‘Who Pays?’: Shops often billing 2 units for frame setup and measure

By onBusiness Practices | Education | Repair Operations | Technology

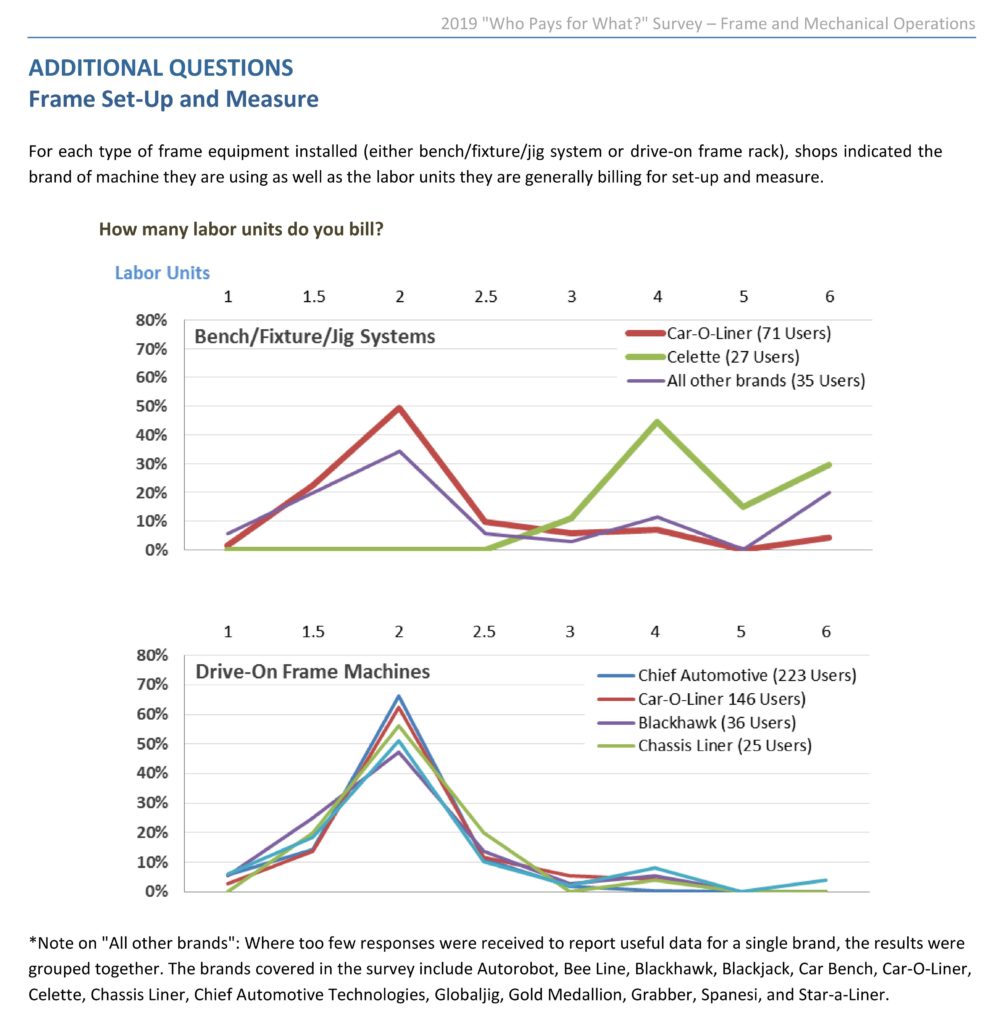

Data from the most recently released “Who Pays for What?” study finds frame “set-up and measure” operations often billed at 2 labor units on either type of frame machine studied.

However, the research conducted in July found a significant portion of repairers calling for even more.

In fact, none of the 27 users of a Celette bench/fixture/jig setup reported billing less than 3.0 units. The most common time for the work on that bench was 4 hours, with 6 the second most common.

50 percent of the 71 shops using a Car-O-Liner bench/fixture/jig setup billed two hours, and another 20 percent called for just 1.5 hours. However, that still meant 30 percent of the repairers requested more than 2 hours for the work.

The 35 shops reporting “other brands” also most commonly charged for 2 units. However, roughly an equal amount charged for 1.5 hours as did 6 units.

Help the industry by taking the current “Who Pays for What?” survey on topics like scanning, calibration and aluminum through Oct. 31. All answers are kept confidential; data is published only in the aggregate.

Drive-on frame machines saw somewhat similar trends. The majority of the more than 400 respondents surveyed said they billed about 2 hours, including more than 60 percent of the 146 Car-O-Liner users and a slightly larger proportion of the 223 Chief users.

Bills for 1.5 units and 2.5 units drew the next largest proportions.

None of the three main estimating services actually provide labor times for setup and measure. It’s a not-included manual operation.

CCC’s P-pages explanation of its thought process might explain Audatex and Mitchell’s rationale as well.

“Due to the different types of frame machines used in the collision repair industry, labor times for frame machine set-up are not developed by MOTOR, nor otherwise included in any operation,” CCC wrote. “Each frame machine manufacturer may have its own unique configurations and setup processes. For example, some machines are of a ‘drive-on’ type while others are of a ‘dedicated bench’ type, and there are procedural differences between the two set-up methods. Additionally, there may be variables unique to the actual vehicle that may increase or decrease frame machine set-up time. MOTOR suggests using an on-the-spot evaluation to determine an appropriate frame machine set-up time.”

Audatex’s labor exclusions include “Setup of a vehicle on a frame machine, dedicated bench, or other measuring / straightening devices. Pulling time is not included (Standard Manual Entry M31 is available).”

Mitchell’s not-included items describe “Structural damage by comparing vehicle under-body, under-hood, and upper-body reference points to accepted, OEM-based dimension specification to identify damage to unibody vehicles.

Some of the repairers charging for 2 labor units automatically might wish to double-check that the work isn’t taking longer in reality.

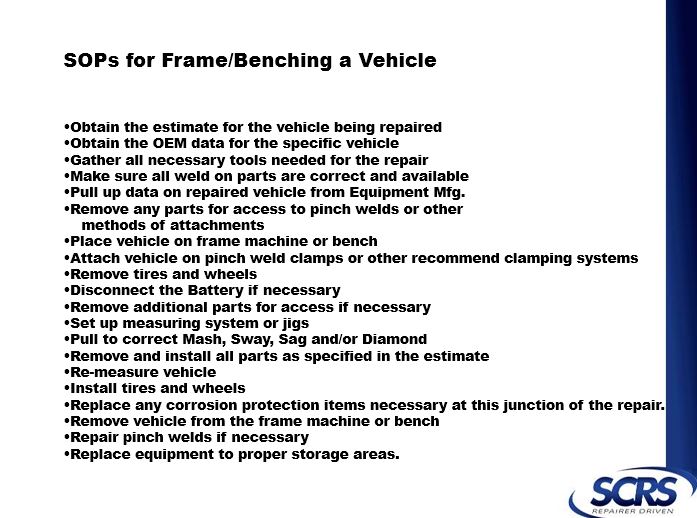

In April 2016, then Society of Collision Repair Specialists Vice President Kye Yeung demonstrated that the setup and measurement process might be more involved than repairers realized. An old adage held that 2-3 hours of setup time was needed, according to Yeung. “It’s not realistic,” he said then.

Nor was a single estimating service line item of “set up and pull,” he told the Collision Industry Conference during a similar presentation that month.

“Line items are quite a bit more than ‘set up and measure,’” he said in April 2016.

The true SOP was along these lines, he argued:

Later that year, SCRS Education Committee and CIC Technical Committee collaborator Toby Chess showed the November 2016 CIC a 30-step presentation demonstrating the effort needed to prepare a dedicated bench.

“This is not for everybody,” he said at the time. “We need to have the training.”

Besides the setup and measurement time, insurers and repairers should understand that a rented bench must be disassembled for return as well, according to Chess.

“This is not a two-minute process,” he said then.

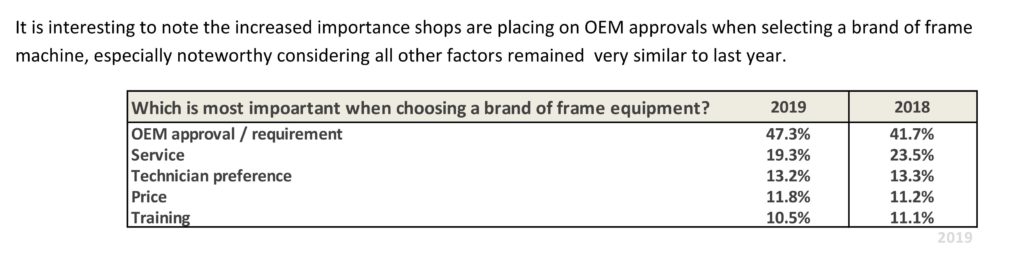

The “Who Pays?” poll by Collision Advice and CRASH Network also asked repairers to state the most important factor in choosing frame equipment.

“It is interesting to note the increased importance shops are placing on OEM approvals when selecting a brand of frame machine, especially noteworthy considering all other factors remained very similar to last year,” Collision Advice and CRASH Network wrote.

47.3 percent of shops declared automakers’ views to be the most important factor — an increase of nearly 6 percentage points over 2018.

More information:

Take the October quarterly “Who Pays for What?” survey

“The Importance of Understanding How Energy Moves in a Vehicle that is Involved in an Accident.”

Society of Collision Repair Specialists Education Committee, April 19, 2016

CIC Technical Committee presentation on dedicated Celette bench setup

Collision Industry Conference, Nov. 2, 2016

Images:

Car-O-Liner EVO parts are shown at the company’s SEMA 2018 booth. (John Huetter/Repairer Driven News)

Data from the most recently released “Who Pays for What?” study finds frame “set-up and measure” operations often billed at 2 labor units on either type of frame machine studied. (Provided by CRASH Network and Collision Advice)

July 2019 “Who Pays for What?” results found more shops declaring OEM requirements or referral to be their most important consideration when selecting a brand of frame equipment. (Provided by CRASH Network and Collision Advice)