3M engineering stresses ‘obvious need’ to follow OEM repair procedures

By onCollision Repair | Repair Operations

A 3M webinar hosted on Tuesday by ASE drove home the importance of following OEM repair procedures, not only for the safety of future vehicle passengers, but also to avoid shop liability concerns and drive up profitability.

“Body shops’ reputation’s on the line, customer safety’s on the line when they get their vehicle back, and the OEM’s brand is on the line,” said Branden Loesch, 3M AOEM application engineering advanced specialist.

While the number of collision repairers looking up OEM repair procedures is increasing, Loesch said there is still “an obvious need to drive increased awareness and understanding of the importance to follow those repair procedures and complete safe and proper repairs.”

“We think following OEM repair procedures and really leaning into doing things the right way is going to help drive additional demand,” he said. “It’s going to improve your repair plan and your estimation, and ultimately, it’s going to help you get paid for those materials you used to complete the repair. All those things should have a positive impact on your profitability.”

Following procedures are also ever more essential as the complexity of vehicles increases, in part due to more mixed materials, Loesch added.

“You have aluminum, steels, magnesiums, some composites — all these unique materials coming together to create today’s vehicles, so it creates complexity in terms of repairability, fastening, joining,” he said. “And then we have the increased complexity that comes along with ADAS — more cameras, more collision avoidance systems on these vehicles than ever.

“I personally don’t know how you fix one of these vehicles without looking up the repair procedures and understanding where do I need to cut? Where does the OEM want me to glue and put the rivets back together? How do I seam seal? Where do I do it, and how do I protect this repair from a corrosion perspective so that it has longevity on the road? Do things the right way so that when I put it back together, the sensors are going to perform, the crashworthiness is going to be restored.”

In reference to concerns in the industry about access to OEM repair procedures, Loesch said he sees it as not so much a challenge of where to find the information as much as it is a challenge to create the time to do so.

“The procedures are up to date, they’re readily made available through the OEM sites,” he said. “Again, that does come at a cost to repairers. But I think the OEMs do a really nice job of making things affordable, giving us options to buy an annual license, a monthly license, or even a one- or three-day license on some occasions, so I can get the information I need to fix that vehicle.”

“Getting that information to the estimation team, to the front office, allows me to build a quality repair plan, and then I can execute and repair to that plan, driving again, quality repairs and integrity of a repair, and hopefully a more profitable repair for that body shop.”

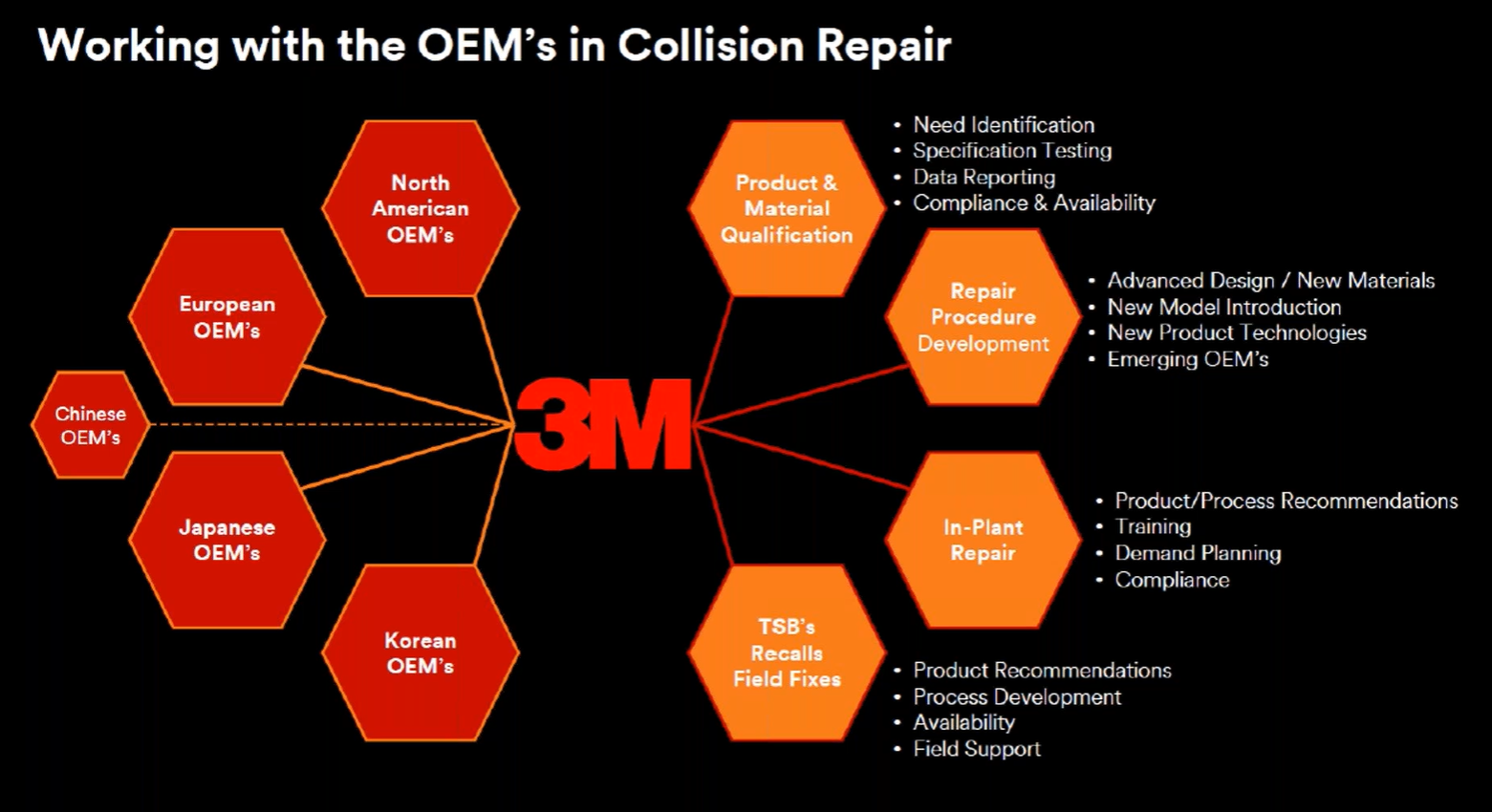

Loesch noted that 3M engineers, key account managers, and business leaders work with OEMs across North America, Europe, China, Japan, Korea, and other areas on product material qualification. For example, a proposed change from a panel bonding adhesive to a structural adhesive in vehicle structure repair.

“We’re going to work with them to identify the right solution, complete the specification testing, make sure we do the data reporting, get their agreement, and drive product compliance and availability globally,” he said. “We’re also working on repair procedure development… from a product and process perspective.”

Loesch added that, in the collision repair space, OEMs most commonly recommend 3M adhesives, coatings, seam sealers, and foams.

“You want to make sure you’re looking up those repair procedures on a daily basis,” he said. “Every vehicle that comes through your shop, you should be checking those repair procedures to make sure you’re following the correct process, that there haven’t been any changes in sectioning or weld locations or the rivets that they recommend being used.

“As we look at product approvals, we always say beware of general claims and generic claims like ‘OEM-approved.’ …You’ll see products out there that say OEM approved, and they very well are OEM approved, but it might only be in a specific couple of unique situations. OEMs typically don’t universally approve product usage across all their repair procedures.”

Caution should also be taken when determining product equivalency because products vary by chemistry, strength, and many other factors, he said.

“I personally work with a lot of chemists and material scientists internally here. We would have a hard time making a product equivalency claim without getting the OEM involved, so leave it up to the OEM as the expert on what should be used to repair their vehicles,” Loesch said.

“The OEM, they’re the authority; they make the vehicle. They have the collision service engineering teams that build these repair procedures that we’re working with to do the qualifications and the extensive testing that goes into those qualifications required to make a safe and quality repair. There’s just too much at stake in collision repair today to deviate from those recommendations and product recommendations you see in the repair procedures.”

He also noted that repair procedures vary between models, even of the same brand; for example, the Honda Odyssey and the Civic.

“One of them is going to recommend an 8115 panel bond, and the other one’s going to recommend a structural adhesive when you’re replacing the roof on their vehicle, so just take caution,” Loesch said. “Make sure you’re looking up that information and don’t just assume because you fixed another Honda vehicle that you should be using the same product on a different model vehicle or any other OEM… Be aware of claims or product equivalents to 3M product callouts by an OEM.

According to Loesch, 3M recommends visiting vehicle OEM collision repair websites directly for the most accurate and up-to-date information, as changes can be made often. He also recommended OEM1Stop and I-CAR’s Repairability Technical Support (RTS) Portal as secondary sites to find information and links to OEM repair information and position statements.

Images

Featured logo provided by 3M

Chart courtesy of 3M presentation given on May 20, 2025/Screenshot