New IIHS side-impact tests could change engineering auto body shops encounter

By onAnnouncements | Education | Insurance | Market Trends | Repair Operations | Technology

The Insurance Institute for Highway Safety plans to alter its side-impact crash test for the first time in more than a decade to account for the larger vehicles and higher speeds on the road today.

IIHS seeks to have the redesigned test factored into its ratings by 2022, which could soon make for redesigned vehicle structures and potentially even revised supplemental restraint systems like airbags.

The IIHS’ side-impact crash testing dates back to 2003, back when nearly 10,000 people were dying in T-bone collisions every year.

At the time, OEMs complained that it’d be impossible to pass the test, IIHS senior test coordinator Sean O’Malley told the 2019 Great Designs in Steel last month.

“10 years later, we don’t have a failure in that test,” he said. Most vehicles on the road are rated “good,” the best classification possible.

The federal government already tested vehicles for side impacts back in 2003, but the IIHS felt those studies didn’t account for the rise in SUVs and pickups. “The height of the barrier’s front end is below the heads of the crash test dummies,” the IIHS wrote. “As a result, the federal test doesn’t assess the much greater risk of head injury from impacts with taller vehicles.”

The testing organization instead hit on the current test, which bangs a nearly 3-foot-high 3,300-pound aluminum honeycomb barrier into the side of vehicles at 31 mph.

Fatalities began to plummet, dropping to less than 6,000 annually early this decade. However, the IIHS recently had noted a concerning increase in side-impact deaths, O’Malley said.

In addition, vehicles rated “good” still see occupants seriously injured in T-bone crashes, according to the IIHS. 25 percent of all fatal crashes are in vehicles achieving that top rating (which as noted before, is most vehicles), according to O’Malley.

The IIHS thinks it’s because the moving aluminum barrier weighs less than the growing pool of SUVs and pickups on the road today — a population likely to increase in the future. (GM and Ford, for example, are ditching most of their cars.)

O’Malley said May 15 the existing test’s 3,306.9-pound barrier (1,500 kg) weighs less than the average 2017 model year pickup’s 4,629.7 pounds and 2017 SUV’s 4,188.8 pounds.

“The current side-impact research tests build on a study of real-world side crashes in which people were seriously injured in vehicles with good side ratings from IIHS,” the IIHS wrote April 25 in discussing ongoing side-impact crash testing. “In that study, many of the impacts occurred further forward on the vehicle than the spot where the barrier strikes in the current IIHS test. Many also occurred at higher speeds than the 31 mph used in the test.

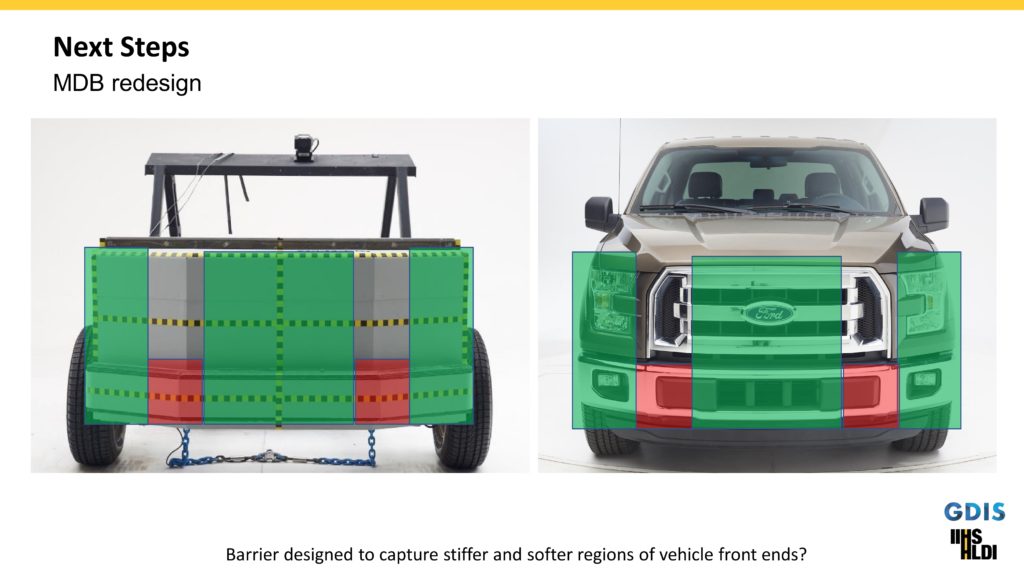

“IIHS engineers have also taken a closer look at the moving barrier and found that it may need to be redesigned to more closely approximate the front ends of SUVs and pickups.”

The U.S. threw out the effective maximum speed limit of 55 mph in 1995, according to the IIHS, which wrote in April that 41 states now allow maximum speeds of at least 70 mph.

The IIHS factored in both these trends to study 37 mph (60 kph) side impacts between test vehicles and either a 2018 Honda Pilot, 2015 Ford F-150, or an typical honeycomb barrier laden with an additional 881.8 pounds (to reach 1,900 kg total), according to O’Malley and the presentation.

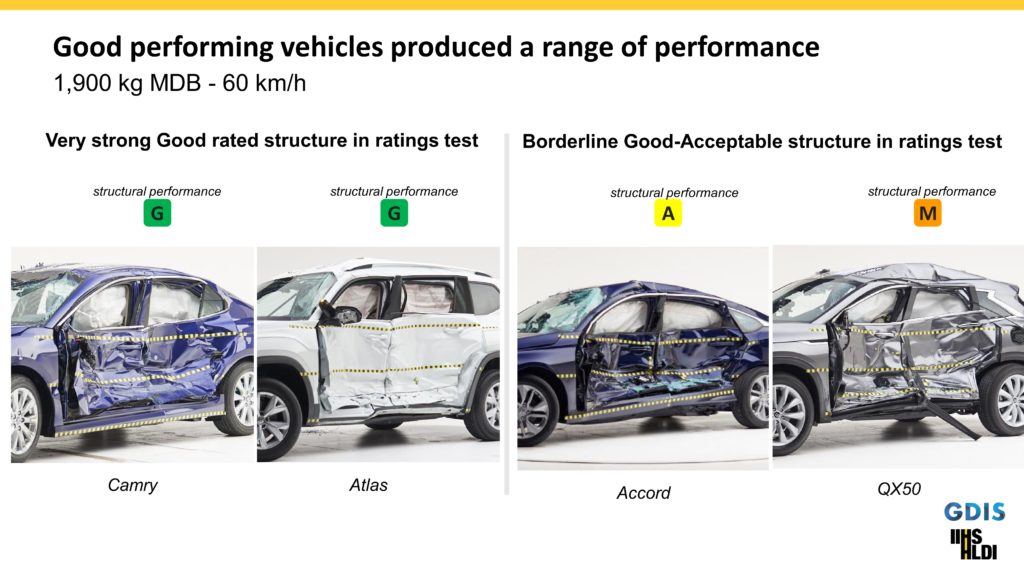

IIHS chose four guinea pigs to receive the blows in the tests, according to O’Malley. The 2018 Toyota Camry and 2018 Volkswagen Atlas selected were very strong “goods” in terms of traditional side-impact performance, according to O’Malley: the collision delivered by the current test still left more than 20 cm of space between the center of the seat and the furthest-intruding point of the B-pillar. However, the Honda Accord and Infiniti QX50 also selected “barely squeaked past” the IIHS’ 12 cm minimum “good” threshold with the test today, O’Malley said. (He didn’t specify the model years.)

O’Malley said the IIHS noticed that all the vehicles behaved differently than they did in the traditional side-impact crash test. They appeared to roll into the impacts with the Pilot and F-150 versus trying to roll away, as vehicles traditionally do with the test barrier. He speculated this was due to stronger B-pillars and softer front ends, but IIHS hadn’t studied the “strange phenomenon” enough to reach a conclusion, he said.

The heavier test barrier bottomed out to its backing plate to crack the 2018 Camry’s windshield and loaded the wheel arch much more than the F-150 did (the F-150’s bumper and fender bent before doing so), while the F-150 caused more damage to the B-pillar, according to O’Malley and the presentation.

The 2018 Camry still would be rated good should it be struck by a heavier, faster barrier, with 17.6 cm of intrusion instead of 22 cm under the test today. However, a hit from an F-150 at 37 mph would knock the vehicle down to an “acceptable,” with the B-pillar just 11.3 cm from the seat center.

The F-150 and heavier barrier produced similar results on the Atlas in another 37 mph crash, O’Malley said. The barrier bottomed out, loading the A-pillar and affecting the roof and windshield, according to O’Malley and the presentation. The F-150’s fender and hood crushed and took the crash energy, taking it easier on the windshield and roof, according to O’Malley and the presentation.

O’Malley said the differences between the F-150 and heavier barrier weren’t as dramatic because the Atlas sits higher than the Camry. However, the heavier, faster barrier knocked what had been a near-record 32 cm of space under the existing side-impact test down to 21.2 cm, while the F-150 strike actually allowed 26.5 cm of room, according to O’Malley and the presentation.

While the Camry and Atlas would have preserved their “good” side-impact ratings in a hit from a 4,188.8-pound, 37 mph (1,900 kg, 60 kph) barrier, the Accord would have fallen to “acceptable” for structural performance, and the QX50 would drop to merely “moderate,” according to the IIHS.

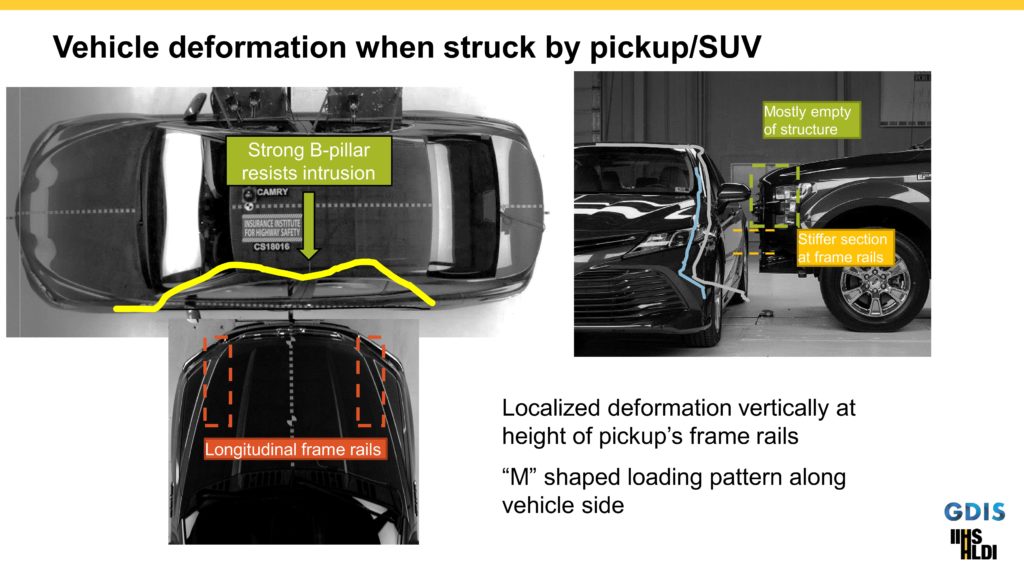

IIHS noticed that the F-150 and Pilot produced an “M”-shaped damage pattern to the impacted test vehicle, O’Malley said. B-pillars on the U.S. fleet are “so strong now” that they withstood the hits from the Pilot and F-150, he said. But the Pilot and F-150’s frame rails plow into the doors and deform them inward past the B-pillar, according to the presentation and O’Malley.

The IIHS’ heavier barrier has uniform stiffness, and so the damage is more of a uniform “D” shape, based on the presentation.

The Pilot and F-150 also produced different injuries, O’Malley said. The dummies T-boned by the SUV and truck were hurt in their chest and/or legs because of the perpendicular frame rails pushing the doors inward, according to O’Malley and the presentation. The heavier barrier’s more uniform impact instead would hurt chests and heads, according to the presentation and O’Malley.

The IIHS now seeks to redesign the barrier to simulate the impact of a vehicle with hard frame rails but other softer areas, and it plans to use a higher speed in the testing, O’Malley said. His presentation indicated the IIHS would use a heavier barrier too.

Manufacturers said they couldn’t pass the original side-impact test in 2003, but “then they did it,” O’Malley noted at the end of his talk. IIHS believed better crash protection was possible, and it was “trying to raise the bar” again, O’Malley said.

It’ll be interesting to see how OEMs respond to such a test either before or upon its tentative introduction in 2022.

Will repairers see more airbags beyond existing side-curtain protection to protect against intruding frame rails? Will the single ultra-high-strength steel anti-intrusion beams seen in doors today receive companions, or perhaps be widened? And will this compensation allow OEMs to reduce tensile strengths on other structures which won’t receive as significant as an impact from a modified IIHS barrier? (As the old adage goes, what gets measured gets done.)

As we’ve noted before, OEMs compensating for new IIHS tests are likely to shake up the engineering even within a single structural design generation — or even a model year’s production run. It’s another reason why auto body shops must check OEM repair procedures fresh online on every vehicle to ensure their repair techniques and initial blueprinting/estimating aren’t incorrect.

More information:

“Using real-world crash data to develop new crash tests”

Insurance Institute for Highway Safety, April 25, 2019

“Update on IIHS side impact research”

IIHS via Great Designs in Steel, May 15, 2019

Images:

The Insurance Institute for Highway Safety plans to alter its side-impact crash test for the first time in more than a decade to account for the larger vehicles and higher speeds on the road today. The barrier might be modified to simulate the front end of vehicles like a truck (Provided by IIHS)

While a Camry and Atlas would have preserved their “good” side-impact ratings in a hit from a 4,188.8-pound, 37 mph (1,900 kg, 60 kph) barrier, the Accord would have fallen to “acceptable” for structural performance, and the QX50 would drop to merely “moderate,” according to the IIHS. (Provided by IIHS via Great Designs in Steel)

IIHS noticed that the F-150 and Pilot produced an “M”-shaped damage pattern to the impacted test vehicle, IIHS senior test coordinator Sean O’Malley said. B-pillars on the U.S. fleet are “so strong now” that they withstood the hits from the Pilot and F-150, he said. But the Pilot and F-150’s frame rails plow into the doors and deform them inward past the B-pillar, according to the presentation and O’Malley. (Provided by IIHS via Great Designs in Steel)

The Insurance Institute for Highway Safety plans to alter its side-impact crash test for the first time in more than a decade to account for the larger vehicles and higher speeds on the road today. The barrier might be modified to simulate the front end of vehicles like a truck (Provided by IIHS via Great Designs in Steel)