More details provided on development of hydrogen-fueled BMW

By onMarket Trends | Technology

BMW and partner, Garrett Motion, have revealed more about the components behind the automaker’s BMW iX5 Hydrogen prototype.

The automotive tech company’s advanced electric fuel cell compressor (FCC) powers the vehicle along with BMW’s hydrogen fuel cell drivetrain.

The hydrogen-fueled iX5’s fuel cells generate on-demand electricity for electric motors via an electrochemical reaction between hydrogen and oxygen in the air supplied to the fuel cell stack.

To perform this reaction efficiently, and to produce maximum power output, the fuel cell stack is fed with optimal airflow and pressure, as required, which Garrett’s compressor provides. It also maximizes the efficiency and durability of the fuel cell stack over the vehicle’s lifetime.

A new turbine expander — designed to recuperate waste energy from the fuel cell stack’s outlet — enables up to a 20% reduction in electricity consumption for air compression when compared to conventional fuel cell compressors, according to Garrett.

“For the last four years, we have been working closely with BMW Group to develop an advanced hydrogen fuel cell compressor tailored to their exact needs.'” said Craig Balis, Garrett vice president and chief technology officer. “This effort will culminate in an in-depth, on-road trial later this year.

The new compressor comes from Garrett’s continued tech investments and “is consistent with our commitment to being at the forefront of hydrogen-powered propulsion systems,” Balis added.

During the development phase, Garrett tested the BMW iX5 Hydrogen and its key components, including the fuel cell electric compressor and its inverter, against harsh temperatures, humidity, and vibration levels.

“From a technical point of view, the technology is suitable for SUVs and sedans,” BMW told Repairer Driven News. “We have significantly reduced the size of the fuel cell since the first generation and expect this trend to continue in subsequent generations. As you can see from the iX5 Hydrogen, the technology fits perfectly in our current models, like the BMW X5, which was not originally designed for an FCEV drivetrain.

“From a use case perspective, we see hydrogen playing a role for long-distance travel and heavier vehicles. For short distances, we see battery electric vehicles having quite a significant role.”

Specific potential future vehicle models haven’t been shared.

In February, the first BMW iX5 Hydrogen vehicles hit the road to be tested. The pilot fleet will be driven worldwide by various target groups for trial and demonstration purposes. BMW says the test runs give the development team valuable practical knowledge about the vehicle and the everyday use of hydrogen fuel cell technology.

The BMW iX5 Hydrogen generates a high continuous output of 125 kilowatts per 170 horsepower. The iX5’s powertrain can deliver 275 kW/374 hp due to its fuel cell system, BMW’s fifth-generation eDrive technology electric motor, and a high-performance battery. The drive system is comprised of two hydrogen tanks, a fuel cell, and an electric motor.

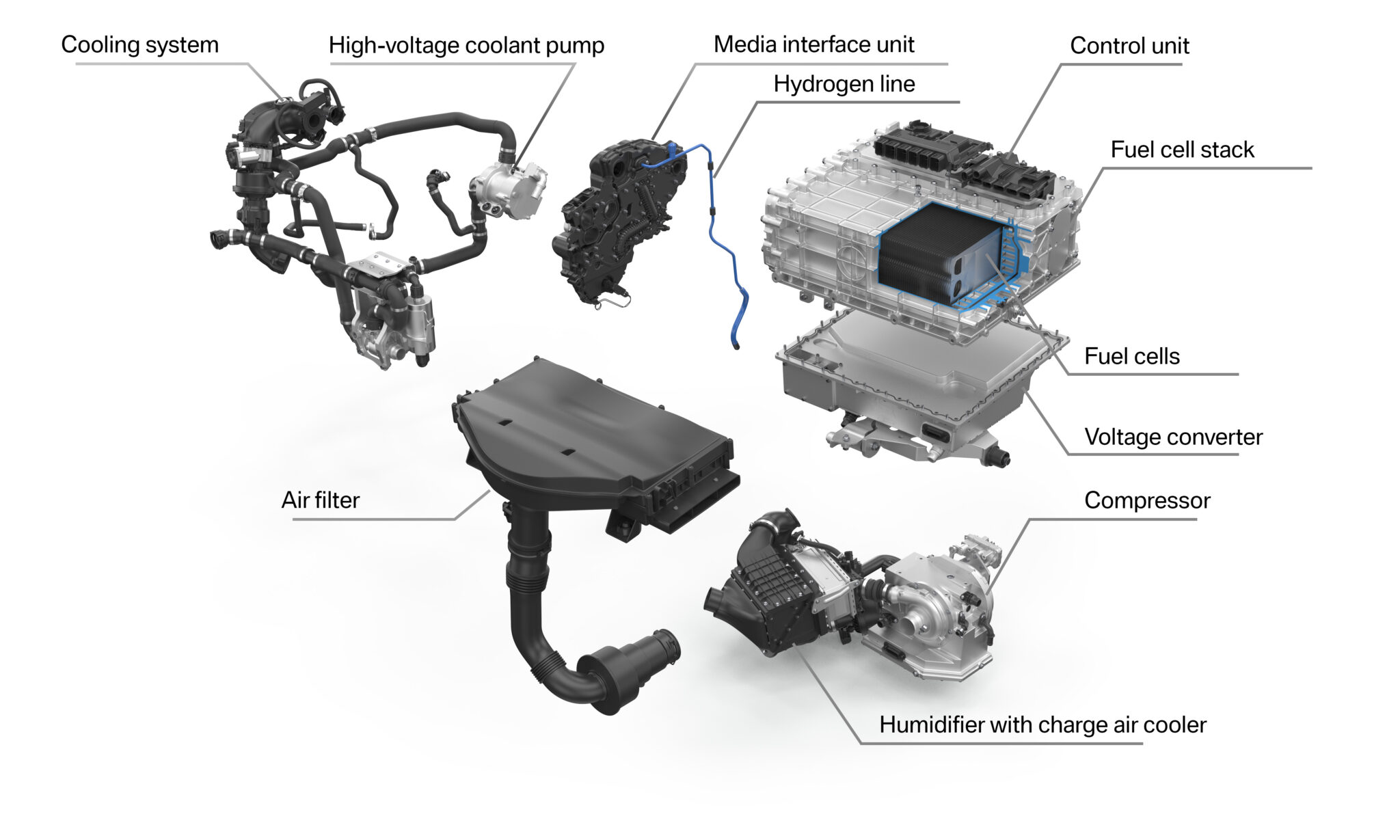

In addition to the technological equivalents of features found on combustion engines, such as charge air coolers, air filters, control units, and sensors, BMW also developed special hydrogen components for its new fuel cell system including a high-speed compressor with a turbine and high-voltage coolant pump.

In addition to the technological equivalents of features found on combustion engines, such as charge air coolers, air filters, control units, and sensors, BMW also developed special hydrogen components for its new fuel cell system including a high-speed compressor with a turbine and high-voltage coolant pump.

Positioned in the rear axle area along with the high-performance battery, the electric motor is a product of the current, fifth-generation BMW eDrive technology also employed in battery electric and plug-in hybrid models from BMW. The fuel cell systems located under the hood of the BMW iX5 Hydrogen have been manufactured at BMW’s in-house competence center for hydrogen in Garching to the north of Munich since August.

Thatcham Research, Toyota Motor Manufacturing (UK), and a consortium of specialist industry partners are also working together to develop a hydrogen version of Toyota’s iconic Hilux pickup. The consortium plans to adopt Toyota Mirai fuel cell components to transform the pickup into a hydrogen fuel cell vehicle. The multi-year project will result in the production of initial vehicle prototypes throughout 2023 at TMUK’s Burnaston site in the UK.

Images

Featured image: BMW’s iX5 Hydrogen (Credit: BMW Group)

The engine under the hood of the BMW iX5 Hydrogen (Credit: BMW Group)