Want to fix a Cadillac CT6? Here’s what you’ll need

By onAnnouncements | Business Practices | Education | Repair Operations | Technology

Cadillac has released its list of requirements for independent and dealership auto body shops who want to join its certified CT6 repair network.

Joining will likely require some spending up-front in tools and training — as well as a $4,500 annual fee and initial joining fee — but the car’s advanced, mixed-material body will be different than anything Cadillac’s ever done before.

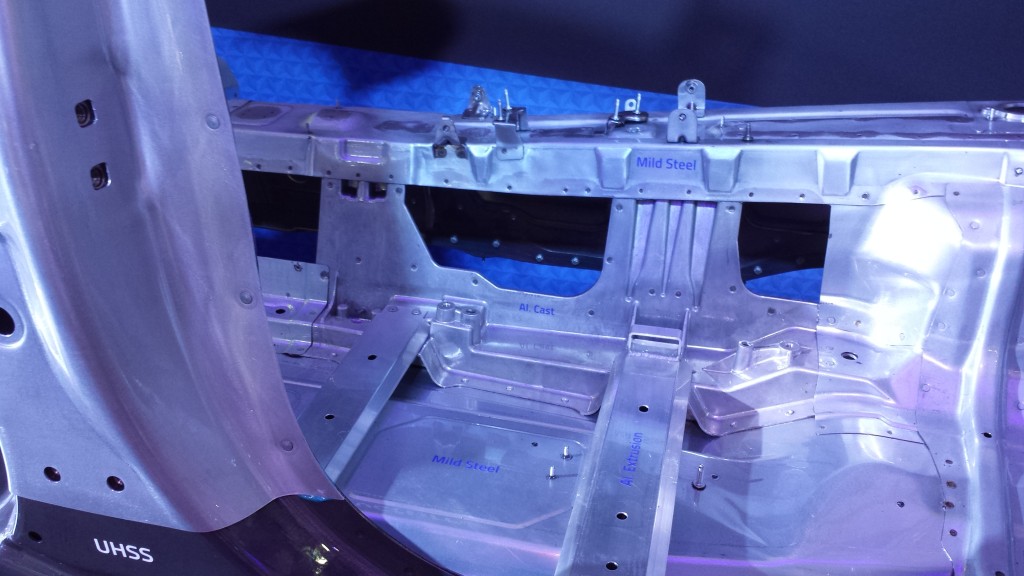

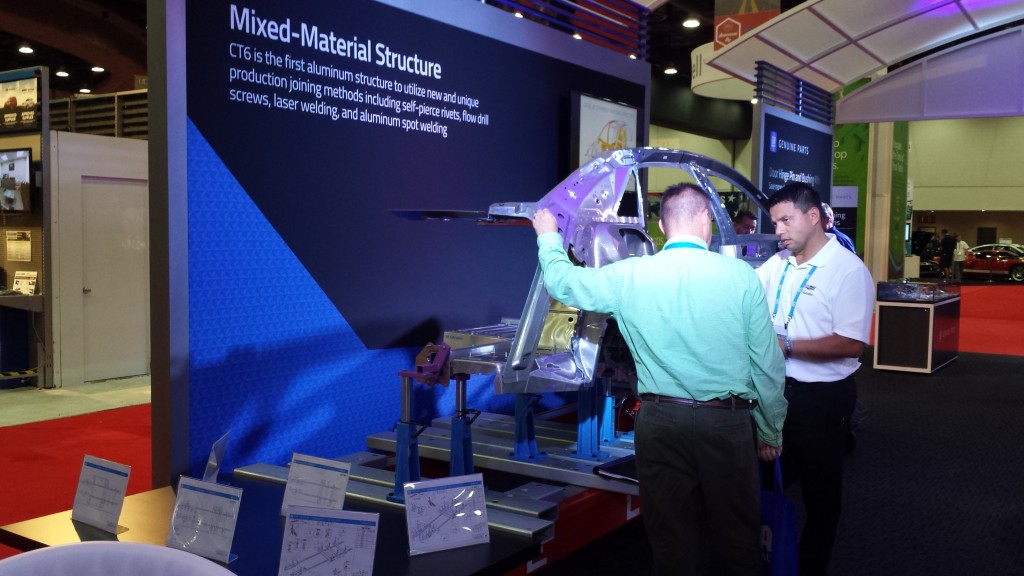

The CT6 is mostly aluminum, but there’s also steels from mild to ultra-high-strength (and other materials).

That mix requires very specific repair techniques to avoid corrosion in addition to the individual demands of aluminum and ultra-high-strength steel repair. Even shops uninterested in joining the network should keep an eye on the CT6 — technology on luxury cars has lately been creeping further and further into the mainstream.

Enrollment is underway and open to non-GM dealerships as well as independent shops. Sign up before Dec. 31 (The CT6 is expected in March), and GM will cut you a break on the second-year fee. Call Axalta at 1-844-545-6107 or e-mail cadillacnetwork@axaltacs.com. Other details are available latest GM Repair Insights and on the Genuine GM Parts website.

This summer, GM estimated the network would have roughly 100 locations nationwide — and these could mostly be independent facilities.

Indies won’t need a dealership sponsor — just be good at what you do and fulfill GM’s program requirements.

Here’s some of the highlights of those requirements, available on a new section of the GM Genuine Parts site:

Tools and equipment

Cadillac tried to compile a tools and equipment list based on specifications rather than brands, but there are some cases where you’ll have to buy a tool from solely one manufacturer or another. (More could be added eventually — joining experts said at SEMA that OEM approval of repair tools is a long and exhaustive process given the stakes.)

For the most part, GM does keep things spec-based. Examples of manufacturers’ offerings which will meet those demands are provided, which should help repairers visualize the gear, but GM notes they’re merely examples. Get the full tool list and examples here.

Aluminum MIG welder: It must be dedicated to aluminum repairs, have a 220-volt/pulse MIG and at least 140 amps, and be able to use .035-5554 wire. If it meets those requirements, you should be good. Cadillac indicated, however, that you would primarily use other joining techniques (rivets, adhesive, etc.) on the CT6, so be careful not to weld the car where you’re not supposed to.

Structural riveting: Yes, you’ll need another rivet gun. Shops will be required to have the Weilander+Schill Express 800 with an accessory kit for the CT6. But on the plus side, it’s been described as the “Cadillac of rivet guns,” and its modular style has been touted as able to gain numerous OEM approvals.

Recommended: The above tools are all needed. But GM also recommends a flow-drill screw hole locator kit. You’ll reuse the existing CT6 flow-drill-screws.

Aluminum isolation: You don’t need a “clean room” necessarily — curtains aren’t out of the question — but you must keep particles isolated within your aluminum repair bay. It must be at least 25 feet long, 10 feet wide, and 10 feet high — probably to hedge your bets against cross-contamination.

Aluminum dust extractor: It must be wet-mix.

Aluminum dents: Whatever you use for aluminum dents must also be wet-mix.

Structural repair bench: GM goes brand-specific here with the fixture-type benches it demands, but at least there are a few options. Get a Celette Sevenne XL or Griffon XL with Fixture Set 2646 and base/piston set (GM notes that North American repairers can obtain a rental fixture set) a Car-O-Liner with EVO 1-3, or a Chief or Spanesi with dedicated CT6 fixtures.

Training and performance

GM wrote in a news release Wednesday that the specific training for the high-strength-steel and aluminum vehicle will be “primarily web based” and offered through a GM-I-CAR partnership. These include 22046. 20W1 “GM Body Structural Fastening Systems 1” and 22046. 20W2 “GM Body Structural Fastening Systems 2,” according to the Cadillac Aluminum Repair Network manual.

Other I-CAR aluminum courses might also be necessary if staff hasn’t taken them yet.

The shop also must have been I-CAR Gold or VeriFacts VQ, had I-CAR tech training certificates, estimator training certificates and be current on aluminum structural certification, according to the shop participation agreement.

Cadillac doesn’t say how many technicians must be trained in aluminum collision repair.

“Each participating shop will be expected to have the necessary number and type of technicians properly trained for aluminum collision repairs,” GM states in the agreement. “It is at Cadillac’s sole discretion to determine the training requirements acceptable for program criteria.

Audits and administration

GM has tapped Axalta to manage the program, and VeriFacts will help manage the network as well as audit shops yearly. Get a comprehensive look at what they’ll look for in the Cadillac Aluminum Repair Network manual.

“Shops will be audited on repair processes and following of repair procedures so it is not just tools and training,” Wheeler wrote.

In addition to checking your facility, gear, and training documentation, shops must prove they know what they’re doing regarding aluminum collision repair in terms of repair planning, vehicle measurement and preservation, structural and cosmetic work and post-repair “cleanup and predelivery.”

The shop manual describes grilling staff or checking actual vehicles to verify “output competency.”

“Ideally, three to four vehicles will be assessed against each of the areas described in output competency repair verification,” the manual states. “If actual vehicles are not available, the auditors will discuss the processes to validate understanding. Should the collision facility fail the audit in an area that is repair-safety related, they may be required to have a second audit to ensure any deficiencies identified in the gap report were addressed.”

If you’re out of compliance and don’t work to regain that compliance, GM will kick you out of the program. If a shop requires a second audit besides the annual one, you’ll have to pay another $1,250.

There’s a lot of great information on the Genuine GM Parts site about the Cadillac Aluminum Repair Network, particularly the manual for shops (There’s a FAQ and a flowchart for joining the network, too.). Check it out and decide if it’s right for you.

More information:

Cadillac Aluminum Repair Network Body Shop Participation Agreement

Cadillac Aluminum Repair Network Program Manual

Cadillac CT6 Collision Repair Tools and Equipment List

Cadillac, December 2015

More information:

Part of the Cadillac CT6 body is shown at NACE in July 2015. (John Huetter/Repairer Driven News)

Cadillac global design executive director Andrew Smith shows the Cadillac CT6 on March 31 before the New York International Auto Show. (Mike Appleton for Cadillac/© General Motors)

Cadillac President Johan de Nysschen promotes Cadillac CT6 April 1 at the New York International Auto Show (Mike Appleton for Cadillac/© General Motors)