CCC, MOTOR to roll out ‘on-the-spot’ blending options beginning in October

By onCollision Repair | Repair Operations

MOTOR Information Systems (MOTOR) announced today it will remove the previous blend percentages, making a change to the Estimated Worktime Development Methodology for color blend of adjacent panels within the MOTOR Guide to Estimating (GTE).

The change is designed to account for variations in modern vehicle paint refinishing and will be made in October as part of the company’s standard GTE update schedule, MOTOR said in a news release.

“Throughout the first quarter of 2023, MOTOR reviewed information from multiple sources and has concluded that the current formula reflects an estimate for one particular scenario but does not necessarily reflect the many variations encountered with modern vehicle finishes and design,” said John McDonald, MOTOR’s product portfolio manager – content. “Given the variations among scenarios today, MOTOR believes that the Estimated Work Time Development methodology should defer to the judgment of an estimator or appraiser following an on-the-spot evaluation of the specific vehicle and refinish requirements in question.”

CCC Intelligent Solutions Product Management Vice President Mark Fincher told Repairer Driven News that in the current format, clicking the blend button in CCC ONE automatically conducts the computation based on whether two-stage or three-stage blending is selected.

“If it’s two-stage today, it just takes 50% of the refinished time and adds it to the estimate,” he said. “If it’s three-stage, it takes 70% and adds it to the estimate, which is MOTOR guidance today. With this updated guidance that MOTOR will be making, we’re going to enhance or change that functionality to support that.

“Now that MOTOR’s guidance does require an on-the-spot evaluation, users will have the option to be prompted, so they can input that blend time on a per-repairer basis based on the amount of work that needs to be done there. And secondly, we will allow users to input a default value for both two-stage and three-stage to be able to put in a default for their primary profile. Whether it’s a shop or an insurer, they can put in a default for that.”

Shops will also have the option to input additional profiles based on specific agreements by using a primary profile override. Roll out of the changes in CCC will begin in October in stages and wrap up by the end of the year. Rollout timing will be communicated to users.

“We do support MOTOR’s decision,” Fincher said. “We think this is a good outcome for the industry as a whole and accurately reflects the variation in the process as MOTOR described in the release.”

Fincher told RDN the change to CCC ONE will be significant as far as the behind-the-scenes work CCC will put into the platform.

“There’s one computational engine for estimating but it runs across multiple different user interfaces. We have a web version, we have a desktop version, we have a tablet version. The computational engine makes one update; all those user interfaces have to be changed as well.”

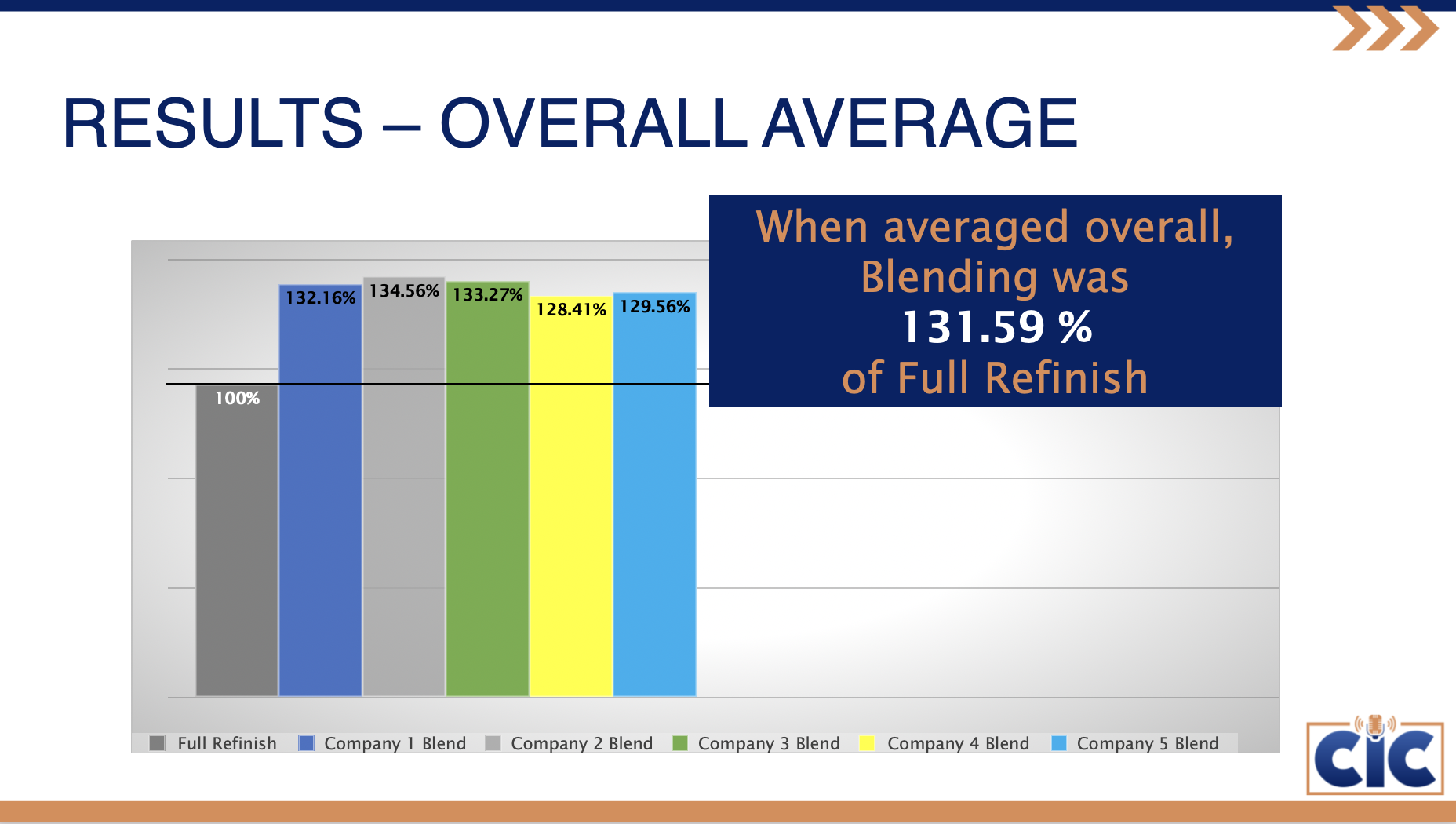

The Society of Collision Repair Specialists (SCRS) conducted a week-long, audited blend study last August in coordination with AkzoNobel Vehicle Refinishes, Axalta Coating Systems, BASF Automotive Refinish, PPG Industries, and Sherwin-Williams Automotive Finishes. The purpose was to study the comparative difference between the time necessary to perform a full refinish on an exterior panel, and the time needed to blend the same panel.

The estimating databases produced by CCC/MOTOR, Audatex, and Mitchell identify a formula for blending outer surfaces as 50%, or 0.5 per refinish hour, of the unique full refinish operation value they have developed on panels using 2-stage paint.

“The blend formulas have been a point of contention from the industry for many years, and MOTOR’s recognition of the variables that we’ve been communicating is an important and appreciated step,” SCRS Executive Director Aaron Schulenburg told RDN. “There is no logical way to look at the expectations that coincide with modern blending processes and the very rich and vibrant colors found on today’s vehicles, and not conclude that the preparation, application, and steps required are more involved than the 50% reduction that was established by all three companies over three decades ago.”

On Nov. 21, 2022, about three weeks after SCRS announced the blend study results during the Collision Industry Conference (CIC)’s fall meeting, CCC let the society know that “based on the recent database inquiries regarding MOTOR’s guidelines for blending adjacent panels, and in accordance with MOTOR’s standard operating procedures, MOTOR will conduct observational studies of the blend process. MOTOR will provide an update at the end of the first quarter of 2023.”

“Both organizations followed through with their commitment to both their process and the industry, and remained communicative with SCRS throughout the process as they worked through their own internal validation,” Schulenburg said. “This is a great example of an action that we had previously requested prior to the study, that is now only taking place because of the study results and the industry support that followed.

“That collaborative effort between AkzoNobel, Axalta, BASF, PPG, Sherwin-Williams, Ford, GFS, and DEKRA shifted the conversation from anecdotal to evidence-based. Those companies are all due a lot of credit for coming together to produce data that demonstrated the need. And CCC and MOTOR should be commended for being the first to commit to a fixed timeline to evaluate, responsibly concluding there was a need to change and remove the blend formula percentages, and committing to a timeline when the industry will see those changes take place.”

Neither Mitchell nor Audatex have publicly announced formal changes to their products yet, but SCRS told RDN they’re speaking directly with both, and that they have received a tremendous amount of feedback from the industry and their collision shop end-users.

As an interim workaround, Solera Industry Relations Vice President William Brower told SCRS via email that, “In the meantime, as discussed, our Solera estimating solution is the easiest one for users to adjust for edits like changes to the blend calculation.”

Solera provided an instruction document, published in March as a Database Enhancement Gateway (DEG) estimating tip. The document specifies how a business can use the Solera estimating solution to adjust for a change to the blend calculation.

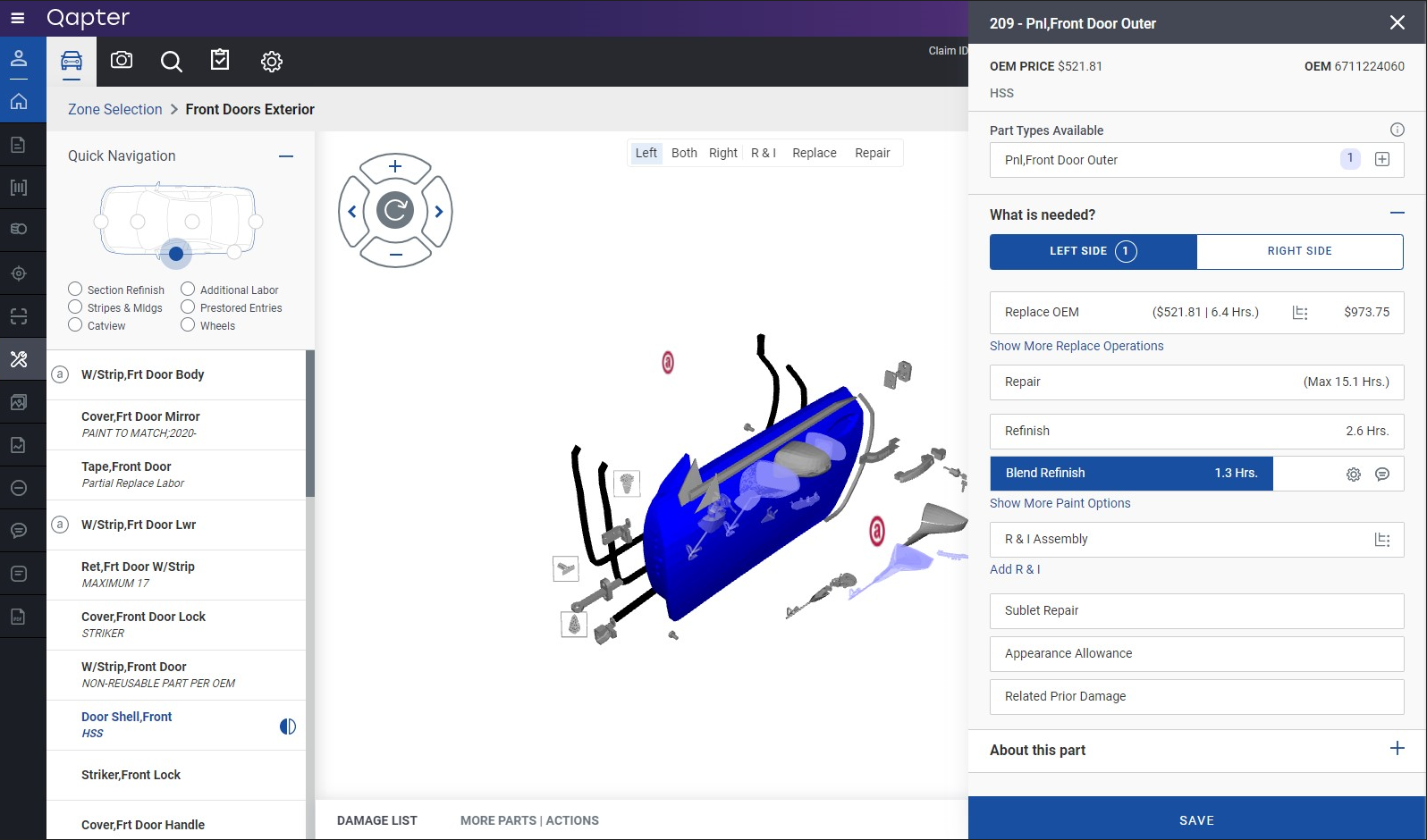

“See below the simple steps to adjusting the blend refinish hours,” the document states. “As you can see in the visual, a user can adjust the time in our Solera Qapter estimating solution when there is a need to adjust the automated blend hours. The slide out provides the full refinish time and the blend time so the user is aware of the full panel refinish times as they consider any adjustments for blend labor time.

Steps for adjusting blend refinish hours in Solera Qapter Estimating:

-

- Select the appropriate part (the slide out will appear)

- Select Blend Refinish

- Select the gear icon in the Blend Refinish bar

- Enter the user defined time in the Labor Hours box (highlighted in the visual below)

- Select Save & Close”

“As the other systems work through their internal processes and politics, it’s important to recognize that all three estimating products are guides — not fixed or rigid solutions, even if that is how they are sometimes used,” Schulenburg said. “The blend formulas are part of a guide, and the blend study documents clear, transparent information that can be a tool to substantiate the repair operations, processes, and comparative time spent between refinish and blending.”

Fincher said repairers have always been able to make changes in CCC’s system to modify labor time in blend refinish operations. When asked how repairers should document MOTOR’s decision in their estimates or repair plans, he said that’s up to each shop since preferences vary.

SCRS plans to present more on the blending topic during CIC’s July meeting in Indianapolis.

“It’s our anticipation that the feedback the industry has provided, coupled with the research we’ve produced and a closer look at complexity of colors and advancements in color systems will lead anyone who earnestly researches this topic to the same conclusion that we came to, just as MOTOR has,” Schulenburg said. “This is an important step, with more to come.”

Images

Featured image: A portion of the week-long blend study coordinated by the Society of Collision Repair Specialists (SCRS) is shown at the Global Finishing Solutions (GFS) Center for Excellence, at the GFS headquarters in Osseo, Wisconsin, in August 2022. (Credit: SCRS)

Blend study results slide provided by SCRS and CIC.

Solera screenshot provided by Solera and DEG.