UPDATE: Collision Advice: Responses to FCA auto body repair questions

By onAnnouncements | Business Practices | Education | Repair Operations | Technology

Editor’s note: Collision Advice, asTech and FCA in March offered auto body shops tips and highlights for navigating FCA’s Tech Authority OEM repair procedures website. Last month, Collision Advice reported it received a slew of questions related to the webinar’s subject matter, and it compiled the most common of these and the answers into a Q&A sent to webinar attendees. CEO Mike Anderson allowed us to share it here (minor edits) for the broader industry’s benefit. See the FCA webinar and similar Collision Advice presentations on Toyota and Nissan’s OEM procedures sites here.

Questino: Where can I find information on disabling and initializing OnStar for FCA vehicles? What is the process?

Answer: FCA US LLC (FCA) does not have OnStar, OnStar is the infotainment brand of GM.

Q: Is FCA going to update the Welding and Bonding manual on the Mopar Repair Connection website?

A: The manual will be reviewed and potentially consolidated. Some information is vehicle specific and will be in the collision repair manuals. Refer to the collision repair manuals for vehicle specific information relative to the documented application area.

Q: Does FCA publish a position statement regarding kinked steel and how to handle?

A: FCA states within their OEM repair procedures that any kinked steel must be replaced. I-CAR also states the same information. There is not a position statement. It is within the OEM repair procedures.

Q: On the value line coolers, what is the warranty?

A: It is the same warranty as the OEM standard cooler.

Q: What is the lag time on Connectors?

A: Historically connectors are shipped within two or three days after order.

Q: Is a Tech Authority subscription reduced or free for certified repair centers?

A: Currently, the fee is reduced to $300 for FCA Certified Shops.

Q: Is Tech Authority included in your yearly fees if you become a certified repair center?

A: No, currently there is no included Tech Authority with FCA certification. However there is a reduced fee for certified shops of $300 per year.

Q: How can you tell if a part is Magnesium?

A: Structure identification maps can be found in Tech Authority. The maps are also color code to show magnesium parts along with others. Tech Authority also includes diagrams for other combustible materials, like NVH foams.

Q: Does FCA have a position statement on flat panel sealing hemmed parts? For example, replacement hood panels and doors. When we receive them the OEM hoods come without any sealant. It is my understanding that we have to replace, but is there documentation on this process?

A: FCA has a stated sealing procedure. In Tech Authority, search for seam sealer or corrosion protection, and the results will show where FCA applies Seam Sealer specific to the hood. Keep in mind, labor times for seam sealing a hood is NOT included in the CCC estimating platform, but is included with Mitchell and Audatex labor times in their estimating platforms.

Q: Regarding the use of OEM Standard Procedures and OEM Position Statements, do any of these websites hold more credibility than another? What is the best to use when working with insurance partners?

A: We recommend all parties to reference the FCA repair procedures as the first point of reference for safe and proper repair instructions.

Q: Why can’t magnesium be repaired? Is it just because it creates a combustible material hazard?

A: Do not repair magnesium with any mechanical sanding or grinding tool. It is highly flammable and combustible. High speed sanding or grinding can create friction and cause the component and/or material to ignite. It is also a brittle substrate and doesn’t respond well to current repair methods.

Q: Due to the magnesium inner structure on many of the FCA gates, is it recommended to use an LKQ gate of same color to avoid any repair to the inner structure during a refinish procedure?

A: We advise to not utilize any salvage gates as there is no way to ensure the structural integrity of the part. However, keep in mind, that you can sand magnesium for refinish purposes by scuffing with a scuff pad or using sand paper, but cannot utilize a mechanical sander.

Q: Can you section a quarter panel without a backer using MIG brazing?

A: No, the proper repair procedure is to use a backer.

Q: Is Tech Authority and Tech Connect the same thing?

A: The content of both sites is identical. Tech Connect is the repository of FCA Repair Procedures for FCA Franchise Dealers and Tech Authority is the identical repository of FCA Repair Procedures those third party entities can gain access to by purchasing a subscription.

Q: Is there a quick search for one-time use parts, like airbag bolts, suspension bolts, and trim pieces?

A: Currently, there is no quick reference. Within the FCA Repair Procedures one-time use parts are identified by the term “Remove and Discard”.

Q: How can a shop perform a destructive test weld? Is there a certain strain the welds should withstand?

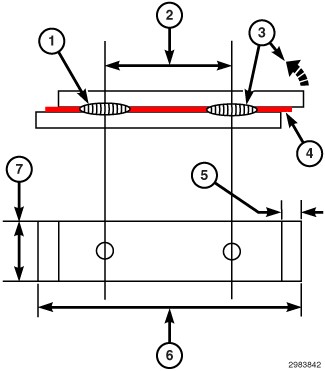

A: After the shop has successfully completed a weld coupon, position the weld coupon vertically and secure in a bench vise. Using pliers hold one piece of steel in place (4) and another to pull the joining metal down and away from the part (3) (Fig.1).

Figure 1

Next, pull past the initial spot weld, then inspect the weld zone for proper weld penetration.

- If there is metal tear out around the spot weld and a hole present in one of the joining pieces of metal, the weld meets FCA requirements.

- If there is weld burn through or partial or no metal tear out the weld has failed FCA requirements.

NOTE: Periodically check the electrodes tips to determine whether the faces have been contaminated, damaged or increased in size. If any of these conditions have occurred, replace or re-face the electrode tips per equipment manufacturer recommendations.

Q: Shouldn’t we cut weld panels from the old replacement part for test panels?

A: Cutting scrap panels may not yield a positive result due to potential metallurgy effects from the collision impact.

Q: Where can we find weld coupons?

A: FCA does not currently have weld coupons.

Q: When doing a destructive weld test, is it important to get the right grade of steel as they react differently with MIG / MAG welding?

A: Yes, the correct grade of steel is essential to ensure it mimics the repair area.

Q: In a rail replacement, should you wand epoxy and then wax?

A: Yes, you should utilize epoxy primer prior to applying any seam sealer on the exterior, as well as to any areas where the OEM primer has been removed due to sanding and welding. Also, apply cavity wax on the inner structure after welds are completed.

Q: Why can’t we use weld through primer and what should be used?

A: FCA Engineering does not recommend the usage of weld thru primer. To restore corrosion protection after the weld process, apply 2 coats of cavity wax to the backside of the weld area and after dressing the exterior weld surface apply an epoxy primer.

Q: Will FCA start supplying new bolts/fasteners needed for replacement of new panels, such as aluminum hoods and suspension components that are one-time use? It would be great to get these as a kit. This would help assure that repairs are being done properly and with the required fasteners.

A: Kitting the fasteners with the hoods is not feasible at this time.

Q: Does FCA have intentions to have any of their OEM repair procedures integrated into the estimating systems? Perhaps as footnotes?

A: FCA is working with Mitchell and CCC to integrate repair procedures in their products.

Q: Obviously, it is in all parties’ best interest to repair vehicles properly. I’m sure one of the main reasons for FCA to become more involved in the collision repair process is for their customer’s safety. However, I assume another is to protect the reputation of their brand. I believe studies have shown customers have switched vehicle manufacturers after a collision because of improper repairs. My question is, why is the cost to provide this information passed on to the shops and not provided for free by FCA?

A: FCA makes available to the Collision Industry a free site to access FCA repair procedures as PDF documents via MoparRepairConnection.com. For shops that want access to Repair Procedure search engines, frequently asked question documents, and videos showing proper repairs, FCA offers Tech Authority as a paid subscription site.

Q: Is there any model-specific training available on Tech Authority? Or through FCA?

A: FCA does not facilitate direct collision repair training. We partner with I-CAR to distribute new technology information and collision repair best practices.

Q: Does AsTech have access to the Tech Authority website to help calibrations when pre- and post-scanning FCA vehicles?

A: Yes, AsTech™ is currently a subscriber to FCA repair information and has access to all FCA technical repair updates.

Q: Is there a scan tool that is approved by all OEM manufacturers to scan their vehicles other than their own equipment?

A: FCA recognizes their tool, WiTech and the third party, AsTech™ as the approved scan solutions for FCA vehicles. For more information on this, please access OEM One Stop for the published FCA scanning position statement.

Q: Can you clarify the position statement regarding FCA scan tools? Sounds like you said, “Have to use either WiTech or AsTech”, but then right after said as long as the tool can scan the latest model. Which is it?

A: FCA only promotes the use of the WiTECH or AsTEch device, not an aftermarket scan tool that may not have the latest updates from FCA or may have limitations. For more information on this, please access OEM One Stop for the published FCA scanning position statement.

Q: Can AsTech do seat relearns, like in the third-row seat example? Can it do resets?

A: The calibration referred to during the FCA Tech Authority Webinar was the third-row seat calibration on the RU chassis Pacifica. This seat is fully automatic from fully reclined to Stow and Go. asTech can perform this calibration and the system does set DTCs. According to Tech Authority, the seat must be calibrated if the ECM for the seat has been repaired or the seat has been serviced. The seat also has two separate motors on for recline and one for stow, each must be calibrated for the system to operate as designed.

Q: When looking at the dimensions of the underbody, what are the tolerances on the measurements? For example, on engine cradles. Note: I’m looking at the free website.

A: There are no tolerances, it must be on location to the spec.

Q: What is the recommended procedure for clamping a FCA vehicle?

A: Always anchor at the underbody vehicle pinch weld flange.

Q: How far away should the keys be kept from hybrid vehicles?

A: Key FOBs should remain in a secured location, at least 6ft from the vehicle location to prevent inadvertent passive entry functions from occurring when repairing the vehicle. The remote start function can be activated from the key FOB at distances greater than 100 ft. It is always a best practice to disconnect the 12v battery and PHEV battery main disconnect prior to performing any repairs.

Q: If a calibration isn’t performed, will this show up in a pre/post scan saying that this procedure needs to be performed?

A: A diagnostic trouble code (DTC) would need to be set for this to populate on the scan report. For instance, if an electronic power steering rack required replacement and a DTC was not set, then it would not be prevalent that a calibration is required. When the customer receives delivery of their vehicle, a DTC will set when they begin driving the vehicle. At that time, the scan tool will detect the need for a calibration.

The new DT chassis Ram truck moved the Blind spot system to the tail lamp. To calibrate the system, you need to drive the vehicle over 13 mph (20 kph) on a straight path for longer than one minute. Once this criterion is met, both mirror Light Emitting Diodes (LED)(s) will go from active to off and the DTC will transition to stored. The DTC can then be cleared.

If the shop doesn’t drive the vehicle greater than 13 mph in the shop with the lamp removed very likely there will be no DTC, as the system is not active.

Some new modules come from FCA in “plant mode”, systems like air suspension, blind spot and active air dam. Drive cycles with certain MPH and time must be achieved to activate them. In the case of a BSM system, a shop would only catch this by researching how to R&I the taillamp.

Q: Is there a statement regarding 4-stage paint?

A: FCA currently does not have any 4-stage paint codes on any of their vehicles.

Q: Is there a statement regarding 3-stage paint?

A: FCA does not have a statement on 3-stage paint. However, FCA does identify in Tech Authority which paint codes are a Pearl or 3-stage.

Q: When the repair procedures say no heat when straightening, does that mean you can’t weld a pin to the frame rail to pull it?

A: Do not weld adjacent to areas where the replacement panel will be joined to the vehicle. Only weld pegs in locations that will be replaced and are greater than 6 inches away from the replacement area to prevent an adverse heat affected zone.

More information:

“Learn to Research; Research to Learn (Using FCA’s Tech Authority)”

Collision Advice and FCA, March 23, 2018

Images:

The FCA logo appears on the Tipton Transmission Plant. (Provided by FCA)

The magnesium (yellow) and aluminum (green) liftgate of the 2017 Chrysler Pacifica. (John Huetter/Repairer Driven News)

A FCA US Toledo Supplier Park employee fills the fluids of the last Jeep Wrangler JK on April 27, 2018. FCA will retool the facility for a next-generation Jeep truck. (Provided by FCA)