WorldAutoSteel provides updated joining procedures for MaaS AV body structure concept

By onTechnology

WorldAutoSteel, the World Steel Association’s automotive group, and Ricardo, its engineering partner, have shared updated information on the joining techniques of its Steel E-Motive initiative for autonomous vehicle design concepts.

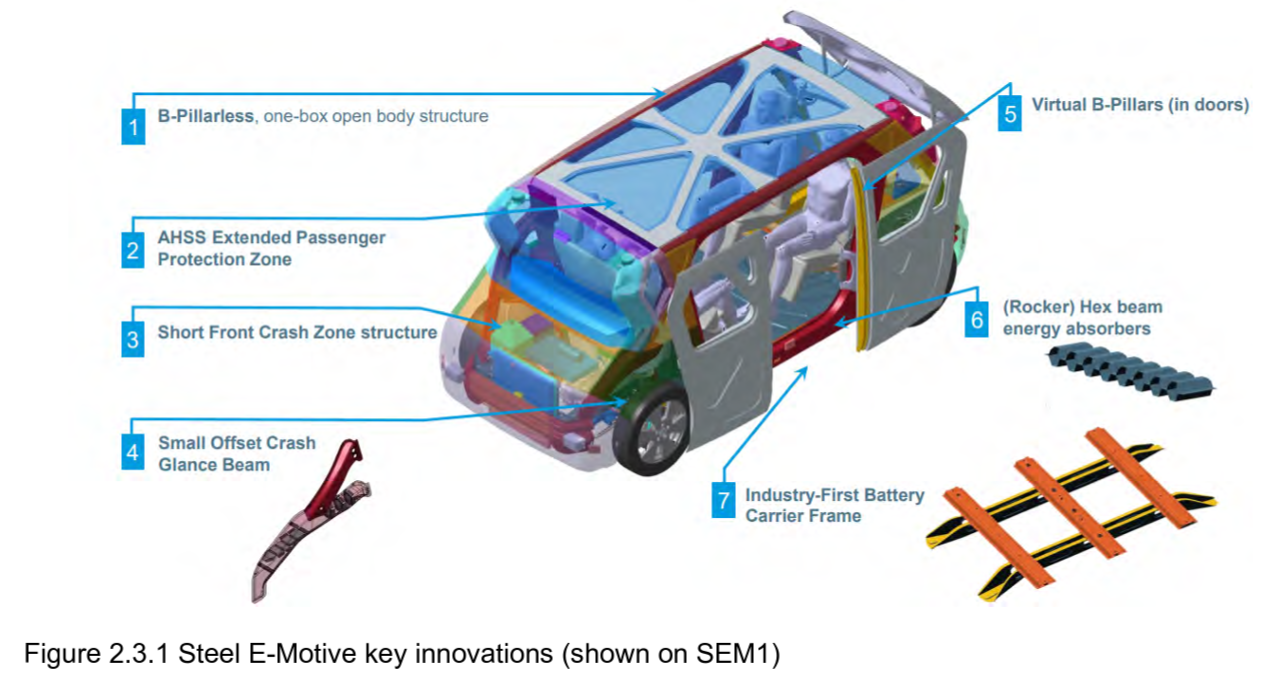

Steel E-Motive aims to provide new vehicle concept designs that demonstrate how Advanced High Strength Steels (AHSS) can help deliver cost-effective, sustainable, and safe transportation in the future. More specifically, the goal is to develop the world’s first fully autonomous, electric vehicle body structure concept for ride-sharing.

Two vehicle design concepts were engineered and unveiled in 2023, the SEM1 and SEM2. Both vehicles are specifically engineered to be SAE Level 5 autonomous.

SEM1 is a compact, four-passenger vehicle intended for short, city-type journeys. It has a 75 kWh battery electric propulsion system with a front axle and single-speed electric motor.

SEM2 is a larger version of SEM1 and seats up to six passengers. Its use is for longer, higher-capacity journeys such as city-to-city, and it has a larger 96 kWh battery with front and rear electric motors.

This year, Steel E-Motive released an engineering report and two microstudies on front and side crash body structure concepts that meet global crash standards.

WorldAutoSteel previously told Repairer Driven News that it provides Steel E-Motive results, data, and CAD models for free to automotive manufacturers and others to aid in producing a new generation of efficient, economic, and sustainable vehicles for a safer, zero-emission transportation future.

According to the 2025 Steel E-Motive engineering report, SEM1 and SEM2 can be assembled in an existing automotive manufacturing plant with conventional joining equipment. Excluding the laser welding blank process, the vehicle components are joined with resistance spot welding, laser welding, and adhesive bonding.

AHSS, which Steel E-Motive notes have been successfully resistance welded in automotive assembly lines for several years, requires higher clamping forces due to their extremely high strengths. That means tools must be updated, especially in Tier 1 and older assembly shops, to complete AHSS joining, according to the report.

“Typical weld parameters apply to these materials, but must be more closely controlled, as process variation may impact joint strength and functional performance.

“With AHSS, even full interfacial failures may exhibit high strength, although it may sometimes be challenging to differentiate between an interfacial failure and a ‘stuck’ weld condition (which refers to an unfused bond of unacceptable strength). To improve nugget failure modes with AHSS, the hard martensite must be softened. A simple and effective approach to accomplishing this is to add a temper cycle at the end of the weld, something that can easily be added at the end of the spot-welding cycle.”

Proper quench time is also important before tempering to allow for the formation of martensite, a hard and brittle solid solution of carbon in iron.

“Depending on how hardenable the steel being welded is, other approaches that slow cooling rates may be helpful,” the report states. “These approaches include current pulsing, current sloping, longer weld times, and short hold times. The unique physical characteristics of Advanced High Strength Steels (AHSS) present some challenges to welding and bonding processes. AHSS differ from mild steels by chemical composition and microstructure.”

According to the report, one of the advantages of the resistance spot welding is clamping material together via the electrode force applied during the process. When welding AHSS, higher forces are generally required because a lot of the force is used to push the parts together in addition to the force that’s required for welding.

Another method, laser welding, is increasingly used in more vehicle applications due to inherent weld strength, adaptability to complex weld geometries, and lower part distortion.

For example, during a session of the 2024 Society of Collision Repair Specialists (SCRS) OEM Collision Repair Technology Summit, Dean Brennan, IPG Photonics sales manager, shared that the 2022 Honda Civic incorporates a laser-brazed roof, extending that technique to the OEM’s entry-level vehicles, and uses a greater amount of high-strength steel (HSS) and aluminum to save weight.

Brennan said OEMs are also using laser welders to repair cars while still on the line, and collision repairers could save a lot of time using a laser welder on EVs because they wouldn’t have to worry about the batteries.

The Steel E-Motive report states that laser welding is often used for AHSS lap (overlap) joints using different parameters compared to seam butt joint configurations.

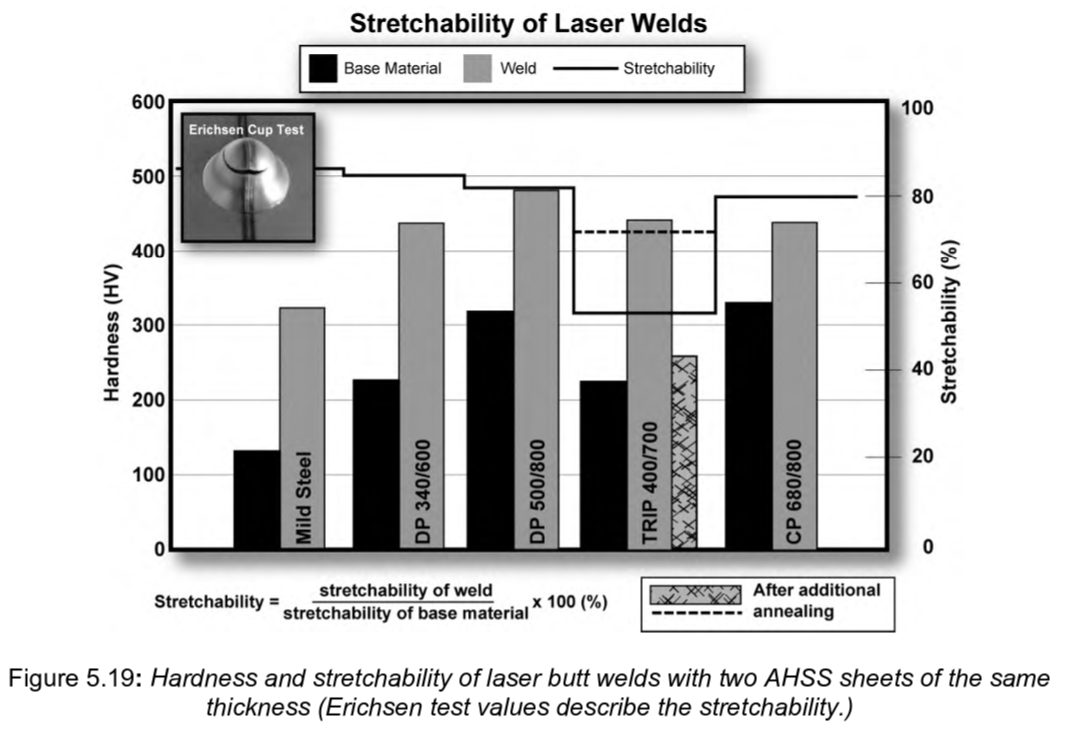

“Lap joints tend to provide a larger process window, which can compensate for some of the manufacturing difficulties with AHSS, including springback and part distortion,” the report states. “The hardness of the laser welds for AHSS is higher than for mild steels. However, good stretchability ratios in the Erichsen test can still be achieved when the difference in hardness between weld metal and base metal is only slightly higher for AHSS compared to mild steels.”

As for adhesive joining, the report states that the method offers the major advantage of joining a wide array of materials. However, it’s limited by joint strength and applicable service conditions.

“Many of the fundamentals are similar to brazing and soldering, in particular the need for wetting and capillary action, and overlapping joint designs that rely on joint area for strength,” the report says. “Adhesives are categorized as thermosetting or thermoplastic… Joining of AHSS with adhesive bonding is a good method to improve stiffness and fatigue strength in comparison to other joining methods (spot welding, mechanical joining, arc welding, and laser welding). If higher joint strengths are needed, the overlapped area may be enlarged.”

Images

Featured image: SEM1 concept cars (Provided by WorldAutoSteel)

Chart and diagram provided by WorldAutoSteel