Swiss Federal Institute of Technology develops new sheet metal deformation test using semiconductor camera

By onTechnology

New research from Swiss Federal Institute of Technology demonstrates how a camera with a complementary metal oxide semiconductor (CMOS) can be used to determine the weakest fracture point of sheet metal with one test.

This gives repairers not only a glimpse of the amount of force varying materials can take in crashes to protect vehicle occupants but also how important it is to use the correct materials and follow OEM repair procedures to return vehicles to their pre-crash safety levels.

“Plane strain tension is one of the most critical loading conditions leading to ductile failure in forming and crash applications,” researchers wrote in the 10-page research paper. “Hence knowing the fracture strain and weakest orientation for this stress state is crucial for safe design.”

The experiments were performed on two aluminum alloys (AA7075 and AA6014) and two types of steel (DP1180 and CR4) of varying thicknesses between 0.5 to 2.5mm, which allowed for fracture strains of at least 0.8.

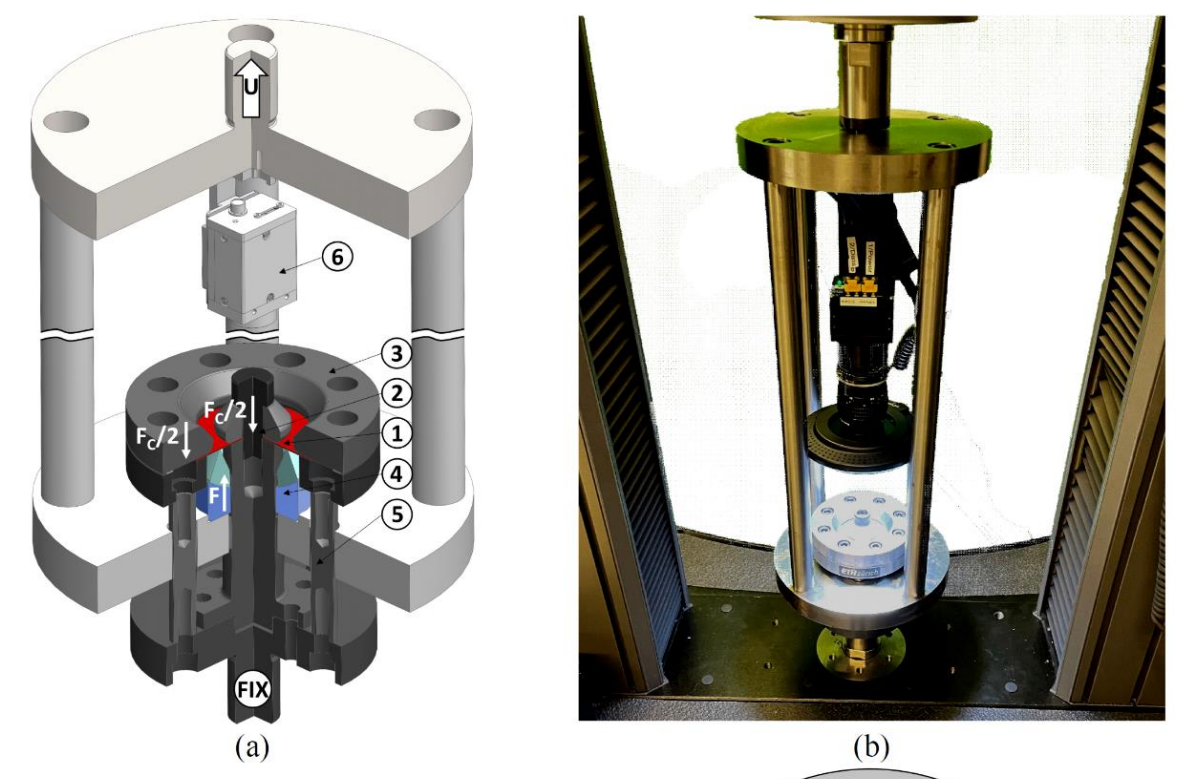

“The main idea revolves around a disk shaped sheet specimen clamped on the inside and outside being bent over an axisymmetric knife. To validate the novel experimental setup, four new sheet metals are tested with up to five repeats: 1.2mm thick aluminium alloy AA6014, 2mm thick aluminium alloy AA7075, 1mm

thick dual phase steel DP1180 and a 0.6mm thick deep drawing steel CR4.”

An axisymmetric V-bending experiment to find out how much strain is taken before the sheet metal starts to crack and then fractures. The test also determines the weakest orientation of sheet metal compared to how it holds up to strain tension.

Disc-shaped laser-cut sheet metal samples were clamped then bent over a tubular 54mm knife to conduct the tests and a single camera took images of the top surface of the samples throughout the duration.

“It allows for timely crack detection and digital image correlation-based strain measurements,” the paper states. “One of the most common in-plane experiments uses symmetrical notched tensile specimens… These specimens expose severe limitations in the strain field and thus stress state homogeneity, which is partially due to through-thickness necking.

“In addition, early onset of fracture might occur from the free edges in a tensile stress state, thereby leading to an underestimation of the fracture strain for plane strain tension.”

The one-and-done test is possible because multiple orientations can be tested at once versus the usual practice of one orientation per test in most plane strain tension fracture experiments.

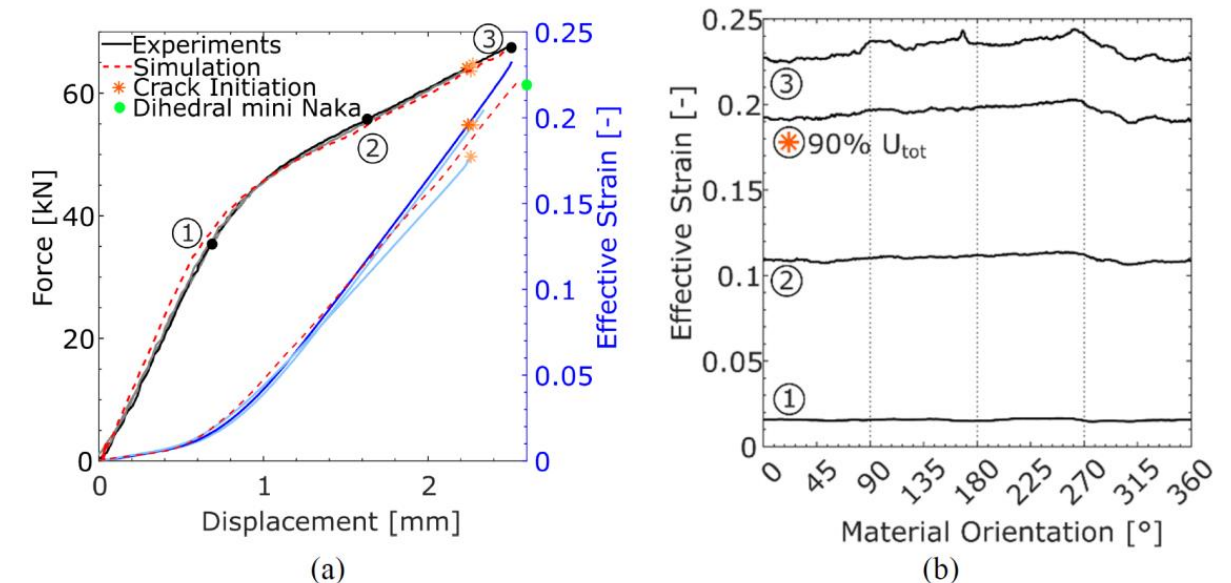

All of the tests had an initial elastic response up to 0.7 mm and 37 kilonewton (kN). One kN is equal to about 100 kilograms of load under Earth’s gravity. Following the initial response, the “plastic regime,” or how far the metal is deformed and left stretched, changed from 52kN/mm to 14kN/mm before a force maximum was reached.

As shown in the diagrams above, the first crack occurs on the sample surface at a strain between 0.18 and 0.2.

“At 90% of the total displacement, the first crack appears, which subsequently grows until the sample fails,” the paper states. “It is not possible to detect the crack from a change in the evolution of the effective strain or the force-displacement curve for this material. Only with optical methods the crack can be detected.”

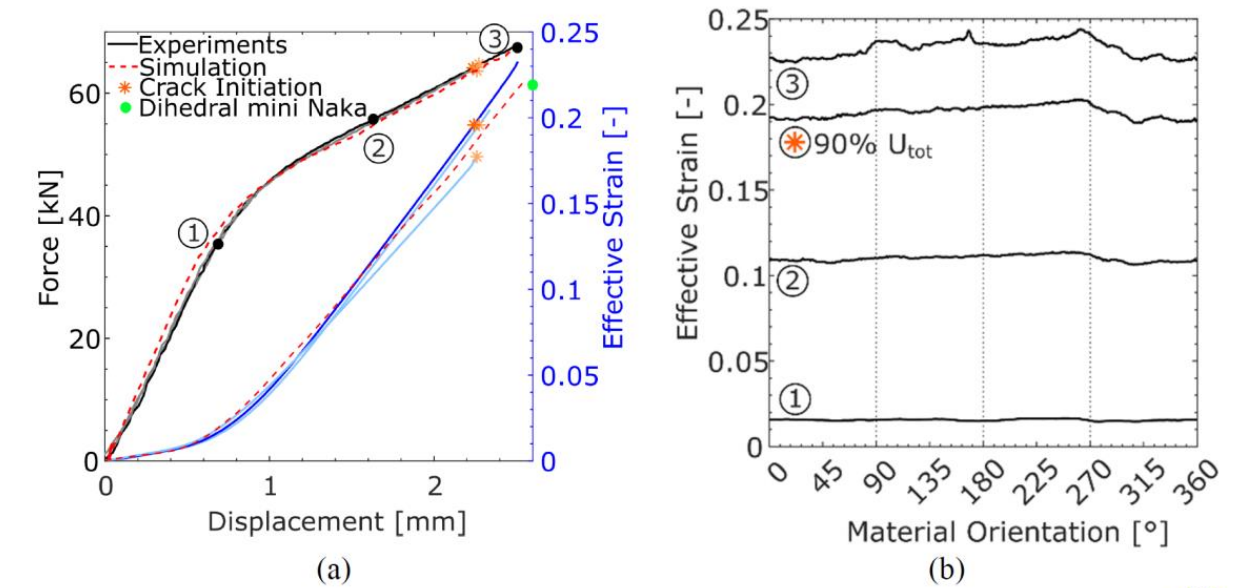

When the aluminum sheets were tested again, the initial onset of fracture, determined by visual inspection, occurred much earlier at a force level of about 72 kN and an effective strain of 0.26±0.01, as shown below.

For the 1.2mm aluminum AA6014 alloy, three repeats were performed. The force-displacement curves and the average effective strain were the same. After around 4kN, the force-displacement curve transitions into a plastic region with a slope of 8kN/mm and fracture was reached at 27.25±0.25kN, a displacement of 3.65±0.05mm, and an effective strain of 0.485±0.015. In other words, the first crack coincides with the force maximum.

The CR4 steel first cracked in all experiments at the force maximum of 31.6±0.3kN, a displacement of 4.8±0.08mm, and an average effective strain of 0.65±0.03.

Researchers said that CR4’s force at fracture was underestimated by 15%, but the estimation of the effective strain from the numerical simulations worked well for all materials and matched the fracture strain within less than 5% error.

Updates on the research can be found here.

Images

Featured image credit: baranozdemir/iStock

This image shows the setup of the experiments: (a) axisymmetric V-bending device and (b) picture of setup with sheet metal sample (red), inner clamping with center screw, outer clamping, knife-like circular punch (green), lower fixture (dark grey), camera with a ring light, and upper fixture (light grey). (Credit: Swiss Federal Institute of Technology)

All other images courtesy of Swiss Federal Institute of Technology