Toyota: Check repair procedures to see if occupant sensor reset necessary

By onBusiness Practices | Education | Repair Operations | Technology

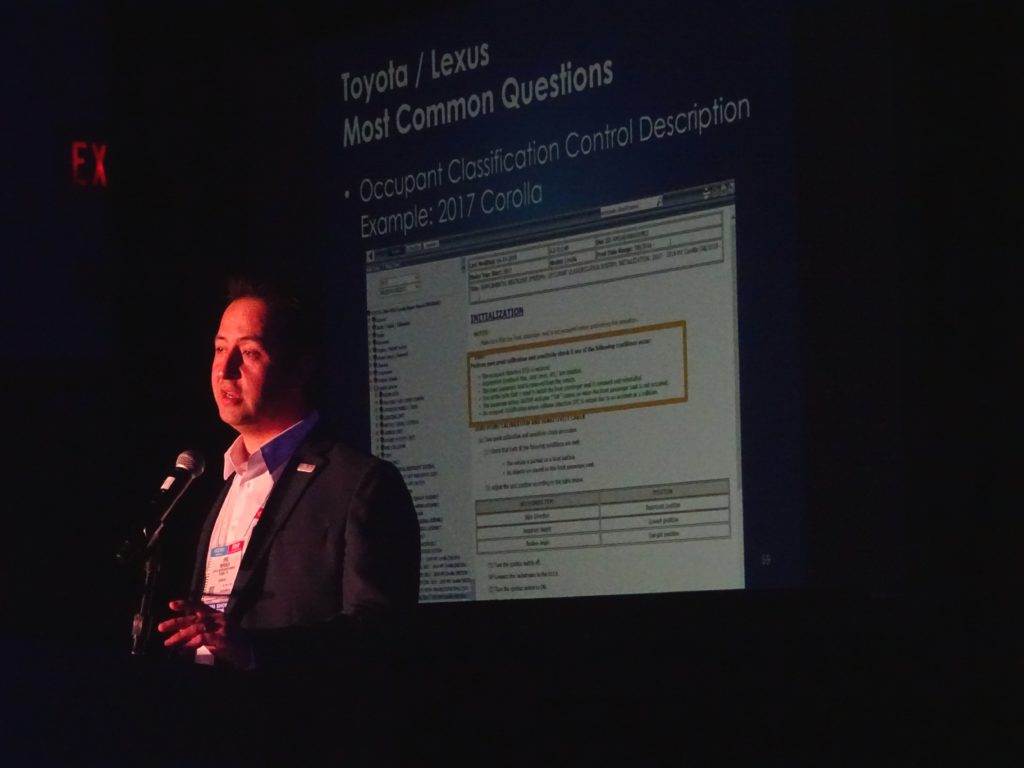

The need for a Toyota Occupant Classification System calibration will vary based on the vehicle being repaired, Eric Mendoza of Toyota collision operations told the SCRS OEM Collision Repair Technology Summit earlier this month.

Questions about when the OCS system needs a reset are among the more common ones encountered, Mendoza said, citing information from OEM Summit session moderator Mike Anderson.

The answer: “Check the repair manual,” Mendoza said.

The sensor evaluates the weight of the front passenger seat occupant to determine if it would be safe to blow the airbag during a collision. For children, an airbag might be more harmful than helpful, so it’s critical shops restore the device to proper working order. An uncalibrated sensor might interpret the occupant’s weight as too low or too high and make the wrong call about deploying the airbag.

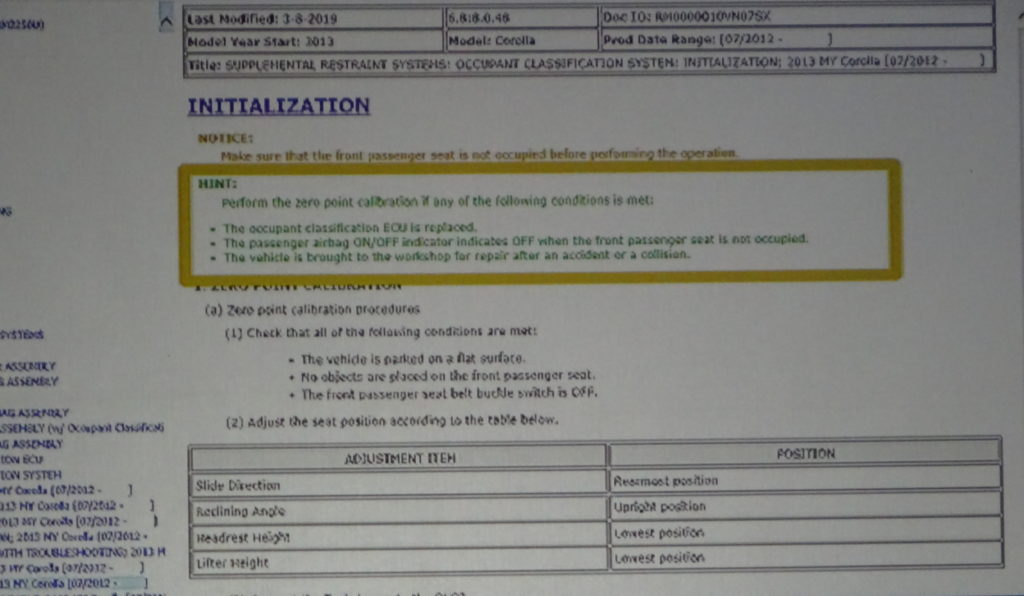

Mendoza showed repair procedures for a 2013 Corolla, which state a zero point calibration must occur “if any of the following conditions” occur:

• The occupant classification ECU is replaced

• The passenger ON/OFF indicator indicates OFF when the front passenger seat is not occupied.

• The vehicle is brought to the workshop after an accident or collision. (Minor formatting edits.)

The third bullet is the key. It means the “vast majority” of vehicles a shop would encounter, Mendoza said.

Such instructions can be found in the “INITIALIZATION” section of the repair procedures, according to Mendoza. A slide he presented showed this could be found within Toyota’s official repair procedure site TIS within Vehicle Interior >> SUPPLEMENTAL RESTRAINT SYSTEMS >> OCCUPANT CLASSIFICATION >> INITIALIZATION.

You should check the INITIALIZATION section on “every vehicle” you fix, Mendoza said.

“This is part of the repair procedures,” he said.

Theoretically, you would be pulling repair procedures anyway on every repair, he said. (Industry best practice demands shops pull the live OEM repair procedures online anew for every single vehicle they fix.)

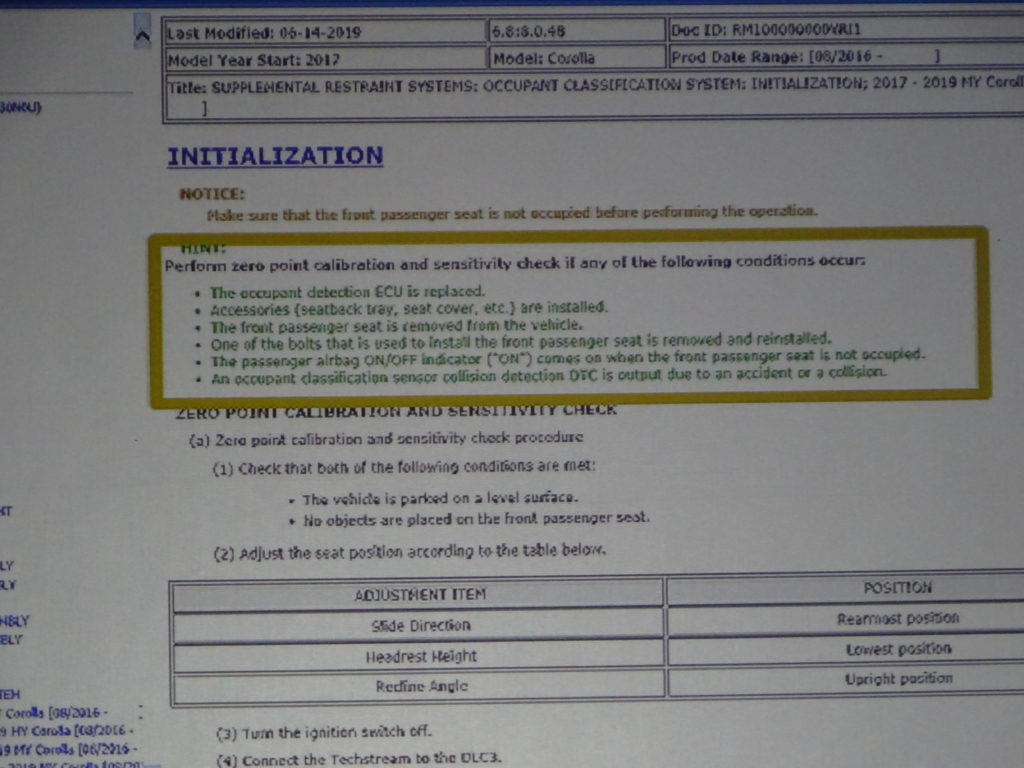

The repair procedures for the 2017 Corolla tell a different story than the instructions for the 2013 model year.

Instead, Mendoza presented instructions for a 2017 Corolla which demand a “zero point calibration and sensitivity check” whenever one of the following occurs:

• The occupant detection ECU is replaced.

• Accessories (seatback tray, seat cover, etc.) are installed.

• The front passenger seat is removed from the vehicle.

• One of the bolts that is used to install the front passenger seat is removed and reinstalled.

• The passenger airbag ON/OFF indicator (“ON”) comes on when the front passenger seat is not occupied.

• An occupant classification sensor collision detection DTC is output due to an accident or a collision. (Minor formatting edits.)

That 2017 Corolla’s OCS doesn’t need a reset on every collision, Mendoza said. Instead, the shop would scan the car and look for a diagnostic trouble code to make that determination. (Assuming, of course, that recalibration wasn’t already a given based on one of the other criteria.)

Same manufacturer, “two different processes,” remarked Anderson, the CEO of Collision Advice.

The need for a Toyota Occupant Classification System calibration will vary based on the vehicle being repaired, Eric Mendoza of Toyota collision operations told the SCRS OEM Collision Repair Technology Summit on Nov. 7, 2019. Instructions for a 2017 Corolla are seen on this Toyota slide from the presentation. (Toyota slide; photo by John Huetter/Repairer Driven News)

Blind spot monitor angle

The OEM Summit highlighted another procedure shops might not be grasping. Anderson said one of the things he sees “most commonly missed” on Toyotas and some Lexuses involved the blind spot monitor.

If you are replacing a quarter panel, you need to remove and reinstall the blind spot monitor, Anderson said. However, repair procedures also dictate that you can’t subject the part to “any strong impact” — which means you have to remove the component before repairing the quarter panel as well, he said.

Reinstalling the blind spot monitor demands a shop perform an angle installation inspection on the part before painting the vehicle, he said.

“This is not a calibration,” Anderson said. “This is an angle installation inspection.”

Mendoza called the bracket placement “very important” for the blind spot monitor to work properly.

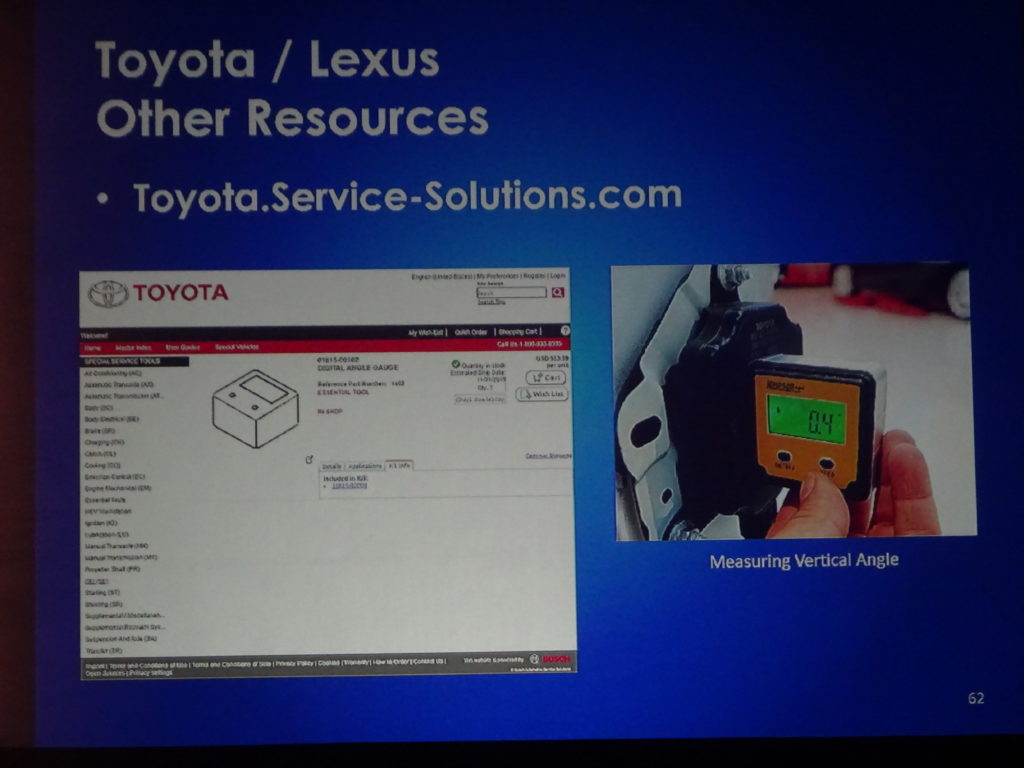

A shop would check the angle of the monitor with a gauge available from Toyota, Anderson said, calling it a “great tool” to buy. Mendoza said a “more primitive way” to check the angle involves a plumb bob and string.

“You absolutely need this tool” if your shop fixes Toyotas with blind spot monitors, Anderson said of the gauge.

Resources

The gauge and other authorized Toyota tools are available on http://toyota.service-solutions.com. Mendoza said you can also buy the official weights to recalibrate the OCS there.

Other sites highlighted by Toyota included the free Collision Repair and Refinish Training website, www.crrtraining.com. A “host” of reference materials were there, Mendoza said.

Anderson urged the audience to visit the site and subscribe to Collision Pros magazine for free. The magazine is all-digital now, Mendoza said.

Mendoza also showed the site’s quick training guides and Painters Corner site.

And of course, Toyota’s OEM repair procedure website for independent repairers is techinfo.toyota.com. (For dealers, it’s one.tis.toyota.com.) One of Mendoza’s slides said shops will need to use either the Internet Explorer 8, 9 or 10; Chrome; or Firefox 21 or later Web browsers to use the site. They’ll also need Adobe PDF Reader 7.0 or later, Adobe Flash 11.0 or later and Java Version 6, Update 7. Check the Toyota website for the most current requirements, for they may change.

More information:

Toyota Collision Repair and Refinish Training

Images:

The passenger seat of the 2011-13 Toyota Corolla refresh generation is shown. The occupant classification sensor on the 2013 Corolla must be recalibrated after conditions including a collision, Toyota confirmed Nov. 7, 2019. (Provided by Toyota)

The need for a Toyota Occupant Classification System calibration will vary based on the vehicle being repaired, Eric Mendoza of Toyota collision operations told the SCRS OEM Collision Repair Technology Summit on Nov. 7, 2019. Instructions for a 2013 Corolla are seen on this Toyota slide from the presentation. (Toyota slide; photo by John Huetter/Repairer Driven News)

The need for a Toyota Occupant Classification System calibration will vary based on the vehicle being repaired, Eric Mendoza of Toyota collision operations told the SCRS OEM Collision Repair Technology Summit on Nov. 7, 2019. Behind him are instructions for a 2017 Corolla. (John Huetter/Repairer Driven News)

The need for a Toyota Occupant Classification System calibration will vary based on the vehicle being repaired, Eric Mendoza of Toyota collision operations told the SCRS OEM Collision Repair Technology Summit on Nov. 7, 2019. Instructions for a 2017 Corolla are seen on this Toyota slide from the presentation. (Toyota slide; photo by John Huetter/Repairer Driven News)

A Toyota blind spot monitor angle installation inspection gauge is seen here and in a screenshot from Toyota’s tools site. (Slide by Toyota; photo by John Huetter/Repairer Driven News)