Breaking down the macro technology trends coming to collision repair

By onAssociations | Business Practices | Education | Market Trends | Repair Operations | Technology

A number of technological megatrends are about to hit the collision industry, and it can be difficult to keep up with them all or understand the concepts behind the buzzwords.

Fortunately, VeriFacts “Internet of Things” Vice President Fred Iantorno gave the industry and stakeholders a helpful rundown of many of them on this month’s VeriFacts Guild 21 webinar.

We’ve covered and explained many of these in past articles, but such stories tend to focus to a single technology each. Thus, we felt recapping Iantorno’s talk would serve as a useful primer for shops by presenting all the tech in one place.

Iantorno is the former longtime leader of collision industry software standards organization CIECA and has spent 37 years in information technology.

As moderator George Avery characterized it, these are technologies that aren’t necessarily happening today, but shops still need to think about them.

Iantorno said these concepts used to be called or are still referred to as “emerging technologies,” but that’s inaccurate.

“They’re not emerging anymore,” Iantorno said. Some might not have arrived yet in the collision industry, but they are present in other industries, he said.

Iantorno said you don’t need an “absolute working knowledge” of the technology to appreciate it. As business professionals, it would suffice to be aware of the trends and embrace change, he said.

If you don’t embrace it, “it will run over you.” If you do, “it’s fun. It can be fun,” Iantorno said.

5G

Iantorno said 5G wireless technology is much more than “a faster 4G.”

5G does offer greater speed, but also lower latency and is “more responsive,” according to Iantorno. The message reaches the target faster, and the response returns faster.

5G also offers the ability to connect many more devices to the Internet. The number of connected devices already exceeds the number of humans on the planet, according to Iantorno. It’s been predicted that someday there’ll be 1,000 connected devices for every human on Earth.

IoT (“Internet of Things”) and connected devices

Avery listed devices like a washer, dryer and thermostat being connected to the Internet, and Iantorno said the reality was all of that “and more.”

He recalled recalled buying an oven and being surprised when the vendor asked if he wanted one with Internet. (Iantorno declined.)

This is all part of the concept known as the “Internet of Things,” in which everything is connected online to everything else, according to Iantorno. Your phone can communicate with everything.

Iantorno noted that Internet devices existed in both consumer and industrial formats. They used to be expensive, but today have fallen below $50, he said. He gave the example of connected light bulbs used to cost $35-$40; today, they’re $5-$10 or less.

The cost to connect a device has dropped “tremendously,” he said.

Iantorno said his whole home is automated (except for the oven, apparently) and one of the last devices to be so equipped was the garage door opener. He can check with a smartphone remotely to see if he remembered to shut it, he said.

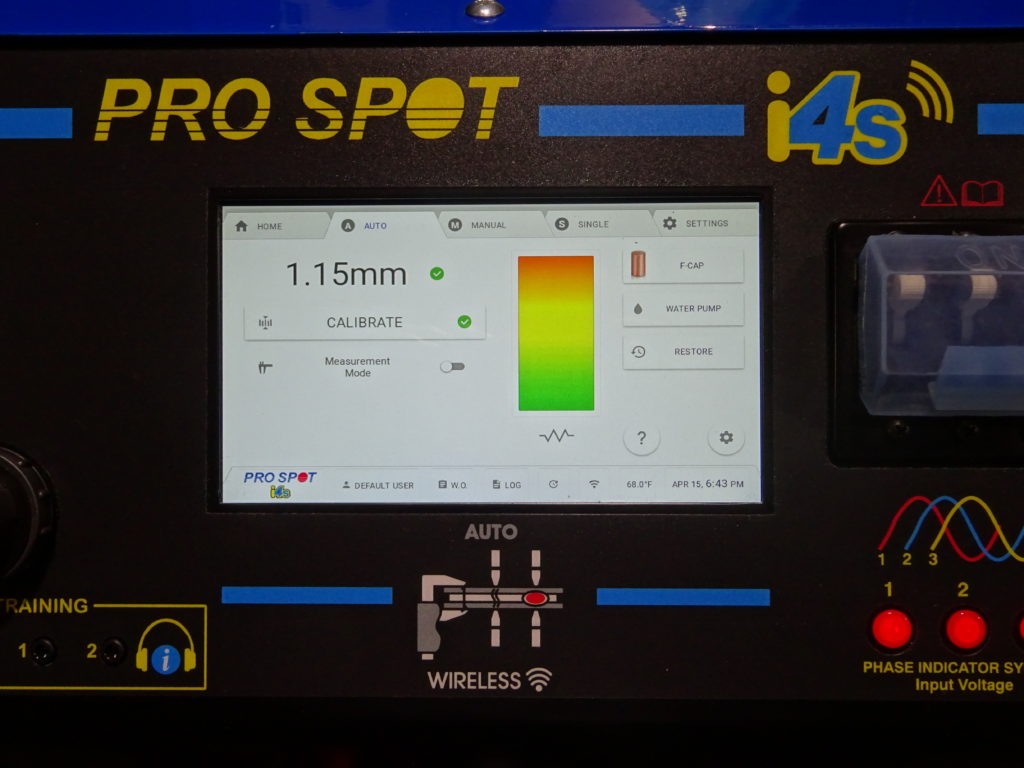

In collision repair, all of the latest versions of tools and equipment either have a “full computer” or an “edge computing device,” according to Iantorno. If you have any of that late-model gear, you’re already on your way to a connected auto body shop “whether you know it or not,” he said.

IoT could also involve a vehicle reporting a loss, or simply situations like Iantorno’s daughter able to see that his son-in-law won’t be home for two hours based on his location.

Wi-Fi and coverage

Of course, all of this “smart” technology can’t work without an active Internet connection. An informal poll of the audience asked if they had solid Wi-Fi in every space in their facility. 52 percent of the audience said they did, another 44 percent said no, and 4 percent didn’t know.

“That’s about right, I think,” Iantorno said.

Iantorno said cloud-based apps need connectivity, be it Wi-Fi, 5G, etc., and repairers therefore should have a reliable system. Otherwise, the shop is constantly having to interrupt work to go to a device which can offer that connectivity or even print out a hard copy of the information, he said.

“It’s inefficient,” Iantorno said.

Good connectivity was “a very important thing” for a shop given the number of cloud-based applications, he said.

Edge computing

Iantorno said edge computing involved processing closer to the source device.

Right now, with cloud technology, the data from your computer or connected device must travel to the cloud to be processed and then return, he said. But with edge computing, the device can talk to a local edge computer — which might be just a “small little box,” Iantorno said.

With billions of connected devices poised to appear, either the cloud needs a massive amount of computing power, or the computing must occur at a lower level, Iantorno said.

Right now, the cloud “looks and sounds limitless,” but moving the processing to the edge lets the system and artificial intelligences operate faster, Iantorno said.

Greater speed and lower latency occur with edge computing, he said.

Learn more from Iantorno at IDEAS Collide

Learn more at SEMA about what a connected collision repair facility could mean at “Collision Shops in the Connected Age” featuring Fred Iantorno of VeriFacts. The talk is one of the 10-minute presentations during SCRS’ rapid-fire, TED-esque IDEAS Collide Showcase running 10:30 a.m.-12:30 p.m. Friday, Nov. 8. IDEAS Collide is the finale of the Society of Collision Repair Specialists Repairer Driven Education Series running Nov. 4-8. Register here for individual courses or the series pass package deal, which includes the entire week of classes, all three parts of the OEM Summit, IDEAS Collide and the Nov. 7 Sky Villa afterparty.

AI (artificial intelligence) and ML (machine learning)

Iantorno said artificial intelligence is creeping into almost everything in life. He gave the example of his thermostat, which knows when Iantorno likes to the adjust the temperature. The device asks him if he’d like it to just do it.

“It has learned my habits,” Iantorno said.

This is known as machine learning, or sometimes “ML,” Iantorno said.

Artificial intelligence will be part of any disruptive technology going forward, and it was “all around us today,” Iantorno said.

Using software to handle photo estimating or intelligent first notice of loss are two AI examples from the collision industry, according to Iantorno.

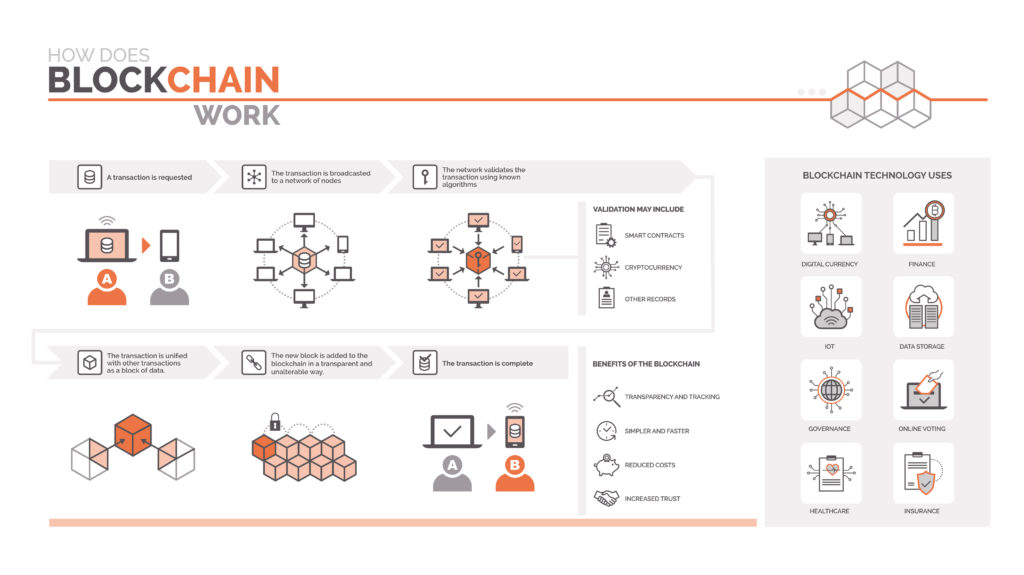

Blockchain

Most people have heard about blockchain because of bitcoin, but that’s merely one application, according to Iantorno.

It’s also used by manufacturers to improve the supply chain and has a home in health care, electric utilities and financial sectors, he said.

“It’s a very good thing,” Iantorno replied when Avery asked if blockchain was a “good thing.”

The system works by giving every party a copy of the entire ledger, Iantorno said. Any changes made by one party are visible to all, providing “full transparency,” he said.

One party on the chain — for example a parts supplier — might not need all of its information contained there, and that data can be hidden from them, Iantorno said. However, that hypothetical supplier will still receive a notice whenever something has changed.

Iantorno described a scenario where everything in a collision repair claim could be viewed on the chain: the first notice of loss, estimate, repair order, parts order, and every other step through the final settlement.

Asked about the status of blockchain as it related to the collision sector, Iantorno said some implementations existed, though he said he didn’t want to call them pilots.

Iantorno said some examples exist in the subrogation and financial spaces in which insurers play, and some applications exist on the “parts side,” but he wasn’t sure if the latter involved parts relevant to the collision repair industry yet.

However, it’s likely in existence at any part manufacturer, Iantorno said.

VR (virtual reality) and AR (augmented reality)

In virtual reality, the viewer sees an object that’s not physically present, though it looks as though it is, according to Iantorno. This can be useful in a harsh environment or simulating equipment which is expensive to purchase for training purposes, he said.

Augmented reality involves a physical object with virtual 2-D or 3-D items overlaid on top of it, according to Iantorno. (A famous example is “Pokemon Go,” which shows virtual monsters hanging out in the real world when the real world is observed through a smartphone.)

Iantorno gave the example of needing to bolt something upon a vehicle. Augmented reality might bring up the torque specifications and the order the bolts need to be tightened in the user’s field of view.

Iantorno said he hadn’t seen the technology in a collision shop yet, but he thought it was coming.

Shortly after Iantorno’s Guild 21 talk, Mitchell on Tuesday announced it and Qualcomm had developed a proof-of-concept “Extended Reality” pair of “smart glasses” for collision repairers. (Qualcomm describes the phrase “Extended Reality” as encompassing both VR, AR, something called “Mixed Reality” and “everything in between.”) And a week prior, SCRS announced Tradiebot would present on AR during the SEMA IDEAS Collide Showcase.

Avery, now retired after a long time at State Farm, said it would probably make repairer-insurer interactions easier by showing what needed to be done in the glasses.

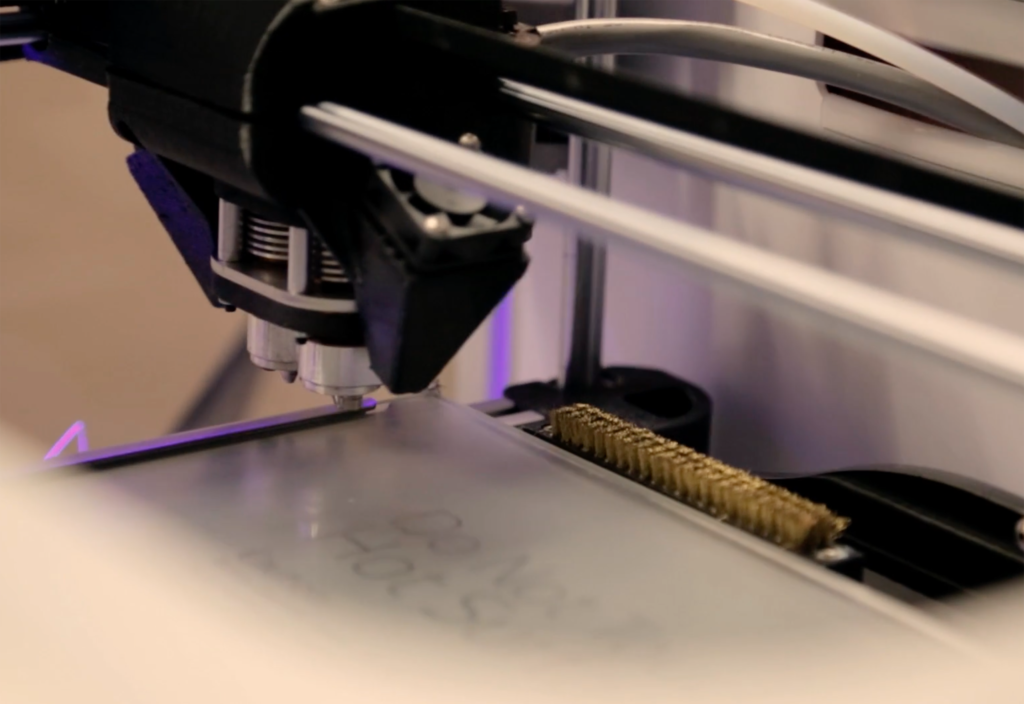

3D printing

Iantorno felt 3D printing had the potential to turn any business into a factory and was at an inflection point.

He said some MSOs have dabbled with the technology, printing items like clips. He said he’s used it himself, commissioning a 3-D printer to produce replacement clips for some old blinds.

Almost anything can be 3-D printed, and out of not just plastic but metal, he said. A setup can require $3,000 printer and expensive materials today, Iantorno said, but noted the technology was at the “tipping point” at which prices begin to fall.

He predicted we would see “a lot of this” in the future.

Avery asked if Iantoro thought the industry would see body shops staffing a 3D printer and producing their own parts.

Iantorno was skeptical, describing uncertainty of a 3D-printed safety part’s quality control as a concern.

“There’s the issue,” he said.

Iantorno said his “technology side” thought it was “‘cool,'” but his “personal side” was wary of putting such a part in his vehicle.

Robotics

Iantorno referenced an International Federation of Robotics projection that nearly 2.1 million new industrial robots will reach factories worldwide between 2018 and 2021. Fewer than 300,000 were delivered in 2016, according to the IFR.

Iantorno said a paint plant near Chicago runs nonstop. It’s manned by robots and one maintenance staffer per shift, he said.

But could that kind of controlled environment transfer to collision, Avery asked.

“Why not?” Iantorno said. If a robot could paint a car in the factory, why couldn’t one refinish a vehicle in a body shop, he asked. Perhaps not with today’s paint booth or layout, he allowed, but “why not?”

“… Somebody’s gonna imagine it,” he said.

Iantorno predicted “we’re gonna see it,” but perhaps not in the “next couple of years.” Like many of the topics discussed on the talk, a business needed to focus on the trend and determine how to take advantage of it and to “use creativity,” he said.

The next Guild 21 call will be 2 p.m. Oct. 10.

Images:

Some of the nation’s macro technology trends bear watching by the collision industry, according to VeriFacts Vice President Fred Iantorno. (cnythzl/iStock)

Collision Industry Electronic Commerce Association Executive Director Fred Iantorno speaks April 12, 2018, to the Collision Industry Conference about a CIC Wiki developed by the CIC Definitions Committee. (John Huetter/Repairer Driven News)

The Pro Spot i4s Smart Spot Welder features Wi-Fi connectivity. (John Huetter/Repairer Driven News)

One explanation of blockchain, the system used for bitcoin. (elenabs/iStock)One explanation of blockchain, the system used for bitcoin. (elenabs/iStock)

Service King is using 3-D printing for some minor bumper fascia repairs in what it calls “adaptive plastic repair.” (Screenshot from video provided by Service King)