Autobody News webinar addresses OEM repair procedures, vehicle complexity, and repair implications

By onBusiness Practices | Collision Repair | Repair Operations

Times have changed in how collision repairs are completed, and rapidly with emerging technologies adding up to more than 100 million lines of code within any given vehicle, making it even more important to always consult and follow OEM repair procedures.

That was the topic, along with other mindful business practice tips, that Erin Solis, Square One Systems operations senior vice president, and Liz Stein, Certified Collision Group strategic initiatives vice president, shared during an Autobody News webinar on Wednesday.

“You don’t just have to know what all of the technology does on this one brand of car,” Solis said. “You have to know what all the technology does on all of the brands of cars. And even if you’re looking at one brand of car, you may have different submodels and whatnot that changes what options the vehicle has. You could have two of the same vehicles sitting next to each other that have totally different options. It’s a lot to try to keep up with.”

Stein agreed and noted that shops should always take advantage of all training options.

“Everybody that’s touching that vehicle is taking those training classes and understanding those training classes,” Solis added. “If you’re at a shop and you’ve got five blueprinters, you may be required by a specific OE for only one person to take a training, but is that the only person that is going to be blueprinting that car? It’s important that everybody has all of the information and not just one person.”

If only one person can be sent to off-site, in-person training for cost and/or operations reasons, Solis suggested when that employee comes back to share what they’ve learned with their team to ensure everybody has “all of the latest and greatest information access to the OEM repair data and everything that they need to do to diagnose and properly repair the vehicle.”

During the webinar, Solis and Stein discussed the “repair reality gap” between the complexities and costs of shops carrying out OEM repair procedures and educating insurers and customers on their importance.

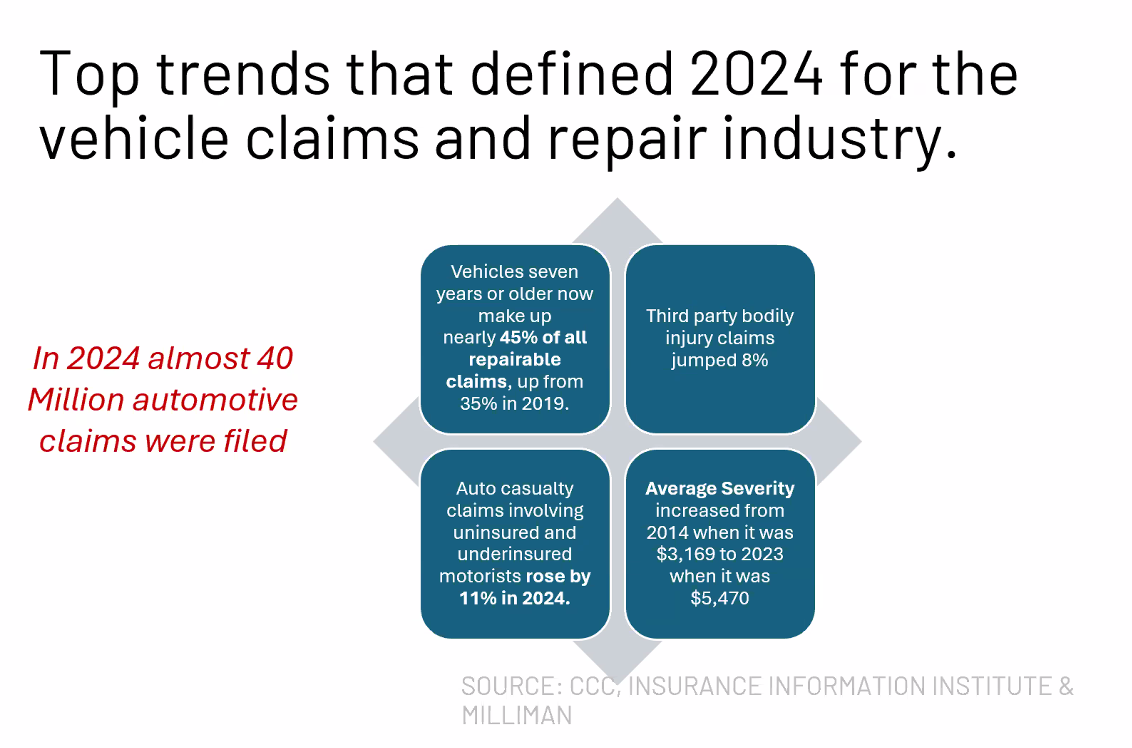

While many are talking about claims volume going down, Solis noted that the industry is still seeing large increases in severity and claims frequencies.

Solis and Stein compared vehicle collision repair to healthcare, in that insurance is part of the equation in both industries, with different coverages and policies that might differ from what the doctor, or in this case, OEMs and technicians, recommend.

So, Stein said, the question is, how do we bridge that gap?

She cited a 2023 study from McKinsey and Co. that found the healthcare industry is confronting the evolving demands and expectations of consumers, mirroring the experiences consumers are used to in engaging with other sectors.

“The perception of choice, that’s where I think as an industry we could really glean, is that the consumer feeling like they’re in the driver’s seat,” Stein said. “I’ve seen it on both sides where the consumer is just kind of forced down a path that they’re like, ‘Well, I didn’t even know what my options were or what’s going on.'”

In a recent experience of her own, when her daughter was involved in a collision, Stein said it was helpful to her, even having been in the industry for years, for the shop to walk her through her options and what was important.

“My kid’s driving this car, I wanted the best option, and I was willing to do it out of pocket,” she said. “You have to make sure that you’re fixing the car right. It can’t be about the money. I think that most of us are going to agree with that.

“If you actually take the time to sit down with the customer and say, ‘These are the things that need to be done, here’s why. Here’s some other options. I may not be willing to do those options, but I want you to know that when you go out and you get other repair estimates, no matter who it’s from, you need to understand these are the differences.'”

Solis added that it’s important for everyone who works in the shop to know the business’s “yeses and nos,” repairs that are acceptable and that aren’t.

“There is psychology in consumer choice,” she said. “For instance, a pack of cigarettes has a warning label that it could cause cancer, but it’s still available if you want to smoke. …Too many times, we don’t really explain, ‘Here are those options.’ It doesn’t mean that you’re going to be willing to do all of those options… I think that’s fair to understand, so that everybody’s on the same page.”

Demographics also play a part, wherein some areas may be more impoverished and in need of financing options, Stein said. They agreed that education on why OEM repair procedures are followed is important, regardless of whether the customer continues with the repair plan or not.

“It goes back to the consumer feels that power of choice, and they feel like they’re in the driver’s seat,” she said. “That’s where I see a lot of consumers, when I look at online reviews, where the frustration is. They feel like that power was taken out of their hands.”

Another tip Solis provided was building adjuster relationships by taking the time to explain and show them why certain tools, equipment, or procedures are necessary. There are also classes offered within the industry that teach how to negotiate with adjusters, she said.

“If you take the time and the care — whether it’s your consumer or an adjuster or another estimator, another technician, your receptionist — it doesn’t matter if you take that time and care with people, you build a relationship and you build a foundation of trust,” she said. “If somebody walks into your facility and right off the bat you’re like, ‘This is what we’re doing, and you’re going to pay for this or you’re going to get out,’ that doesn’t build a strong foundation.”

Stein added that precise documentation is also key.

“Time is our most valuable asset, so making sure that we’re very strategic with what we’re talking about and with photos… that I really need so that I can help with that dialogue,” she said.

Give adjusters the high-level information using line notes provide explanations rather than flooding them with 50 pages of technical information, Solis added.

“If they need additional explanation, then you can walk them through that further, where to find it in those 30 to 50 pages, or whatever, you sent over,” she said.

Stein and Solis said it’s also important to build relationships with OEMs to ask questions about procedures, and local OEM dealerships for business to be sent from shop to shop and from shop to sales to replace total losses. Plus, dealerships can give collision repairers a look at new models of vehicles before they’re wrecked and come to the repair floor.

Working out a way to consistently conduct quality checks of repair processes from keys to keys can also build trust with customers, adjusters, and the shop.

“The staff is empowered, and it’s a coachable moment,” Stein said. “You can do those kinds of checks throughout the process to make sure that what you’re delivering is what you said that you were going to deliver.”

Images

Featured image credit: skynesher/iStock

Slides provided during webinar