SCRS/SEMA session highlights worker safety OSHA requirements

By onBusiness Practices | Education

A recent Repairer Driven Education (RDE) presentation delivered by members of the 3M Personal Safety Division at the 2021 SEMA Show provides a wealth of information on Occupational Safety and Health Administration laws regarding Personal Protective Equipment (PPE) and other steps to ensure worker safety.

OSHA requires businesses to have a certified hazard assessment on hand, according to 3M Personal Safety Division Application Engineering Specialist Scott Shinn. OSHA’s standards, laws and regulations are available on the administration’s website.

“That’s the easiest thing to do and probably the most common piece of documentation that isn’t available,” Shinn said.

Shinn covered proper respiratory, hearing and eye protection. It’s important for employers to know that OSHA standards are laws while information from the National Institute for Occupational Safety and Health (NIOSH) and American Conference of Governmental Industrial Hygienists (ACGIH) are best practice guidance, Shinn said. Some OSHA standards require NIOSH-approved PPE.

The presentation is one of several sessions that can be accessed on the online RDE platform.

Respiratory protection

OSHA requires the determination of exposure levels so occupational exposure limits (OEL) – the amount of time workers can be exposed eight hours a day, 40 hours a week during their working lifetimes without adverse health effects – can be followed.

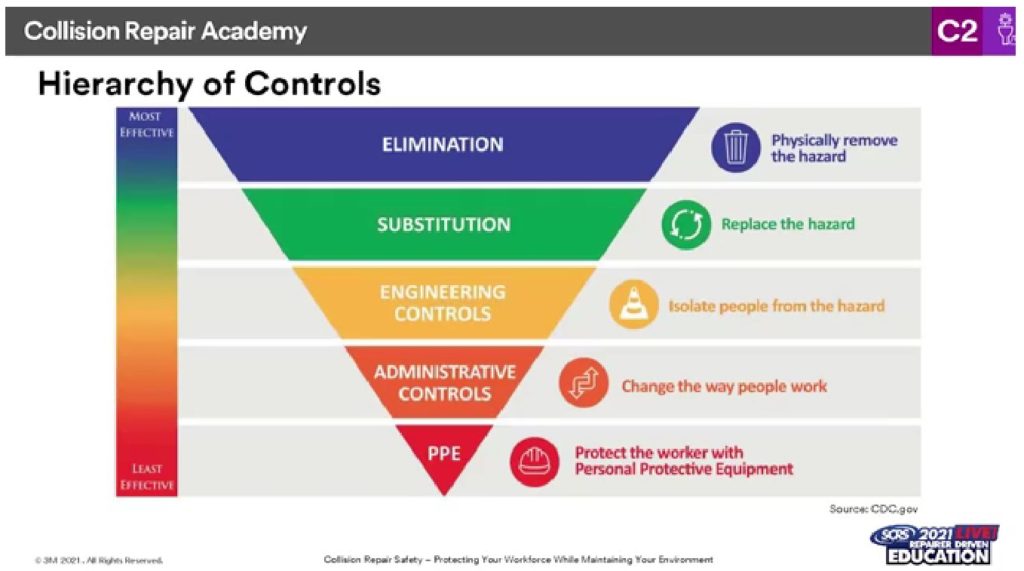

OSHA requires businesses to follow a hierarchy of controls. PPE is often jumped to first but is actually at the bottom of the hierarchy.

The respiratory protection program is likely the most complicated OSHA regulation, Shinn said. A written program is required that explains how the shop’s respirators were chosen, designates who will conduct medical evaluations as well as when, how and where fit testing will be done. Fit testing ensures the correct respirators are chosen depending on for what operations they’re worn and the workers’ facial hair.

Supplied air systems in paint booths need to provide grade D breathable air. The use, care and maintenance of respiratory protection, training and annual evaluations needs to be included in the respiratory protection program. A program administrator needs to be designated in the document. The program should be reviewed and updated at least annually, Shinn said.

“Say what you do, do what you say and verify both,” Shinn said of the program. “Put what you’re going to do in your program. Follow those instructions and verify them. Document everything – the good, the bad and the ugly. We would rather see you uncover issues with the program and fix them than to not know they exist. That’s what OSHA is going to look for when they come in and audit your program.”

All safety requirements should be known and followed by visitors.

PPE needs to be NIOSH-approved and reduce worker exposure from hazardous levels to acceptable levels. Filters need to be maintained or replaced regularly and carbon monoxide testers need to be tested and calibrated periodically. OSHA requires air source testing to ensure grade D air is being supplied but doesn’t provide guidance on how often testing should occur, Shinn said. 3M recommends monthly testing for sources that are used daily or weekly and if used less than weekly, such as monthly or once a year, testing should be done before each use.

More information about proper respirator fitting is available on the NIOSH website.

Hearing loss

Globally 430 million people have some form of disabling hearing loss, according to the World Health Organization’s March 2021 “World Report on Hearing.” Noise is considered a public health issue and a top environmental risk, according to the report.

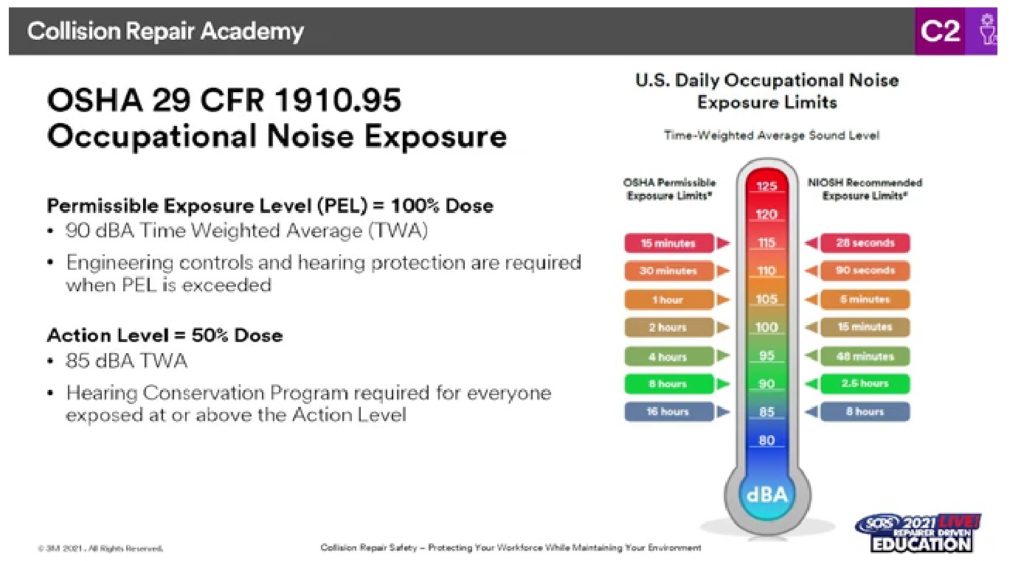

There has been a lot of debate over the past decade on how loud is too loud, Shinn said. NIOSH recommends 85 decibels as the limit for eight hours while OSHA sets the limit at 90 decibels for the same length of time. Both recommend engineering controls and PPE when there is exposure above those levels.

“The thing with noise is there’s no blood; there’s no pain, generally,” Shinn said. “You gradually lose your hearing without even knowing it. … It’s not just occupational exposure. … This is something workers can really take home with them.”

Many companies are offering PPE they can take home with them so they can put ear plugs in when, for example, they’re mowing, he added

If exposure is above 85-90 decibels, OSHA requires employers to implement a hearing conservation program and offer Hearing Protection Devices (HPD) to employees. HPDs are mandatory for exposure above 90.

Employers should keep in mind that HPDs are more likely to be worn if they heir more on the side of comfort, Shinn said. There is also such a thing as overprotection – when employees can’t communicate, hear alarms or vehicle movement with HPDs on, which poses safety risks. The “sweet spot” is 75-85 decibels with HPD on, according to Shinn.

Eye protection

The most important takeaway when it comes to eye protection in the workplace is proper fit to ensure dust or other particles from workers’ hair or in the air doesn’t enter the PPE.

“When you do your hazard assessment you need to look beyond just the more commonly recognized high impact, high velocity type hazards,” Shinn said. “Body filler dust that stays suspended in the air has the potential of getting in the eye and causing what we call foreign body eye injury.”

3M’s worker safety website provides more information and products. Questions can be emailed to 3MCollisionRepairAcademy.@mmm.com.

MORE EDUCATION

SEMA recently launched a new virtual education website. Find out more at repairerdrivennews.com/2021/12/27/sema-launches-new-virtual-education-website/.

IMAGES

Featured image: 3M Personal Safety Division Application Engineering Specialist Scott Shinn covered OSHA standards for PPE in the workplace during the 2021 SEMA Show. (Screenshot from SCRS Video)

Shinn gave an overview of OSHA’s hierarchy of controls for worker safety. (Screenshot from SCRS Video)

Shinn discussed OSHA’s U.S. Daily Occupational Noise Exposure Limits. (Screenshot from SCRS Video)

Shinn gave examples of eye and face PPE. (Screenshot from SCRS Video)