UPDATE Parts import data from PartsTrader can affect labor, CCC solution provided

By onCollision Repair

Editor’s note: This story has been updated to include comment from PartsTrader. The original version stated in error that no comment had been given by the publication deadline.

An Illinois body shop manager recently made a discovery and reached out to the Database Enhancement Gateway (DEG) for guidance, which resulted in solving a likely overlooked labor payment glitch within CCC ONE.

When using PartsTrader in conjunction with CCC ONE to create repair orders, labor times input for OEM parts are automatically substituted for recycled parts under “parts types.”

In the original inquirer’s case, a recycled door selection for a 2013 Chevrolet Terrain was modified to include R&Is in the labor time, which made the total labor time less than the system would have otherwise generated.

“It made all the R&Is included to the door as if you were putting a new door on, but it kept 1.4 hours to put the door on,” the shop manager, who wished to remain anonymous, said. “At least in CCC… they’re considering you’re getting a used door as an assembly and you’re putting that door on as an assembly then you have to add all of your R&Is — your door handle, all your trim — that you would normally.”

He noted that labor times shouldn’t be affected by part type. Rather, part types should only affect the cost of the parts.

The cause isn’t clear.

“As a parts procurement platform, PartsTrader provides our partners with CIECA industry standard codes that correctly identify the part and part type selected by the repairer,” PartsTrader told Repairer Driven News. “While we are sensitive to these issues, we are not able to control how information providers calculate labor on their estimating platforms.”

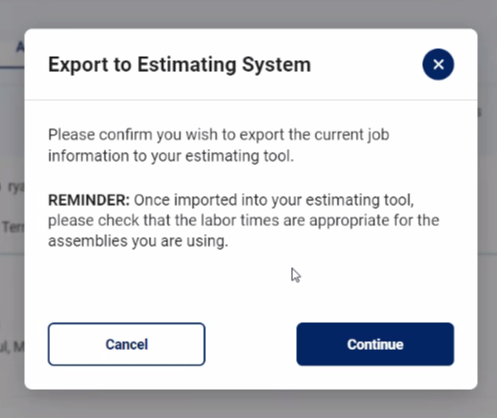

CCC Intelligent Solutions Product Management Vice President Mark Fincher told RDN that when users import part lines from PartsTrader into CCC ONE they need to carefully check each part line of the work file for accuracy.

“When an existing part line is overwritten by the PartsTrader import using a recycled part, the new part line will be imported as a manual line entry, including labor and refinish times,” he said.

“To manage this import process, CCC ONE users may choose to take note of the part price and part number of the recycled part, delete the imported recycled part line, and replace that line using the recycled option for the same part using the CCC ONE database. Once the recycled assemblies dialog box appears, the user may then input the part price previously provided by PartsTrader. Additional R&I operations can then be selected from the recycled dialog box. Selecting ‘add with changes’ will allow the user to update the recycled part with the part number provided by PartsTrader.

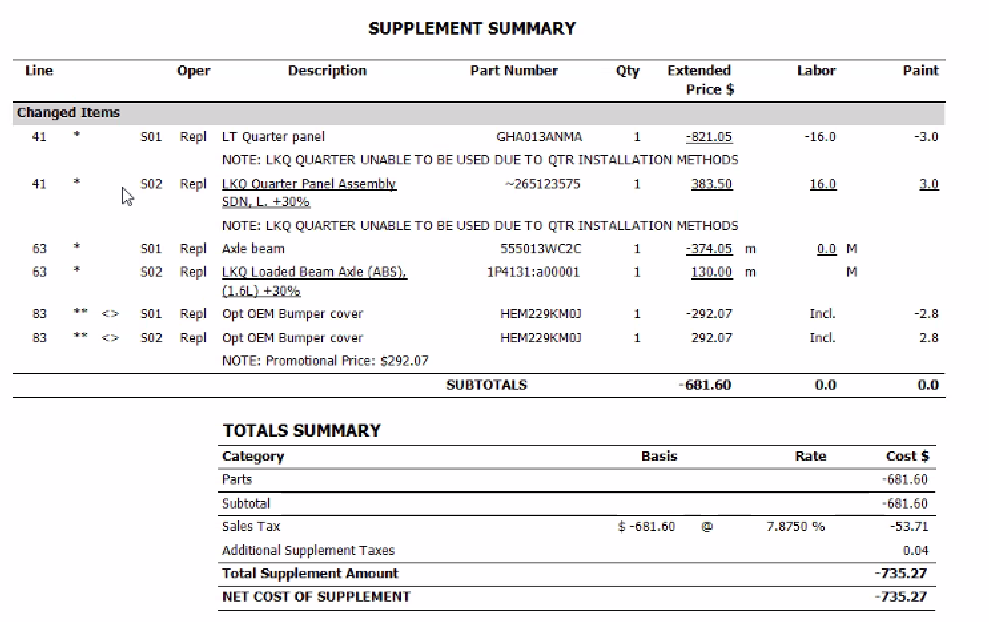

DEG provided an example of how the issue can affect repair order totals:

Prior to CCC providing a solution, DEG Administrator Danny Gredinberg was able to find a temporary workaround for the shop manager in June.

“When I reviewed the sheet, the door shell on their estimate was showing recycled but it wasn’t done in the way that you’re supposed to do it in CCC so we confirmed that the shop had used PartTrader,” Gredinberg said.

“It had imported back into CCC, the repair estimate, a recycled door shell and modified it in a way that would trigger the labor operations to be considered as a new replacement part versus a new recycled door but changed the description only. That can cause missed labor, if it’s not correctly utilizing the estimate system.”

A Society of Collision Repair Specialists (SCRS) “Quick Tip” video with Mike Anderson of Collision Advice and DEG’s Danny Gredinberg covers why recycled parts may require additional, not-included labor operations that wouldn’t be necessary with a new replacement part:

Images

Featured image credit: gilaxia/iStock

Secondary images provided by DEG