Shop owner: New collision estimating SkillsUSA event ‘went very well’

By onBusiness Practices | Education | Insurance | Repair Operations | Technology

A luxury-certified body shop owner and former Society of Collision Repair Specialists chairman said the inaugural SkillsUSA National Collision Damage Appraisal challenge “went very well” and drew interest from teachers accompanying the students.

Precision Body & Paint owner Ron Reichen, who served as both a judge and technical committee member for the new event, said committee members now plan on building a curriculum for vo-tech instructors seeking to teach the next generation of appraisers, adjusters and estimators.

Though its honorees are treated like any others, the appraisal competition will spend another two years as a demonstration event, according to Chris Evans (State Farm), chairman of the SkillsUSA Collision Appraisal and Total Loss Evaluation Committee. Demo events which “are doing well and have industry support” graduate to become official contests, SkillsUSA public relations manager Karen Kitzel explained in an email Monday.

Reichen said he was looking forward to developing the curriculum, and he planned to push the concept to the two vo-tech boards upon which he sits.

“We need them in the industry,” he said of estimators. As is the case for the refinishing competition, Reichen said sponsors and technical committee members would receive resumes of the contestants — a nice perk amid a skilled labor shortage. (Those interested in learning more or joining the panel can contact Evans at chris.evans.ca1b@statefarm.com.)

Reichen said the appraisal competition’s elements included examining three vehicles. The 13 entrants received an hour each to write assessments on an obvious total loss, a front-end hit, and a quarter panel replacement.

The total-loss portion of the event involved grading the vehicle like an insurance adjuster or a customer’s appraiser tasked with determining how much would be a fair settlement, Reichen said. Competitors looked at factors like tire wear, glass chips, stains and mileage in what is a “very sequential process” in the real world, according to Reichen, whose repair facility also offers vehicle inspection reports for totals.

Competitors examined and wrote up the two repairable vehicles using CCC, Reichen said. They had to enter in variables such as VIN Number, mileage, customer information, insured or claimant, date of loss, and production date, with penalties for omissions, he said.

“We made them harvest that,” he said.

Having CCC allowed for trim code lookups and for estimators to flag whether a part was one-time use.

Reichen said the students were also expected to populate the estimate with fields for pre- and post-repair scanning, set up and measure and accessing repair procedures.

Reichen said he had to put his foot down during the event prep when another judge from a large MSO argued, “‘we can’t charge for that'” about particular operations. The students’ sheets needed to be dictated by the requirements physical vehicle, not whether their hypothetical shop was charging for the work, Reichen argued. (For example, a need for corrosion protection had to be reflected on the estimate even if the shop did the work for free.)

Reichen prevailed. The MSO representative later during the event observed, “‘You know, I’ve learned a lot,'” according to Reichen, who said the experience might lead that judge to wonder of their chain, “‘Are we really leaving this much stuff on the table?'”

“‘I can’t even get my senior writers to write this good,'” the MSO judge observed at one point.

An earlier draft of the competition description involved “Make proper use of alternative parts available on the ‘Parts information document’ as applicable (e.g. New OEM, Aftermarket, Recycled, Rebuilt, reconditioned, etc.” However, Reichen said the competition instructed all the contestants to write using new OEM parts to avoid introducing parts choice subjectivity into the judging. Contestants also used the same labor rate and paint and materials multiplier to compete apples-to-apples.

Reichen said the competition wasn’t about the bottom line — it was about accurately capturing the damage on the vehicle. He also observed that he cared less about how many hours the appraiser wrote for damage — that skill could be trained — then the ability of the appraiser to spot damage.

The judges also granted extra credit for line notes and threw in a couple of trick questions, according to Reichen. For example, he said, competitors were expected to flag fog lights — but also know to write to aim them. A couple of the contestants caught it, he said, and one wrote to aim them but ironically missed the damage.

Reichen said all but one of the contestants missed one item — a new washer bottle to replace a cracked one.

High school contender Lynzi Binder of Carbon Career & Technical Institute (Jim Thorpe, Pa.) won the first gold ever for the event, which is technically still in the demo stage, and Green Bay, Wisc.-based Northeast Wisconsin Technical College’s Joel Taft took first at the college level.

Silver medals went to Jared Arfsten of Colorado Springs, Colo.-based Career Start (high school) and Michael Kunkle of Aims Community College-Windsor (college).

Reichen also noted that his mentee Eric Austin of Salem, Ore.-based Career Technical Education Center took the bronze in the high school competition, and Reichen was able to present the medal to the youth during the awards ceremony. Cayden Bailey of Utah Valley University took third place at the college level.

More information:

SkillsUSA Nationals 2018 winners

SkillsUSA contest descriptions

Images:

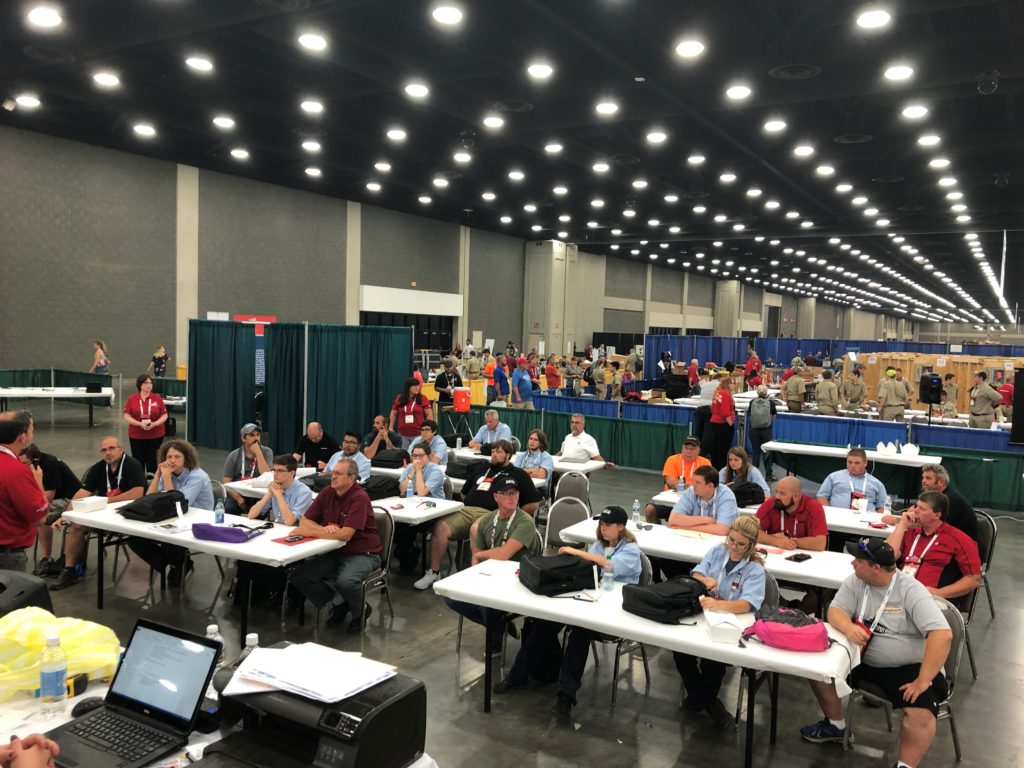

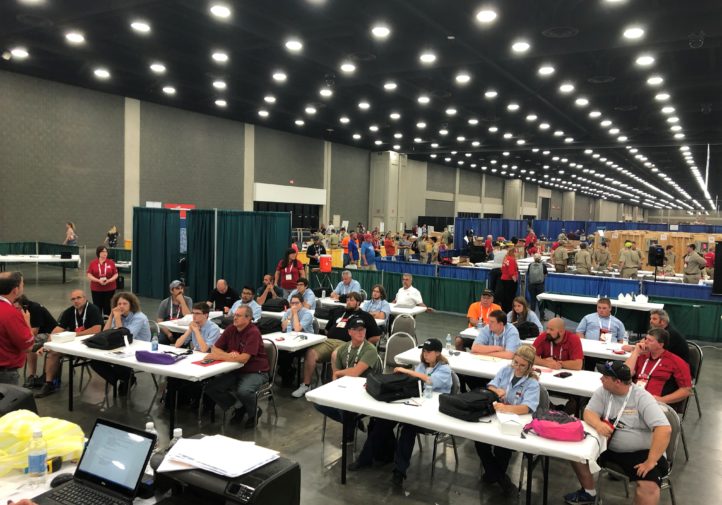

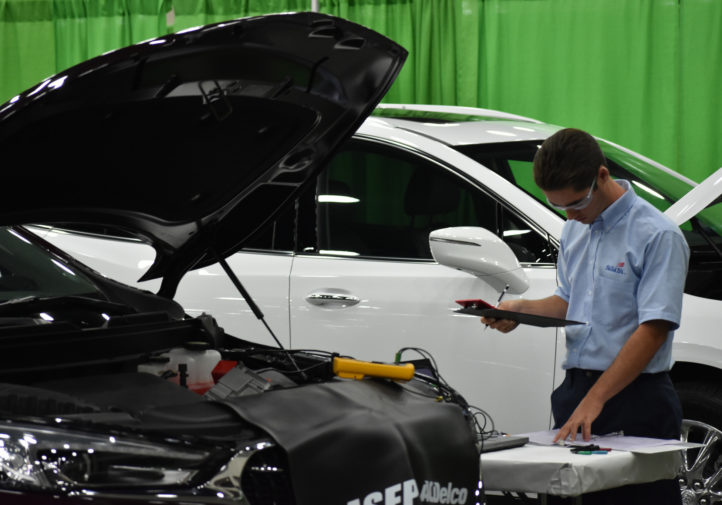

Gallery No. 4: SkillsUSA Collision Damage Appraisal contestants and the committee members behind the new demo program. (Provided by appraisal committee Chairman Chris Evans)

Gallery No. 7: Former Society of Collision Repair Specialists Chairman Ron Reichen (Precision Body and Paint) poses at SkillsUSA 2018. (Provided by SCRS)

Gallery No. 5: SkillsUSA Collision Damage Appraisal contestants and advisers are shown. (Provided by appraisal committee Chairman Chris Evans)

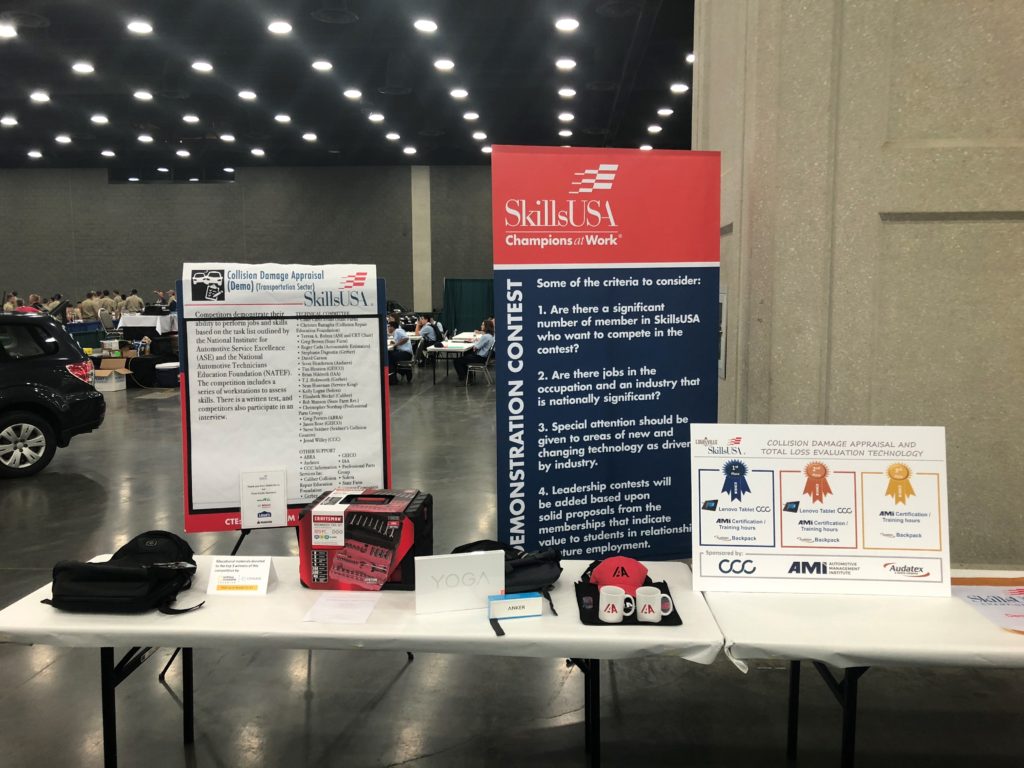

Gallery No. 20: A table touts the new demo SkillsUSA Collision Damage Appraisal category. (Provided by appraisal committee Chairman Chris Evans)

Gallery No. 6: SkillsUSA crowned the latest class of refinishing and collision repair rising stars last week — as well as up-and-comers in a new trial Collision Damage Appraisal category (pictured). (Provided by appraisal committee Chairman Chris Evans)

Gallery No. 1: SkillsUSA Automotive Refinishing Technology 2018 winners. (Janet Crowley, committee co-chairwoman)

Gallery No. 2: SkillsUSA Automotive Refinishing Technology 2018 competitors. (Janet Crowley, committee co-chairwoman)

Gallery Nos. 3, 8, 10-14, 16, 18-19, 21-42: The 2018 SkillsUSA Nationals event. (Craig Moore/SkillsUSA)

Gallery No. 9: The four gold medalists (two high school, two college) in the 2018 SkillsUSA collision repair and refinishing categories will also win $1,250 tool scholarships thanks to the Society of Collision Repair Specialists, March Taylor Memorial Fund and Snap-on. An SCRS sign congratulates contestants at the 2018 competition. (Provided by SCRS)

Gallery Nos. 15, 17: A scene from SkillsUSA 2018. (Provided by the Society of Collision Repair Specialists)