Post-crash inspections uncover chronic air bag deformities

By onRepair Operations

In a recent Autobody News column, Collision Advice President Mike Anderson shared a startling example of what can go wrong when safety inspections aren’t conducted on air bags post-collision.

The example comes from a conversation Anderson had with Tyler Smith, owner of Rick’s Paint and Body, a Lexus-authorized collision center in Augusta, Georgia. Toyota and Lexus recommend post-collision repair inspections on many of their vehicles, Anderson wrote. For example, the Toyota Camry and Lexus ES 350 call for air bag inspections, even in non-deployment crashes.

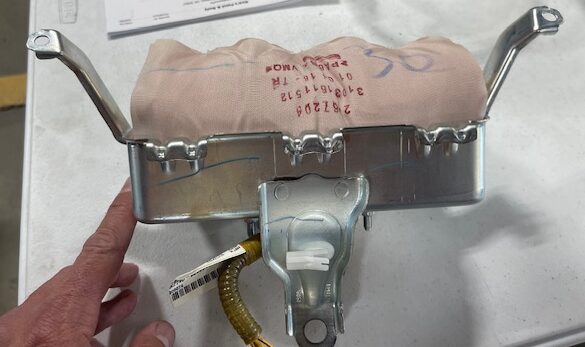

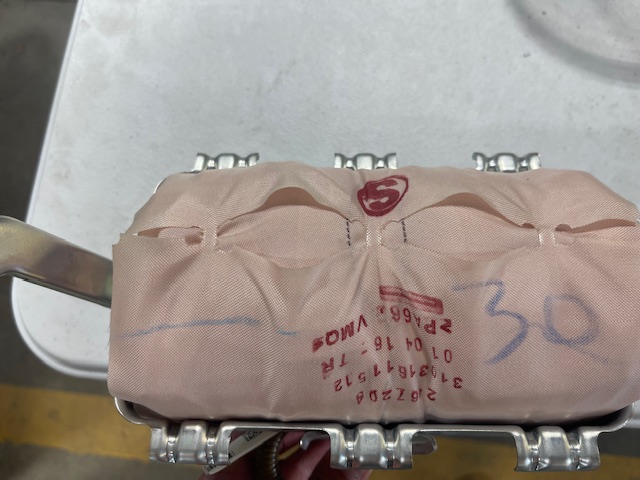

A post-collision safety inspection of a vehicle in Smith’s shop found a bracket that mounts an air bag underneath the dash panel was tweaked.

“It was the passenger head air bag that we found in numerous vehicles have been deformed,” Smith told Anderson, clarifying the shop had found four such instances. “You could see on a couple of them where the brackets where they mount up underneath the dash panel were slightly tweaked, and instead of the air bag being a nice little neat package, the top of it was bulged out almost like a loaf of bread. The webbing that kind of holds it all together was stretching so much that it was starting to separate.”

Had the inspection not been performed, this likely wouldn’t have been found since Smith said none of the vehicles showed related warning lights on the dash or diagnostic trouble codes.

A post-collision safety inspection of a vehicle at Smith’s shop found an undeployed air bag bulging and separating the webbing that held it together.

Smith said he checked the deformed air bags against new replacements to make sure what he was seeing wasn’t how the air bags should look.

The same air bags were used to show local firefighters how air bags deploy. Three didn’t deploy. All of the vehicles were about four to eight years old and took mid-sized hits in their left rear quarter panels.

“So I can’t say for sure, but they might not have fired if we’d left them in the vehicle and it was involved in a subsequent accident,” Smith said.

Anderson added, “Smith said his shop has done quite a few inspections on similar year, make, and model vehicles and not found issues with the majority of those particular air bags, so he doesn’t think it’s an issue from the factory. But in any case, in his mind, that makes doing the inspections to find the ones that are deformed all the more important.”

Smith told Repairer Driven News his shop still finds a few deformed air bags here and there.

“Depending on the insurance company, they don’t want to pay for the post-collision repair procedures hardly at all,” he said. “That is a fight. We show it to them where the manufacturers state that these have to be inspected and they try to weasel their way out of it.

“Once we show the deformity then usually we can get it paid for. There have been significant cases where there was not any deformity and the insurance companies would just refuse to pay for it [post-collision inspection].”

When the inspections aren’t paid for, the shop is “eating an awful lot of labor,” he added.

“That’s just a business decision that we’ve made on our end, case by case, as to whether to pursue it from the customer or not,” Smith said.

Some insurance companies have said they called dealerships to ask if the inspections are necessary and were told they aren’t, so they didn’t want to pay for it, Smith said.

It was recently shared by Nylund’s Collision Center in Colorado that dealerships haven’t been replacing one-time-use pressure sensors.

“What does that mean to you, the consumer? It means either there’s an incredible lack of knowledge out there of what needs to be done to keep you and your family safe on the repair side of things — the shop that you choose to bring it to,” said Rob Grieve, Nylund’s Collision owner, in an April webcast episode. “Or it could be, potentially, insurers saying that’s not necessary because they would look at what we read there [in OEM procedures] and they would say, ‘Well, that’s just a recommendation and we don’t feel like that needs to be done.’ And many shops would say, ‘Oh, OK.’

“Air bags have become more and more complex and the science that is going into them has become rigorous. That system thinks faster, with all the information those monitors are getting, than we can think. That’s why there’s no switch to just hit the button for air bag because you think you need them. The car knows. It’s important, to you — a consumer — that you’re taking it to someplace that will do the research necessary.”

OEM procedures stating it’s recommended versus required have been used to justify non-payment, according to Smith.

“In a lot of the Asian vehicles, the language is recommended,” he said. “When it says recommended, the insurance companies are taking the stance of, ‘Oh, they recommend it but it’s not required so we’re not going to pay for it.'”

Anderson has urged the collision repair industry in many of his presentations to always check OEM procedures on every repair and to always conduct safety inspections.

“Ladies and gentlemen, those deformed air bags found during safety inspections by Smith’s team should be all you need to understand you are playing a dangerous game with your customers’ lives and your shop’s liability when you don’t follow the safety inspections procedures laid out by the automakers,” Anderson wrote in his column.

In this video from the 2022 Society of Collision Repair Specialists (SCRS) IDEAS Collide Showcase, Anderson shares a personal story of why he advocates for safety inspections:

Anderson, Database Enhancement Gateway (DEG) Administrator Danny Gredinberg, and Bruce Halcro, former chairman of the SCRS Board, share details here on a “friction point” in the industry — insurance companies refusing to pay for safety inspections:

Images

Featured image credit: zorazhuang/iStock