Ford highlights new OEM procedures, video for bedside replacement on old F-150

By onAnnouncements | Repair Operations | Technology

Ford’s recently released On Target newsletter for the collision repair industry alerts collision repairers and insurers to a procedure change on the previous generation of the Ford F-150.

Ford discussed it in the context of announcing it posted two new free videos for body shops on Fordcrashparts.com. One of these films teaches repairers how to comply with the new OEM repair procedures for fixing a 2015-2020 F-150. The other video explains how to look up OEM procedures on www.motorcraftservice.com in the first place.

“The first video details the revised Ford-approved repair procedures now available on F-Series Bedside Replacement,” Ford wrote in the On Target. “In it, Ford Senior Damageability Engineer Gerry Bonanni details the steps involved in replacing the pickup box outer side panel on the aluminum F-150.”

Bonanni in the video says the instructions apply “from the 2015 model year forward.” However, it’s unclear if the procedures would apply beyond the end of the 2015 design generation, which concluded with the 2020 F-150. The 2021 F-150 starts an “all-new” generation and might be different structurally. You’ll have to check the OEM procedures — which you’d have to do anyway, for neither this article nor the Ford video would be a substitute for the official instructions.

The new instructions for Section 501-30, “Rear End Sheet Metal Repairs, Removal and Installation” date back to Sept. 14, 2020. They override the old OEM procedures — which themselves only date back to Sept. 12, 2019, suggesting they too represented a revision.

Bonanni in the video said that under the new 2020 instructions, a box outer replacement can be completed with blind rivets or MIG plug welds “or a combination of the two.” He said the F-150 also permits the option of using self-piercing rivets in the wheelhouse, but this is “not an option” for the Super Duty versions.

“The repair procedure for F-150 is changing, but for Super Duty, it remains the same,” Bonanni said.

According to the video, necessary equipment could include a 6.5 mm drill bit, a self-piercing rivet gun able to remove and install rivets, a belt sander, a blind rivet gun, a hot air gun, MIG/MAG welding equipment, locking pliers, Ford-approved metal bonding adhesive, seam sealer and flexible foam repair.

Bonanni calls the rivet bonding method “mostly blind rivets.”

The rivet bonding method includes adhesive, but only in four areas.

You’ll also need a welder. The video explains that 16 rivets between the stake pockets in the top rail will be hidden by the rail cap. “For the six fastener areas between the stake pockets and the pickup bed, you’ll use MIG plug welds for a clean appearance.”

No adhesive should exist between 0.25-0.5 inches of the connection points in the area between the pockets and bed, the video says.

If you’re MIG plug-welding the bedside under the alternative repair procedure option, you’ll leave the adhesive on the shelf altogether, according to the video.

“Do not use adhesive,” a narrator said in the video. “Otherwise, the weld joint will become contaminated.”

According to the narrator, Ford would rather shops use the MIG welding option. “MIG plug welds are preferred compared to the appearance of blind rivets,” the narrator states.

Bonanni said repairers can combine elements of both repairs under certain conditions to produce a “fast and efficient” fix which was still approved by Ford.

Bonanni said a rivet-bonding repairer could use MIG plug welds at the top of the box nearest the cab “to help the rail cap set flush.”

Conversely, a shop could introduce the 16 blind rivets into an otherwise MIG-welded repair “for the fastest repair,” for the rail cap molding would hide the fasteners, he said.

“However, you must MIG-plug-weld the six points … nearest the stake pockets inside the bed area,” Bonanni said. “Again, this helps create a clean appearance and a flush surface for the rail cap attachment.”

Or a shop could opt for self-piercing rivets to join the wheelhouse under either the riveting or welding methodologies. The original attachment sites can’t be used, though, according to Bonanni.

“It must be adjacent to the original location and match quantity,” Bonanni said. He also reminded repairers that Super Duty wheelhouses were off limits to this technique. “Aluminum Super Duty will never use self-piercing rivets in the wheelhouse opening”

Food for thought

The new Ford instructions are a reminder of the need to check OEM procedures fresh online before starting every repair, even a model-year combination you see frequently or just completed the previous day for a different customer.

Instructions could change at any time. The repair procedures printed out by a shop who delivered a 2015 F-150 with a fresh bedside to a customer on Sept. 13, 2020, or Sept. 11, 2019, would be obsolete for an identically damaged F-150 brought to the shop the next day. Without checking anew online, the shop would have no idea anything was different.

Instructions could also change for any model, not just the newest ones. On the procedure release date of Sept. 14, 2020, the 2015 F-150 was six years old, and it and the rest of the 2015-2020 design generation were about to officially become old news. The next-generation 2021 F-150 would reach dealers in two months. Yet Ford still cared enough to overhaul the bedside repair procedure for the older models.

The Ford video and On Target also serve as a reminder that Ford offers many resources to the collision industry for free. If you haven’t visited the FordCrashParts.com webpage, give it a look. The On Targets and a dozen videos are present there, as are Ford’s position statements, links to its official equipment and repair procedure websites, and information on approved paint, adhesive and glass.

More information:

“Ford Offers Collision Repair and Safety Tips in New Videos”

Ford On Target, April 2, 2021

Ford, April 2, 2021

Ford official OEM repair procedures

Images:

The 2019 Ford F-150 Limited bed is shown. (Provided by Ford)

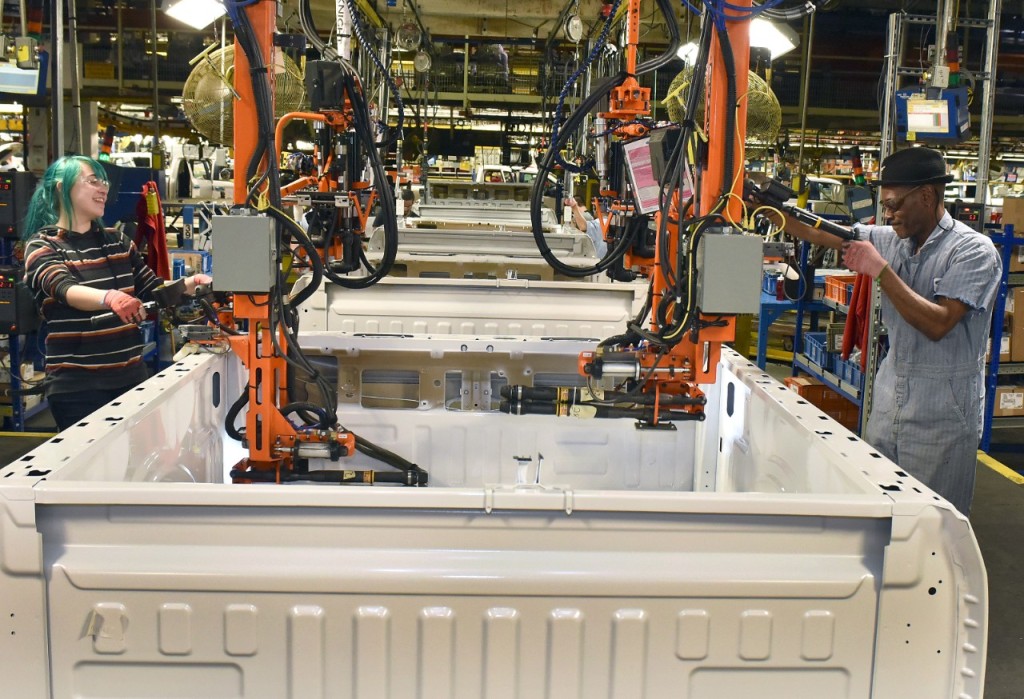

From left, Ford assembly line staff Denell Sadler and Levi Rouse work on the 2015 Ford F-150 in Claycomo, Mo. (Sam VarnHagen for Ford/Provided by Ford)

A Ford F-150 moves through the Ford Rouge complex Sept. 27, 2018. (Sam VarnHagen/Ford)