DEG Estimating Tips: O/H operations, flash & wait time, frame replacement

By onAnnouncements | Collision Repair

Three recent Database Enhancement Gateway (DEG) Estimating Tips explore adjustments and responses to inquiries on a Solera Qapter (Audatex) Rear Door Replacement time and unintended overlap deductions, MOTOR guide updates defining flash and wait time as not-included, and a Mitchell identification of the “Frame” labor for frame replacement.

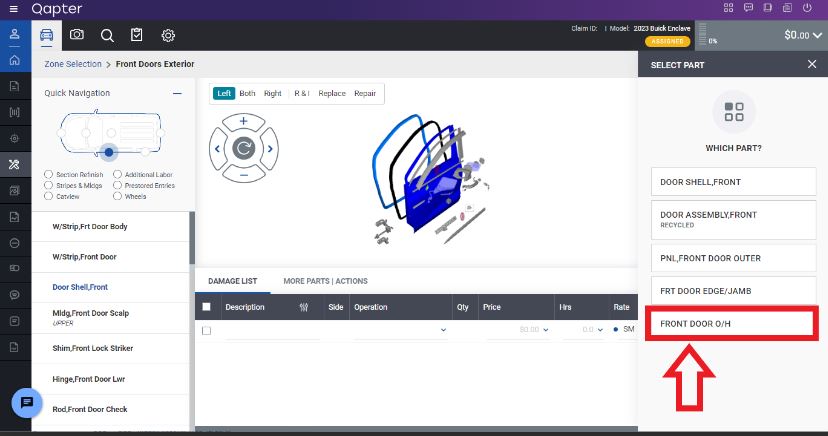

In an inquiry addressing the Rear Door on a 2020 Jeep Cherokee, Solera concluded that after review, the labor allowance in Qapter would increase before option and/or overlap considerations. “The labor allowance for the PANEL RR DOOR OUTER (GN 0289/0290) has changed from 6.9 hours to 7.4 hours, the replacement time for the outer panel has changed from 3.0 hours to 3.5 hours.”

The inquiry also led way to an estimating tip that highlighted an important workflow note. According to Solera the REAR DOOR O/H operation, designed for removing and installing parts for repair or painting, cannot be used concurrently with PANEL RR DOOR OUTER (GN 0289/0290) due to system limitations causing overlap deductions.

“To prevent confusion and maximize efficiency, it is recommended to choose only PANEL RR DOOR OUTER (GN 0289/0290) replacement and perform the necessary R&I of associated parts,” Solera Qapter said.

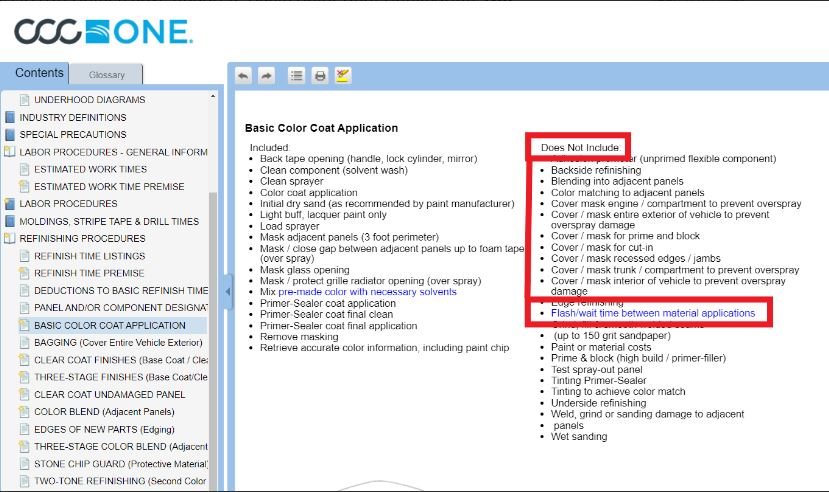

According to a Dec. 18 estimating tip, MOTOR Guide to Estimating (GTE) has updated updated the “Basic Color Coat Application” to not include “Flash/wait time between material applications.”

Flash and Cure consideration would be an “On the Spot Evaluation.”

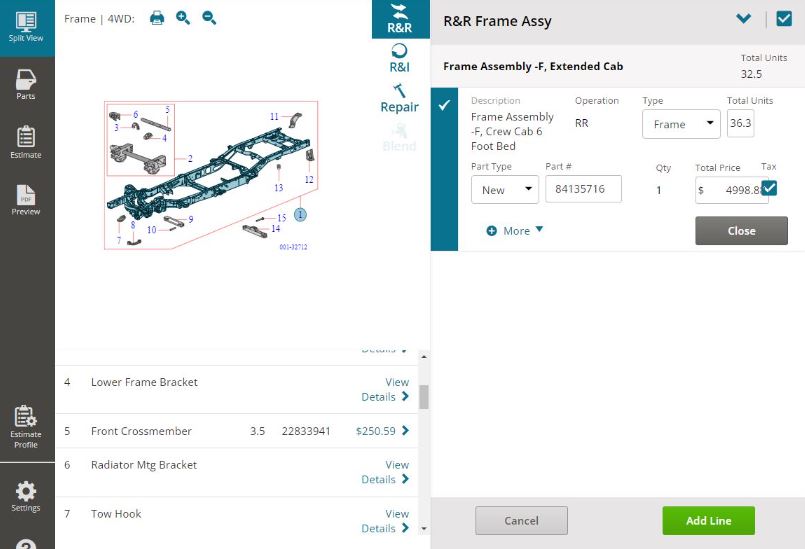

Mitchell’s response to DEG Inquiry 35578 provides help for frame replacement labor classification.

“Frame R&R is a unique operation where one labor time represents multiple individual operations,” the response said. “The ‘Frame’ labor category, when used for Frame Assembly R&R, represents a blend of mechanical and body operations. In other words, a certain percentage of the labor is mechanical in nature and a certain percentage is body. This blend will vary from vehicle to vehicle and the rate for this category could be adjusted to reflect the job-specific blend of operations.”

The time for repair can vary depending on the severity of the collision, vehicle condition, shop equipment, and technician skill sets, the response said.

“Good planning, proper preparation, and thoughtful job sequencing are all key to performing Frame Assembly R&R,” the response said. “Also, special equipment, additional workspace, and manpower may be needed.”

P-pages allow for repairers to change the system default labor category depending on the user’s circumstances, according to the response.

“See ‘Labor General Information – Labor Categories’ where it says, in part, ‘The labor times shown in the Guide fall into various categories (for example, body, frame, mechanical) as determined by the repair facility’s operating procedures. As a guide, components for which R&I or R&R is commonly considered to be a mechanical operation when performed in a collision repair environment are designated with the letter ‘m’ in the text. These designations are only a guide. They are not necessarily all inclusive…’” the response said.

To find more DEG Estimating tips, visit https://degweb.org/estimating-tips/.

Images

Photos courtesy of DEG