VECO IDs serious, moderate auto body shop red flags

By onBusiness Practices | Education | Legal | Market Trends | Repair Operations

Vehicle Collision Experts CEO Mark Olson last month offered collision repairers 15 warning signs that their shop might be compromising vehicle quality.

Seven of the items listed in his Aug. 10 NACE presentation slides were classified as “Big Rocks.”

“These will put you out of business,” Olson said.

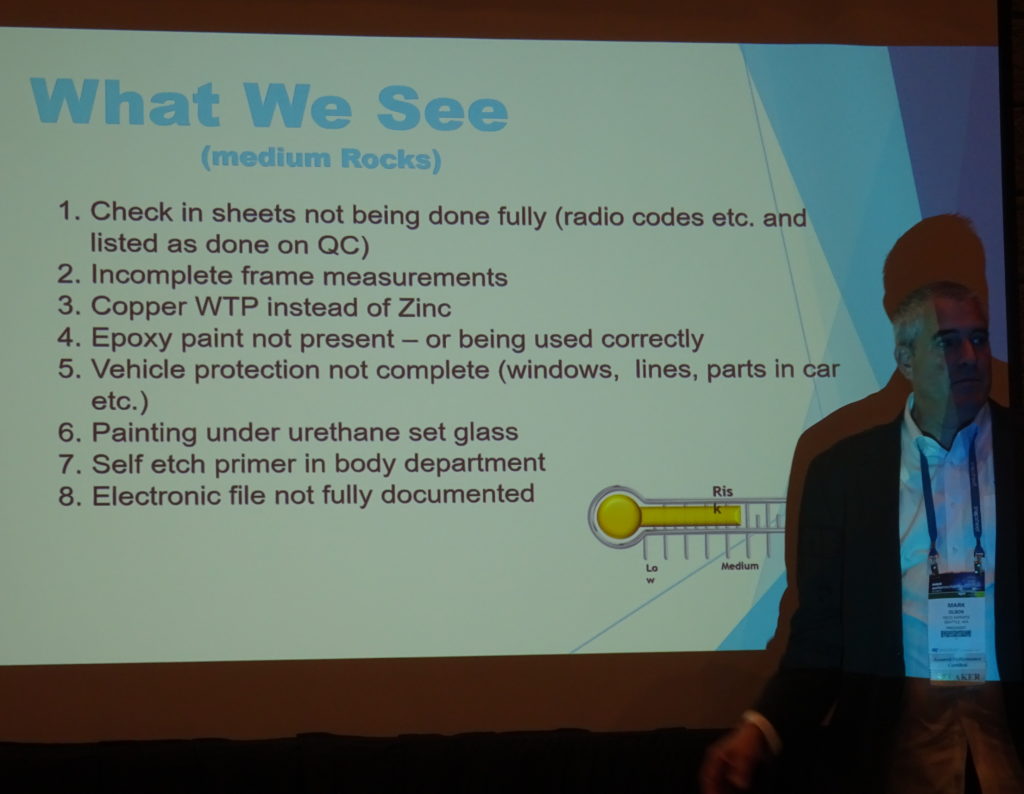

The other eight were considered “medium Rocks,” according to the presentation.

A repairer could look for all 15 at their shop and conclude, “‘Oh my gosh — we’re exposed,'” he said.

Big red flags

1. “Not using QC Sheet/Process as designed”: “That’s 99 percent of the shops,” said Olson, who recommended quality control checklists be completed in full and not merely checked off by a cursory pencil slash.

2. “200 amp welders not being used when appropriate”: A shop might instead use a 140-amp welder instead. The ensuing weld looks fine — “’till the next collision,” Olson said.

Worse, many shops have the 200 welder but don’t use it because it’s more difficult, according to Olson. In California, that’s a Bureau of Automotive Repair violation for “gross negligence,” he said.

3. “Not reviewing OEM procedures and following”: This one is pretty self-explanatory if you’ve been reading our coverage or if you followed the outcome of the John Eagle Collision case.

4. “Cavity Wax not being used enough”: Olson said shops should be consuming one can of cavity wax per technician per week. A check of how many cans were purchased in the past 30 days would give a shop an idea of how many of their customers’ vehicles would rust.

5. “Weld tests not being done prior to welding and documented”: While it was “better than nothing,” a welder telling you a weld is acceptable was not the same as a destructive weld test, Olson said.

Bill Montville of Pro Spot distributor Collision Correction Equipment agreed. The computer merely was checking to see if the necessary amperage was delivered, he said.

That didn’t mean the weld would hold, according to Olson. The correct amperage applied through a mushroomed tip would produce a weaker weld, he said.

“Do not trust that computer,” he said.

6. “Equipment not maintained or inoperable.”

7. “Welder tips on STRSW not dressed and no new in shop”: Read more coverage of this issue here.

Medium red flags

1. “Check in sheets not being done fully (radio codes etc. and listed as done on QC)”: Read more about this here.

2. “Incomplete frame measurements.”

3. “Copper WTP instead of Zinc”: Olson said they called copper weld-through primer “‘contraband.'” No OEMs recommend it, he said.

“It does not belong in collision repair,” he said. (Even zinc weld-through primer — or any weld-through primer at all — could be an issue, depending on the OEM. You’ve got to check.)

4. “Epoxy paint not present – or being used correctly”: A shop might have it, but the painter might not know how to use it right, according to Olson.

5. “Vehicle protection not complete (windows, lines, parts in car etc.)”: If a customer goes to retrieve sunglasses from a car and it’s full of parts, the vehicle will never be right “mentally,” according to Olson.

6. “Painting under urethane set glass”: Olson said that he noticed this issue with the 2010 Honda Fit in the John Eagle Collision case and mentioned it to plaintiff’s attorney Todd Tracy. Tracy had noticed this as well, but opted for the roof because it was easier to pitch to a jury, according to Olson.

“He had two ways to go,” Olson said.

7. “Self etch primer in body department”: How many shops have it there? “Almost every one,” according to Olson. Yet while it does play a role in the paint department, it doesn’t belong on the body side, he said.

8. “Electronic file not fully documented.”

Images:

Vehicle Collision Experts CEO Mark Olson last month offered collision repairers 15 warning signs that their shop might be compromising vehicle quality. (GeorgePeters/iStock)

Vehicle Collision Experts CEO Mark Olson last month offered collision repairers 15 warning signs that their shop might be compromising vehicle quality. On the screen here are the eight “medium” issues. (John Huetter/Repairer Driven News)