and test their ideas in the time they were previously forced to waste waiting for simulations to be completed,” said Baris Guzel, BMW i Ventures partner, in the release. “SimOps gives engineering teams the power to explore more options faster, and at lower cost. As manufacturing continues to evolve towards more digital and simulation-driven development processes, Simr is well-positioned to play a pivotal role in this transformation.”

Earlier this year, Mercedes-Benz performed the first vehicle manufacturer X-ray of a crash test, which the company has said could be used to help create more accurate digital modeling crash tests in the future.

Last year, the Insurance Institute for Highway Safety (IIHS) developed a virtual test to measure how seat and head restraints protect vehicle occupants.

Marcy Edwards, an IIHS senior research engineer, previously said in an article that digital modeling could one day make it easier to test various risk factors that are difficult to do with real-world crash tests. For example, modeling currently in development could perform a crash test multiple times with different body types.

A 2023 article from The Engineer says modeling can be used to simulate a driver or passenger as a pregnant female, an elderly person, or a child.

“For elderly individuals, who usually have decreased bone strength and increased brittleness, virtual modeling can help understand the impact that the sudden inflation of an airbag would have on them in the event of a collision,” the article says.

It says modeling can replicate injuries to the musculoskeletal systems and organs in ways real-world testing can’t.

A Pennsylvania company is using simulation technology with plans to change the materials OEMs use to make car parts, according to a JustAuto article.

Ansys can use simulations to test materials, such as recycled plastic, early in a part’s design process, the article said.

The company’s simulations use physics models to understand the variability of a material property. The simulations can be replayed hundreds of times to see how the material responds.

“Simulation has become a prerequisite for every engineering business,” said Scott Wilkins, Ansys lead product marketing manager, in the article. “…That’s really our space: how we can translate the laws of physics into something that you can visualize and accomplish digitally. That is our power from a company standpoint.”

Images

Featured image: IGPhotography/iStock