Honda releases auto body shop guide to OK’d seam sealers, adhesives, other materials

By onAnnouncements | Education | Repair Operations | Technology

Honda on Friday made life easier for collision repair facility owners and purchasing personnel with service bulletins listing all OEM-approved products in many materials categories.

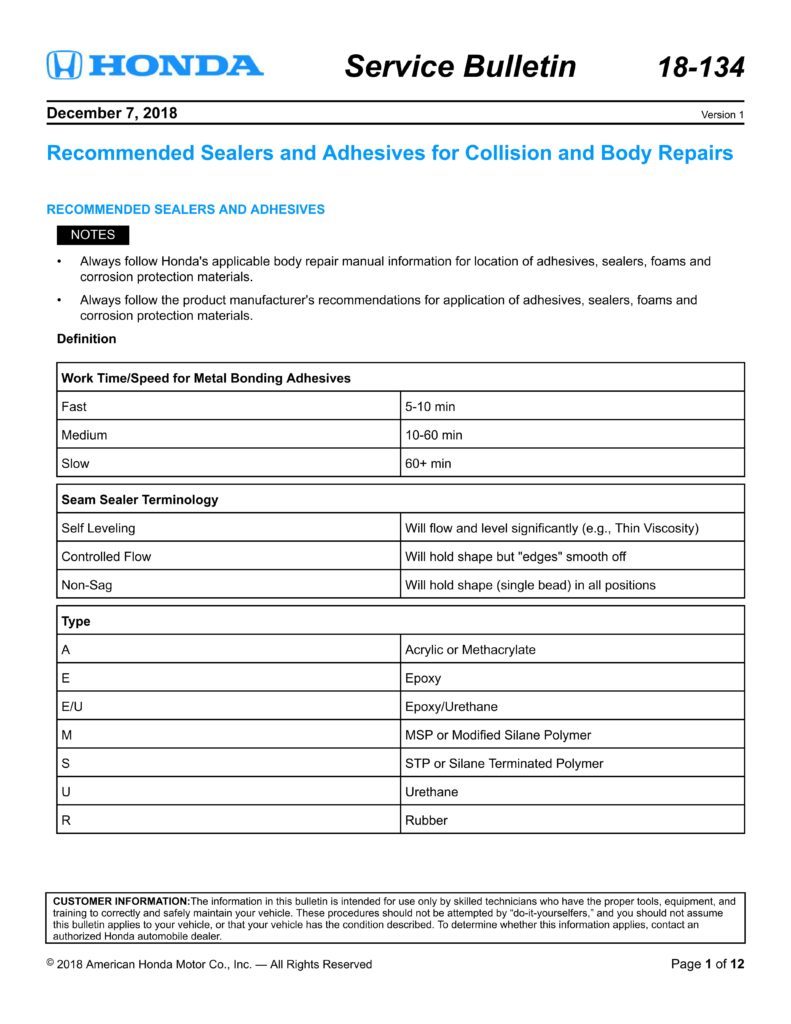

The charts of recommended Honda and Acura sealers and adhesives include associated products like weld-through primer, sound deadening, and even which cavity wax kits get the OEM’s blessing.

“In Honda and Acura body repair information we will commonly call out one product for adhesives and say to use this or equivalent,” Honda collision marketing national assistant manager Scott Kaboos wrote in an email. “This list should be seen as what American Honda recommends as ‘Equivalent’. As far as seam sealers, we do not call out any particular products at this time in the body repair manual and it will be up to a shop to match a product in this recommended list that most closely represents the product installed by the manufacturer. Prior to this document there was no guidance from American Honda on sealers.”

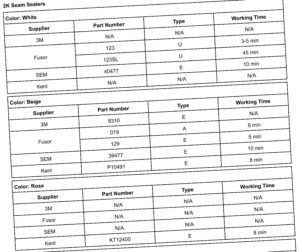

Honda provides the manufacturer’s name, the part number for the substance or item, and codes with relevant chemical details. (For example, “Epoxy,” “Rubber,” or “Acrylic or Methacrylate.”) You’ll even find lists of certain approved seam sealers categorized by colors ranging from black to rose.

The OEM also threw the technicians using the products on the floor a couple of bones.

Repairers can understand what some sealers will do when dispensed thanks to Honda classifying them with terms like “Controlled Flow,” defined as “Will hold shape but ‘edges’ smooth off.” Honda also offered working times for some of the substances, which ought to help techs and production managers understand the level of urgency needed for certain operations.

“Work time is the amount of time the material can be dispensed and tooled before it begins to cure and can no longer be manipulated,” Honda collision marketing national assistant manager Scott Kaboos wrote in an email. “For example, when using an adhesive with a 60 minute work time, the material would need to be applies, spread out and the panels firmly attached and held in place before the end of the 60 minute work time. There would then be addition time needed before painting and complete curing to occur.”

Finally, repair professionals will also appreciate a nod to their professionalism contained in a warning to Honda owners.

“The information in this bulletin is intended for use only by skilled technicians who have the proper tools, equipment, and training to correctly and safely maintain your vehicle,” Honda wrote in a message echoed on the Acura version of the bulletin. “These procedures should not be attempted by ‘do-it-yourselfers,’ and you should not assume this bulletin applies to your vehicle, or that your vehicle has the condition described. To determine whether this information applies, contact an authorized Honda automobile dealer.”

The Honda and Acura charts can be found in the free part of Honda’s OEM repair procedure website Service Express. However, repairers will need to use the paid Honda instructions and materials manufacturer information to do a correct repair.

“Always follow Honda’s applicable body repair manual information for location of adhesives, sealers, foams and corrosion protection materials,” Honda wrote.

“… Always follow the product manufacturer’s recommendations for application of adhesives, sealers, foams and corrosion protection materials.”

One can’t assume the information on this list will stand for all time — approved products and their individual specifications can change — or never be supplemented or overridden by Honda repair procedures. So don’t just print out the document and never look back. A shop’s best bet will be to look up the Honda and Acura repair procedures and this document online anew on every vehicle to ensure the most current version of the files.

In other seam sealer news, Honda and Acura in a September Body Repair News reported that the L&L Products L-0504 (P/N: 08712-0011) two-part epoxy adhesive mentioned in some repair procedures was unavailable. It directed shops to use 3M 07333 impact-resistant structural adhesive as a substitute.

More information:

“Recommended Sealers and Adhesives for Collision and Body Repairs”

Honda, Dec. 7, 2018

“Recommended Sealers and Adhesives for Collision and Body Repairs”

Acura, Dec. 7, 2018

“Structural Adhesive for Body Component Replacement”

Honda, September 2018

“Structural Adhesive for Body Component Replacement”

Honda, September 2018

Honda repair procedures website

Images:

Honda on Dec. 7, 2018, made life easier for collision repair facility owners and purchasing personnel with service bulletins listing all OEM-approved products in many materials categories. (Provided by Honda)

A brochure in a 2018 SEMA Honda booth promotes Honda’s OEM repair procedure website, http://techinfo.honda.com. (John Huetter/Repairer Driven News)