DOT lab works with Hyundai to improve safety of EV batteries in high-speed crashes

By onAnnouncements | Technology

Researchers at the National Renewable Energy Laboratory (NREL) are working to make electric vehicles (EVs) safer by studying ways to make high-voltage batteries more resistant to damage during high-speed crashes.

Through a collaboration with Hyundai, NREL said it hopes to be able to further strengthen the resilience of EV batteries by improving the amount of heat the battery is able to withstand when damage occurs.

NREL is a national laboratory of the U.S. Department of Energy that focuses on the research and development of renewable energy, energy efficiency, energy systems integration, and sustainable transportation.

“Our goal is to understand how mechanical damage leads to battery failure and internal short-circuiting,” NREL researcher Anudeep Mallarapu said in a statement. “Cell-level damage tends to cause a chain reaction within the battery. However, if we manage the heat generated, we can reduce the likelihood of thermal runaway and improve overall battery safety.”

According to NREL, both the Insurance Institute for Highway Safety (IIHS) and the National Highway Traffic Safety Administration (NHTSA) have concluded that EVs are at least as safe as conventional vehicles. “In a collision, EV batteries automatically disconnect from the vehicle to reduce battery damage. In addition, current EV vehicle designs boast a lower center of gravity, offer improved stability, and decrease the likelihood of a rollover accident,” it said.

“The key to designing durable, reliable, and safe EV batteries lies in understanding how damage impacts the battery module,” NREL said. “With battery data in hand, NREL researchers can also develop predictive battery abuse models that easily integrate with existing vehicle crash simulations.”

NREL has developed new capabilities to evaluate battery performance in “dynamic, high-speed impacts.” The tests begin with in-lab tension and compression experiments at the component level; progress to high-speed, 10,000-40,000-image-per-second recording as the cell is damaged, and conclude with a detailed analysis of the thermal and electrochemical reactions, determining how gas and temperature distribution evolves during battery failure to show how designs can be improved.

NREL has developed new capabilities to evaluate battery performance in “dynamic, high-speed impacts.” The tests begin with in-lab tension and compression experiments at the component level; progress to high-speed, 10,000-40,000-image-per-second recording as the cell is damaged, and conclude with a detailed analysis of the thermal and electrochemical reactions, determining how gas and temperature distribution evolves during battery failure to show how designs can be improved.

“Most accidents don’t happen slowly, and battery research should reflect real-world scenarios,” Mallarapu said. “High-speed abuse testing is crucial to our understanding of the safety and reliability of EV batteries.”

Hyundai and MREL use the test results to create mathematical models and computer simulations that can “streamline” crash evaluations for EV batteries. “By validating these impact models against the in-lab experiments, researchers can more quickly analyze the battery response to different types of mechanical damage,” MREL said.

YongHa Han, who leads Hyundai’s Virtual Technology Innovation Research Laboratory, said the research may help improve the fire safety of EVs.

“As concerns about the fire safety of high-voltage batteries increase with greater adoption of electric vehicles, it is essential that we develop multiphysics simulation techniques capable of predicting this danger in advance,” Han said.

“Under these circumstances, collaboration with specialized research institutions such as NREL, which has abundant development experience and capabilities related to electric vehicle batteries, is essential. We hope that the core element technologies needed for Hyundai Motor Group will be effectively developed by establishing a continuous joint research and cooperation system.”

The final phase of the collaboration calls for scaling the research from battery modules to entire battery packs, to see how cells react when multiple modules are damaged. NREL expects future research to improve crash simulation technology and speed up the evaluation of EV designs.

Images

Featured image: NREL materials science researcher Anthony Donakowski prepares a battery impact testing device for a demonstration during a recent meeting with Hyundai officials. (Werner Slocum/NREL)

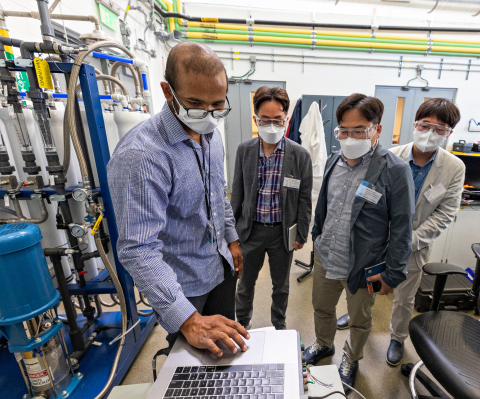

Mechanical engineer researcher Anudeep Mallarapu demonstrates NREL’s battery safety modeling and experimentation during a recent meeting with Hyundai officials. (Werner Slocum/NREL)