Collision Hub, NCS: Jobber, shop should look beyond paint discount for profit

By onBusiness Practices | Education | Market Trends | Repair Operations

“You eat dollars,” not a percentage, NCS continuous improvement Executive Director Tim Briggs told Collision Hub on an April 25 “Repair University” that might leave auto body shops rethinking how to use their jobbers.

The episode presented “five core pillars” collision repairers seek from distributors, Collision Hub CEO Kristen Felder said. These were derived from a prior survey of 700 collision repairers, she said.

“No one touches the shop more frequently than the jobber does,” she said. Though the show featured NCS, the episode sought to instruct shops in how better to use whichever jobber they had, according to Felder.

Shops wanted training, fulfillment, profitability, color and inventory control assistance from their distributor, Felder said.

However, some of these pillars seemed to blur and end up at the same place: a better balance sheet.

Go beyond paint discount

The show encouraged body shops to look beyond what kind of a discount on paint their jobber could provide and examine other profitability.

Briggs said every repairer declares, “‘I just want a big discount,'” and insists they don’t care about service. But if the distributor can grow a larger aspect of the shop’s business 10 percent rather than assist 10 percent with a smaller part of the balance sheet, than the shop is better off, he said.

Jobbers “honestly” traditionally haven’t done well in this regard, and their failure to differentiate themselves provides no reason for a shop to, Briggs said. (Besides, another jobber can just undercut the first jobber’s discount, NCS Logic ICS sales director Sean Lapham pointed out.)

It might seem like a 20 percent discount on paint meant 20 percent profit, Briggs said. However, he said NCS will see MSOs in which each of the chain’s dozens of shops deliver individual results ranging from a 10 percent material loss to a 60 percent profit. People and process matter, he said.

“You gotta decide where you want to make your money,” Briggs said.

The show provided examples of how a repairer or jobber could increase profitability without relying on the paint discount. Gross is nice, but net could be greater on other items, and jobber help on those matters could yield a larger benefit, Felder said.

Paint and liquids were a “small portion” of a repair compared to $300-$500 worth of materials “not liquid” going onto a vehicle, Felder said.

These are items that for a repairer, “we feel good with the paint discount that we miss on the back end,” Felder said.

A shop failing to itemize these would leave much on the table, she said.

Briggs called the average repair order “sad.” At an average repair of $3,000 and a net of 10 percent, the shop only made $300, he said. If the shop wastes $150 of it because it can’t use paint cups correctly, “what’s the point?” he said.

Organization

Distributors can help profitability by organizing a shop’s items, both on an overall system and during deliveries, according to the show.

One low-hanging fruit for a jobber and shop is simply to merely put items away. Briggs said he often walks through shops, and it’s “almost like your laundry on the floor.” Repairers will just pull items out of a box left on the ground.

Lapham recalled once bringing in a box of supplies to a repairer that said the jobber neglected to deliver it. The product had in fact been dropped off — that box was already sitting in the shop, Lapham pointed out.

“‘I couldn’t find it,'” the shop said.

A jobber stocking supplies can prevent situations in which a shop employee building a parts cart of materials for a repair can’t find an item, according to Felder. Instead of stopping the process, they just say, “‘No, never mind'” and continue, she said.

Even a repairer with better organizational skills might realize a benefit from a jobber handling the stocking, according to Felder. Having a shop employee stock shelves means they’re not doing something more profitable for the business, she said.

Lapham also said that when he walks through shops, “I just look for waste.” He said a situation in which every technician has their own cabinet results in a situation like a teenage house party trying to clean up when the parents get home: Everything gets shoved into a closet.

Owners should walk around a shop and look for waste and redundancy, he said.

He said a shop should break down what each department actually needs, recalling a company that had more than 2,000 SKUs of supplies across its five locations. NCS got it down to an approved product list of just 215 part numbers.

Setting up an approved product list allows repairers to track inventory and keeps things consistent when technicians move from shop to shop.

Shops should also buy supplies based upon OEM requirements, Felder said.

“Every technician has a favorite,” Felder said. She recalled listening to a client boasting about their inventory control yet encountering prohibited copper weld-through primer in the first technician’s stall.

Please go

But even a helpful jobber can overstay their welcome. Another point of waste might be the jobber merely hanging around a shop too long, according to Felder.

“I’m thinking, ‘We just spent 30 minutes not working on a car,'” Felder said of encountering such situations. The ideal is to make the delivery, help solve a problem if it exists, and leave, she said.

Lapham said NCS shoots for an average of 12 minutes at a facility. The average salesman handles eight stops, so “get in, get out” is the mantra and means NCS has time to offer more services, Briggs said.

Other ideas

A few other interesting observations from the show:

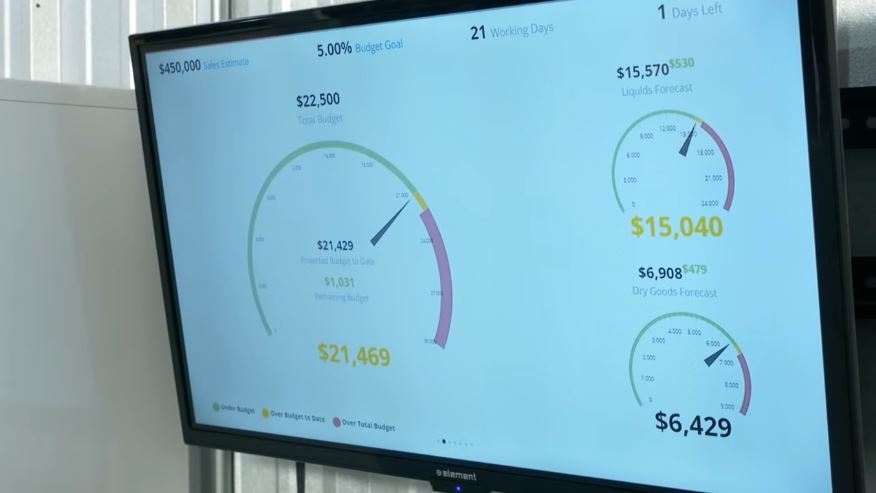

• Keeping track of numbers daily can be important to preserving sufficient cash flow.

Lapham recalled in the past taking tallies of total sales, material sales, repair order count and finish ours and cranking out a report. But by the time it was done, the client was halfway through the next month and already too far in the red to take successful action, he said.

Now, live data is possible, and a shop can nip an issue in the bud immediately, according to Lapham.

• Correcting mistakes quickly is important. If a shop has to return something, a repairer doesn’t want to wait a few weeks for credit, Felder said.

“Give me my cash flow,” Felder said. Collision repair is “cash flow-dependent,” she said.

• Lapham also put in a plug for the idea of a parts cart rather than constantly walking to a supply closet. If a repairer isn’t touching the car, they’re not making money, he said.

“One of the waste is movement,” he said.

• Little gains also can help a shop tremendously. $100 a day across 21 working days a month is $2,100, Lapham noted at one point during the show.

More information:

“Repair University: Getting The Most From Your Jobber Or Distributor”

Collision Hub, April 25, 2019

Images:

An April 25, 2019, “Repair University” from Collision Hub featuring NCS examined benefits a jobber could bring to a shop besides a paint discount. (Screenshot from Collision Hub)

NCS in an April 15, 2019, Collision Hub “Repair University” mentioned how live financial data could help a shop get on top of a profitability issue quickly. (Screenshot from Collision Hub video)