2018 Jeep Wrangler: Frame among significant high-strength steel content

By onMarket Trends | Repair Operations | Technology

The current-generation 2018 Jeep Wrangler’s body is more than 40 percent steels in high-strength or stronger grades, while the frame is nearly 80 percent high-strength or advanced-high-strength steels.

They’re among the elements that helped Jeep cut more than 112 pounds out of the popular vehicle compared to the outgoing Wrangler.

FCA in 2017 already confirmed the extensive use of aluminum on the Wrangler, but April Bagley of FCA body systems and components engineering provided a look at the vehicle’s steel last month during the 2019 Great Designs in Steel.

The Wrangler was the No. 16-selling vehicle in the country in 2018, according to Good Car Bad Car, so it behooves repairers to be ready for its structures.

Bagley noted that the OEM had to deal with an additional 32.85 pounds of functional weight, including materials to handle noise, vibration and harshness; keep passengers safe; and support the Wrangler’s 100-pound spare tire.

Jeep cut 54.45 pounds out of the body-in-white with material design and optimization, and achieved another 80.03 pounds of lightweighting with the closures, according to Bagley. Another 11.02 pounds fell through hardtop design optimization and using “low-density SMC in places,” Bagley said.

The OEM confirmed in 2017 that the off-road vehicle used aluminum in its doors. including the half-door option on the Rubicon; hood; windshield frame; and fenders. FCA’s free repair procedures indicate the tailgate outer is aluminum, while the inner is magnesium. (Note: You need to check the paid FCA procedures to do an actual repair. It’s also unclear if the free FCA PDFs are updated consistently to reflect the content on the paid site.)

Bagley said despite extensive aluminum and steel, the Wrangler didn’t actually have any aluminum-to-steel joints. She said Jeep used traditional aluminum-aluminum joining methods, such as structural adhesive and rivets, and noted the door employed six joining methodologies, ranging from crimping and hemming to spot welding.

Technically, the hood might not always be aluminum. FCA used the nonferrous metal for the high-volume Rubicon, Sport and Sahara variants, Bagley said. But she said the OEM used steel hoods for energy management purposes in global markets with pedestrian protection requirements, and noted she expected it’d appear on a buzz model at some point. (As of now, the U.S. doesn’t have pedestrian protection requirements.)

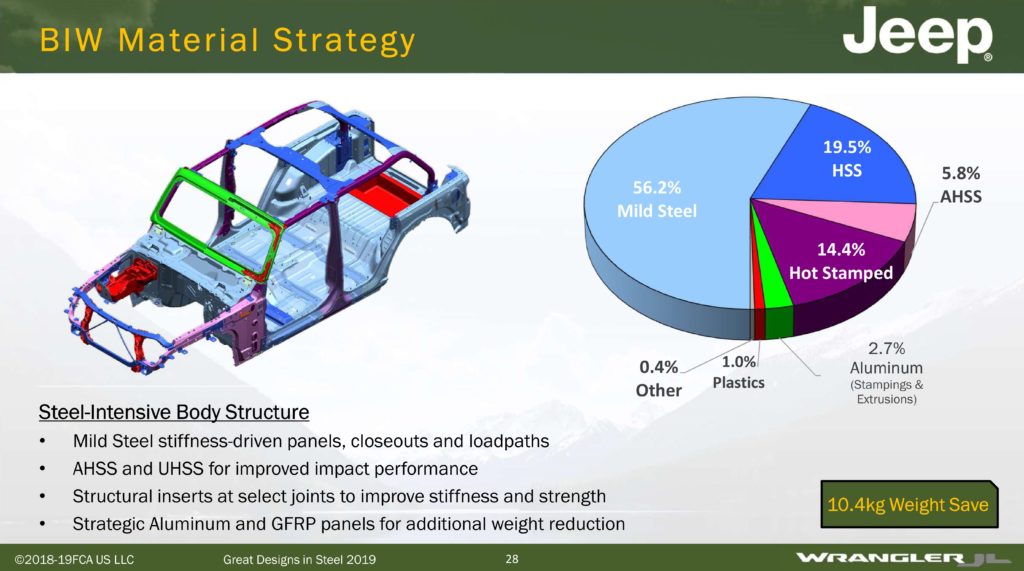

A diagram from Bagley’s presentation indicated 56.2 percent of the body-in-white is mild steel and 19.5 percent is high-strength steel.

She said the body’s 5.8 percent advanced high-strength steel included load beams and the A-pillar for small-overlap crash tests, and its 14.4 percent hot-stamped ultra-high-strength steel included the “upper cage structure.”

Looking beyond steel, 2.7 percent of the body is aluminum — the closures weren’t counted here, only the aluminum windshield frame — and the 1 percent which is plastic includes stiffening reinforcements and the cargo top, according to Bagley and her presentation. A final 0.4 percent is “Other,” according to the presentation.

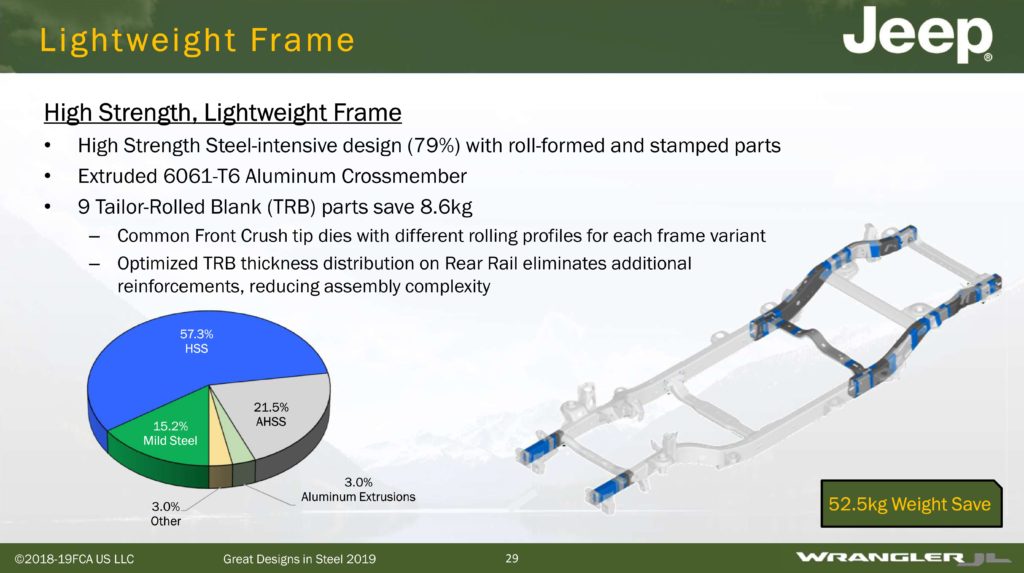

The frame is only 15.2 percent mild steel.

“It’s a high-strength-steel-intensive frame” with roll-formed and stamped parts, Bagley said. 57.3 percent is high-strength steel, and 21.5 percent is advanced high-strength steel. The 3 percent aluminum includes a 6061-T6 crossmember, according to Jeep’s presentation. A final 3 percent is “Other,” according to the presentation.

According to the presentation, nine tailor-rolled blanks cut 18.96 pounds.

“This helps us with eliminating reinforcements and managing our assembly of the frame efficiently,” Bagley said.

Her presentation tied those two achievements to Jeep optimizing the tailor-rolled blank thickness on the back of the Jeep frame. The slide also associated “Common Front Crush tip dies with different rolling profiles for each frame variant” with tailor-rolled blanks.

Body variants include four-door and two-door Wranglers, with multiple unique styles depending on the particular subconfiguration, according to the presentation.

However, Bagley noted that 80 percent of the parts carry over to the two-door variant, with a similiar proportion transferring to the truck variant.

More information:

Free FCA Mopar Repair Connection site

Paid FCA Mopar Tech Authority OEM repair procedures site

2018 Jeep Wrangler presentation

FCA, May 15, 2019

Images:

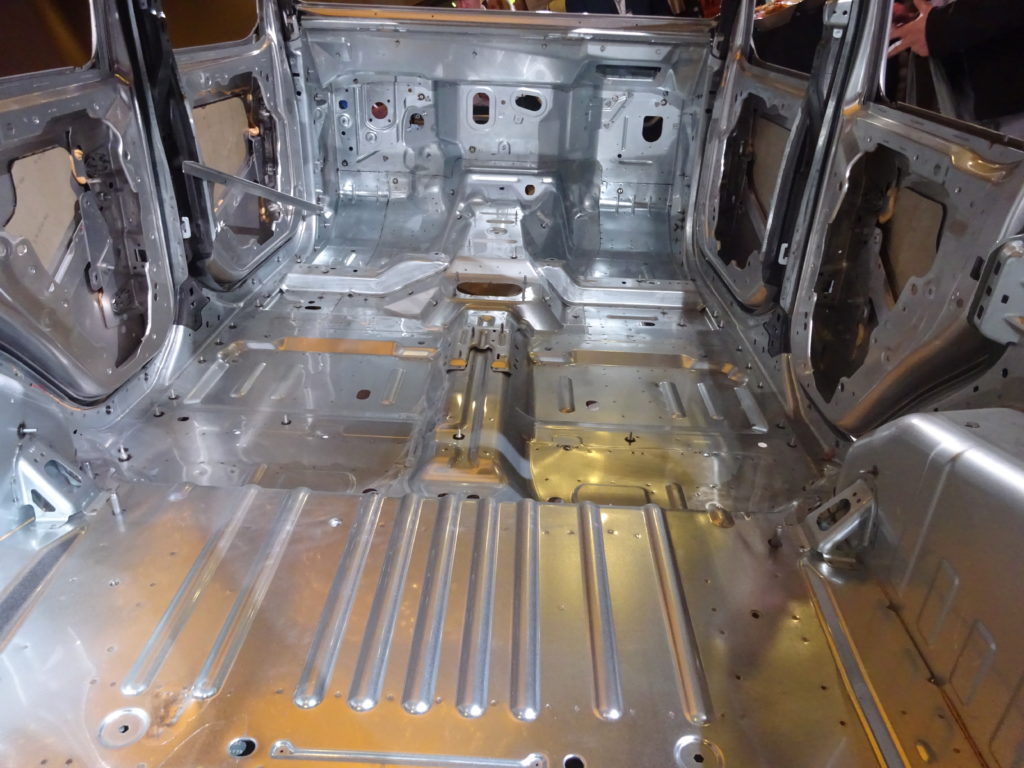

The doors on the 2018 Jeep Wrangler are aluminum, but most of the body-in-white is steel. The tailgate outer is aluminum, while the inner is magnesium. (John Huetter/Repairer Driven News)

The doors on the 2018 Jeep Wrangler are aluminum, but most of the body-in-white is steel. (John Huetter/Repairer Driven News)

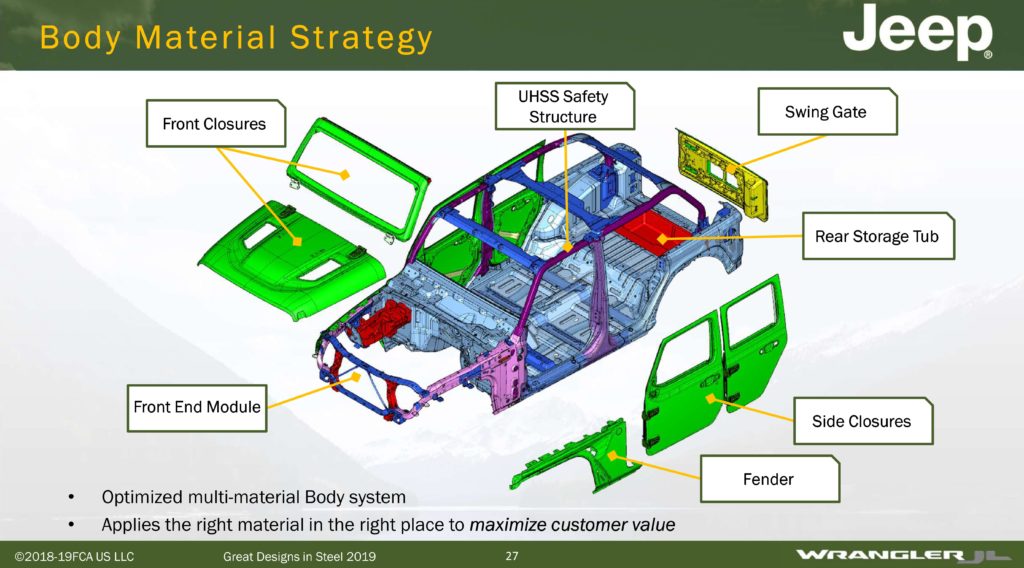

Materials on the body of the 2018 Jeep Wrangler are shown. Green parts are aluminum, yellow is magnesium, and red is plastic. (Provided by Jeep via Great Designs in Steel)

Materials proportions on the body of the 2018 Jeep Wrangler are shown. (Provided by Jeep via Great Designs in Steel)

The frame of the 2018 Jeep Wrangler is only 15.2 percent mild steel. (Provided by Jeep via Great Designs in Steel)