California mulling bill to require that OEMs ensure lithium-ion battery recycling

By onLegal | Technology

A California bill that would require OEMs to ensure safe and responsible recycling of lithium-ion vehicle batteries has passed out of committee for a vote on the floor.

SB 615 would repeal existing state law that requires the Secretary for Environmental Protection to convene the Lithium-Ion Car Battery Recycling Advisory Group to review and advise the legislature on policies about the recovery and recycling of lithium-ion vehicle batteries sold in vehicles within the state.

Another requirement would also be repealed which calls for the advisory group to submit policy recommendations to the legislature to ensure lithium-ion vehicle batteries in the state are reused or recycled at end-of-life safely and cost-effectively as close to 100% of the time as possible.

SB 615 would instead require vehicle traction batteries to be recovered, and when possible, reused, repaired, repurposed, or remanufactured and recycled at the end of their useful life. Battery suppliers would be responsible for correct end-of-life management of a vehicle traction battery if it is removed from a vehicle still in service, or if the battery is offered or returned to its battery supplier.

Suppliers would be mandated to report information about the sale, transfer, or receipt of a vehicle traction battery or module.

If passed, the Department of Toxic Substances Control (DTSC) would have to conduct a study to determine if there is evidence of abandonment of orphaned batteries leading to environmental and health and safety hazards on or before Jan. 1, 2030, then every three years.

Also, under the bill, the DTSC may require qualified battery recyclers to report where the treatment of batteries takes place along with data on recycling efficiency for waste batteries, recovery of materials from waste batteries, and the yield of the final output fractions of lithium, cobalt, nickel, and copper.

In a written statement, Jessica Dunn, a Union of Concerned Scientists senior analyst specializing in lithium-ion battery sustainability, commended legislators for “recognizing the need to plan for the safe recycling of EV batteries.”

Doing so means key materials can be recovered and reused “thereby reducing the amount of mining for critical minerals like lithium needed to fully electrify our transportation system over the next several decades,” she wrote.

“Californians are buying more EVs than ever and we must start planning now for their retirements. A strong recycling policy means batteries will not end up in landfills but instead provide an excellent domestic source of minerals for the next generation of vehicles. Even with diminished capacity, the usefulness of batteries continues. They can be reused or repurposed and then eventually recycled so the materials recovered can be used to manufacture new batteries. But to accomplish that, we need public policy to ensure batteries don’t slip through the cracks.”

A July NPR article states that key steps in the battery recycling process mostly happen overseas, particularly in Asia.

“Companies there have spent years building up a battery supply chain in which recycling and building batteries are closely connected,” the article says. “But more and more batteries spend their lives powering electric vehicles in the United States. Shipping minerals halfway around the world costs money, creates carbon emissions, adds supply chain risks, and, from the U.S. perspective, pushes some jobs and profits overseas.”

The Department of Energy (DOE) says strong battery and critical material supply chains will allow for a seamless transition to clean energy technologies. It has awarded $1.82 billion to 14 projects that it says will build and expand commercial-scale facilities to extract lithium, graphite, and other battery materials, manufacture components, and demonstrate new approaches, including manufacturing components from recycled materials.

Combined federal and private sector investment totals more than $5.6 billion to boost American production of clean energy technology, according to the DOE.

Some OEMs have begun developing plans for their own battery recycling plants or already have them up and running.

OEMs are “all over the board” on storage from some having a process in place through their dealer networks to wanting them recycled, and some not providing any guidance, I-CAR Repairability Technical Support and OEM Technical Relations Manager Scott VanHulle previously said.

Reuters has reported that Nissan has begun leasing EVs in Japan to maintain control of its batteries. BMW hopes something can be done to keep batteries from being sold abroad; perhaps with the increase in the value of battery materials making recycling a more attractive option.

Rivian said during the 2021 SEMA Show that they want damaged high-voltage components and battery packs from total loss vehicles to be given back to them so they can be properly recycled. Lucid, at that time, said they planned to keep track of battery packs that are put back into its fleet.

Late last year, Toyota expanded its battery recycling network through a new collaboration with Cirba Solutions, a battery recycling materials and management company. The agreement optimizes its logistics network for end-of-life electrified vehicle battery collection, including those from hybrid (HEV), plug-in hybrid (PHEV), and battery electric vehicles (BEV).

Images

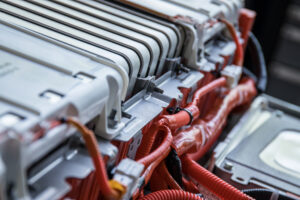

Stock close-up photo of a lithium-ion vehicle battery (Pasha Pechenkin/iStock)

More information

Biden’s plan to reduce emissions creates new environmental concerns for automakers