CIC session shows need for calibration training, OEM procedures

By onAssociations | Education | Repair Operations | Technology

Collision repairers should get on top of calibration by reviewing OEM procedures and obtaining sufficient training, based on a joint Collision Industry Conference Emerging Technologies and Insurer-Repairer Relations Committee session July 25.

Emerging Technologies Chairman Jack Rozint (Mitchell) noted scanning seemed to sneak up on the industry, and the thought behind the joint session was “‘Maybe we get ahead of this issue.'”

Rozint defined some of the various types of calibration potentially required in a collision repair.

Less involved calibrations involved components like seat weight sensors and steering angle sensors — they can be done in-house with a good scan tool and technician, he said. (You might need weights for the seat sensor, but you get the idea.)

Advanced driver assistance systems can require more effort and equipment. A static calibration keys off of targets, while a dynamic calibration involves the vehicle being driven with a scan tool attached to the car, he said.

Rozint noted recent BodyShop Business survey results found 52 percent of shops hadn’t received any diagnostic training within the past year — but 98 percent of shops were doing calibrations. (Granted, the study also found only 48 percent of shops were doing the work in-house.)

He said that if no one at a shop has trained within the past year on a subject like that, “you aren’t current.”

Rozint pointed to the state of vehicle technology, such as 360-degree real-time monitoring using Doppler radar and cameras or infrared systems tracking body heat and requiring a 98.6 Fahrenheit device mounted on a pole to calibrate.

He said if a shop thought it was positioned for target calibrations, “welcome to what’s coming” in the next two years. A repairer might want to start training, he said.

He noted that even a shop who outsourced calibration might still need training to identify when calibration is required and evaluate the qualifications of subcontractors.

Insurer-Repairer Relations Co-Chairman Matthew McDonnell (Big Sky Collision) said we tend to think of its recalibration as an “‘if'” based on factors like an airbag deploying or a hard hit. But Ford actually calls for a dynamic calibration of a 2017 Ford F-150 following changes like a tire size change or a windshield replacement, he said.

The vehicle needs to be driven 10 minutes at 40 mph with a scan tool hooked to the car, he said. The vehicle will ultimately tell the scan tool “‘and now I’m good,'” Mcdonnell said.

“This is something I wasn’t doing five years ago,” McDonnell said. But this kind of data has been available for a decade, he said.

Eric Newell, director of field operations for asTech and a panelist July 25, said it was “pretty simple” to know when calibration would be needed: any time a module is manipulated outside of factory specifications. (Obviously, this is a rule of thumb — you must still check the OEM procedures.)

This could happen under a variety of circumstances, including an R&I, R&R, an adjustment or damage, Newell said.

A misaligned or uncalibrated component will not always trigger a dash light, nor will it always register during a pre-repair or post-repair scan, he said.

Only the OEM procedures will truly tell you if a calibration is necessary, Newell said. As he described it, a shop should think critically: Was the module manipulated? Then the repair procedures should be checked regarding calibration needs.

He recalled visiting a shop which handled calibrations in-house. A representative said that he had repaired “‘a million Toyotas'” and didn’t pull procedures.

But repair procedures “change daily” and the most up-to-date version is necessary, he said.

Besides build data obtained from an OEM scan tool, repairers also can get a sense of necessary calibration by looking for telltale indicators during a walkaround, according to Newell.

For example, take a BMW with a camera attached to the bumper, he said. Your quick one-hour bumper repair would trigger a recalibration, for you’ve manipulated the system.

Newell called glass something that’s “missed quite often.” A repairer will R&I the glass for a repair to the body and forget to recalibrate the camera behind the component.

Mirrors can have technology embedded within, Newell’s presentation illustrated. He recalled a repairer who told him he removed such a mirror — but “‘I didn’t unplug it.'”

It doesn’t matter, Newell told the CIC audience. The shop still manipulated the mirror outside of OEM specs, which could mean it still needs recalibration.

Newell said Honda repair procedures suggest a front radar recalibration if a vehicle receives a four-wheel alignment.

AirPro operations and technology Senior Vice President Chuck Olsen said a repairer also must be familiar enough with a system to properly document it.

“There are so many systems” and OEM descriptions of those ADAS systems, Olsen said. He said that while a repairer must understand the entire system, their shop (or sublet facility) is actually calibrating components within the system.

He said shops should document “‘what did I do?'” with this in mind: Was blind spot monitoring recalibrated — or was it a blind spot sensor?

The customer might know the name of the system and what it does, but you as the repair professional should be able to document it on a technical basis, he said. The shop would state that a particular sensor was replaced, the service information was reviewed, and the relevant calibration was done.

More information:

NASTF portal to official OEM repair procedures sites

CIC, July 25, 2019

Images:

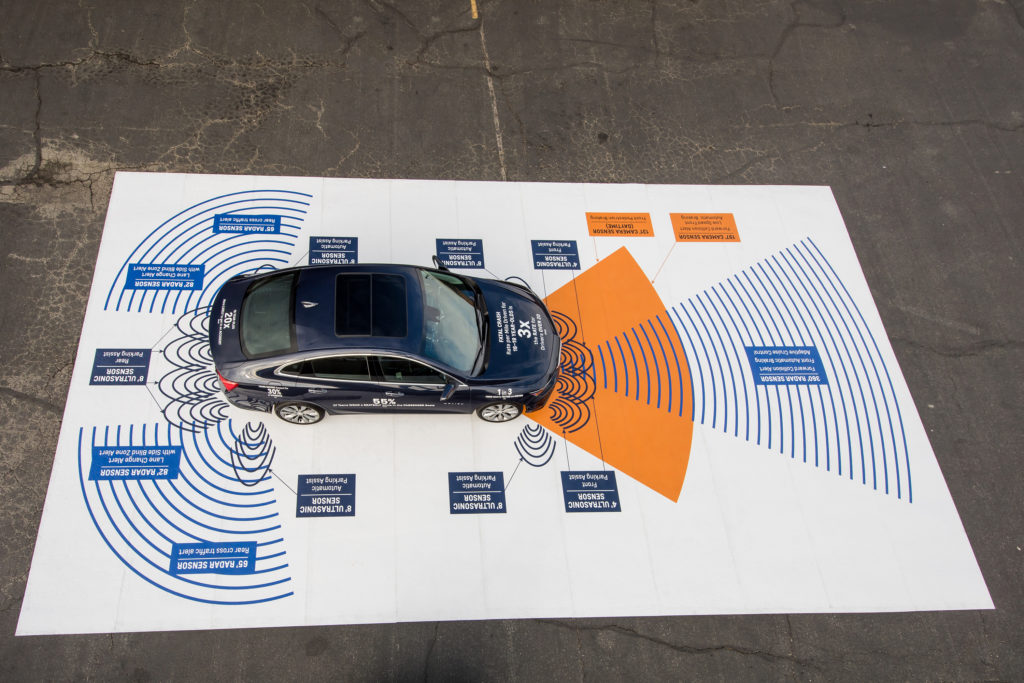

Advanced driver assistance systems possible on the 2016 Chevrolet Malibu are shown in this image. (Copyright General Motors)

Eric Newell, director of field operations for asTech, speaks at a July 25, 2019, Collision Industry Conference Emerging Technologies and Insurer-Repairer Relations Committee session. (John Huetter/Repairer Driven News)

A July 25, 2019, Collision Industry Conference Emerging Technologies and Insurer-Repairer Relations Committee session focused on ADAS calibration. (John Huetter/Repairer Driven News)