New Ford ‘On Target’ highlights metallurgy of 2020 Lincoln Corsair

By onEducation | Market Trends | Repair Operations | Technology

Ford’s latest “On Target” collision repair newsletter describes a 2020 Lincoln Corsair which mostly relies on steel but incorporates some aluminum.

If you haven’t read one of Ford’s “On Target” newsletters before, check them out. They’re a free quarterly resource for the collision repair industry and anyone else who’s interested. The content is often technical — notably the articles which break down a specific repair procedure — but not to the point of inaccessibility. None of it is meant to be a substitute for consulting the actual OEM repair procedures, but it’s a nice foundation for what you might find in those manuals or on the vehicle.

Lincoln revealed the Corsair in April 2019 but offered little detail about its body construction since other than to note its “exquisite contouring” on the sides and the incorporation of a composite dual-wall dashboard.

“To help ensure a whisper-quiet ride, a dual-wall dashboard in the engine compartment provides an additional sound-dampening barrier between passengers and the engine,” Lincoln wrote in 2019. “Made with sheet-molded composite material with an air gap in between, the walls of this feature significantly reduce the traveling sound from a running engine.”

The new On Target explained what materials surround that dual-wall dash. (It also noted another piece of noise, vibration and harshness control: mastic pads on the floor pans to dull sound.)

The OEM said the bodyside outer panels are mild steel, as is the liftgate.

We’ve had it confirmed separately that the Corsair’s hood is aluminum and the fenders and doors are various grades of steel. The fenders, doors and hood are “(b)olted, removable,” with steel hinges on the hood, according to the newsletter.

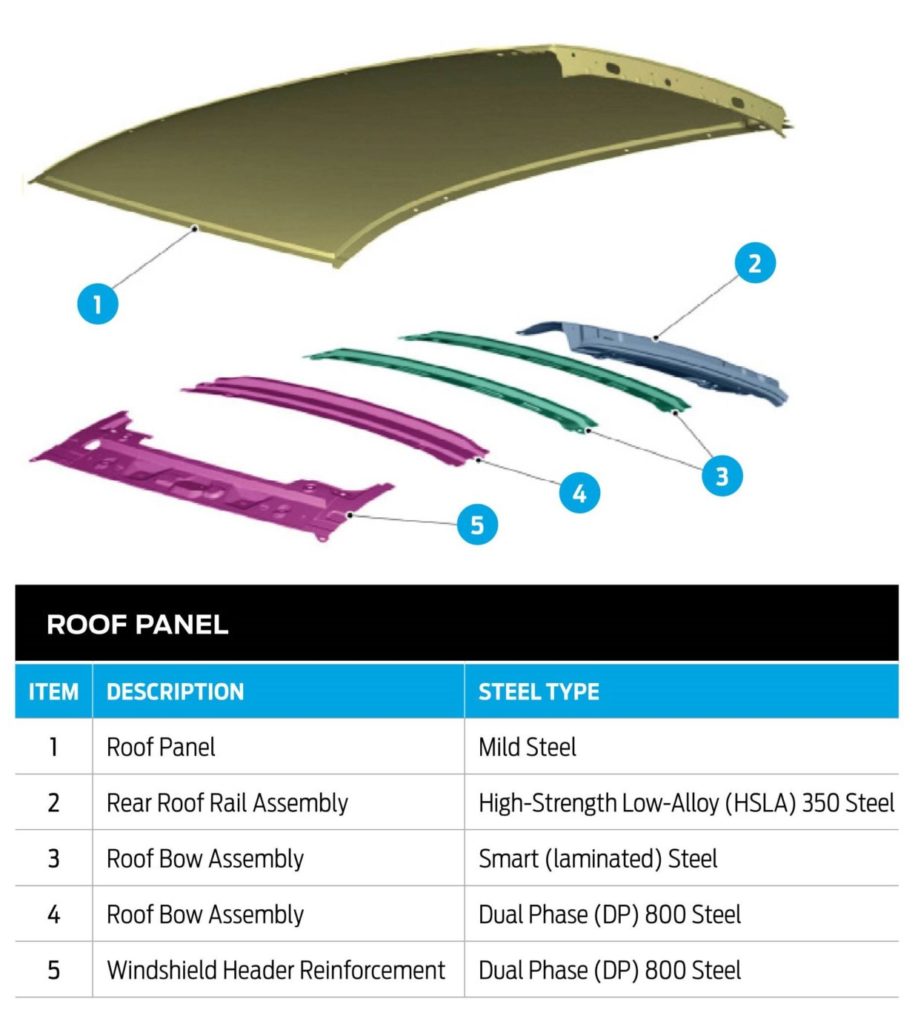

Ford also drew special attention to the Corsair’s roof and roof bows in the On Target. The full roof panel is mild steel. (It’s not clear what material Ford used for its panoramic roof structure.) The rear roof rail assembly is high-strength low-alloy 350 steel, while the windshield header reinforcement and front roof bow assembly are dual-phase 800 steel. The latter’s tensile strength can place it in the ultra-high-strength steel category. Two roof bows are “Smart Steel,” an interesting new laminated steel product that can be spot-welded in the factory.

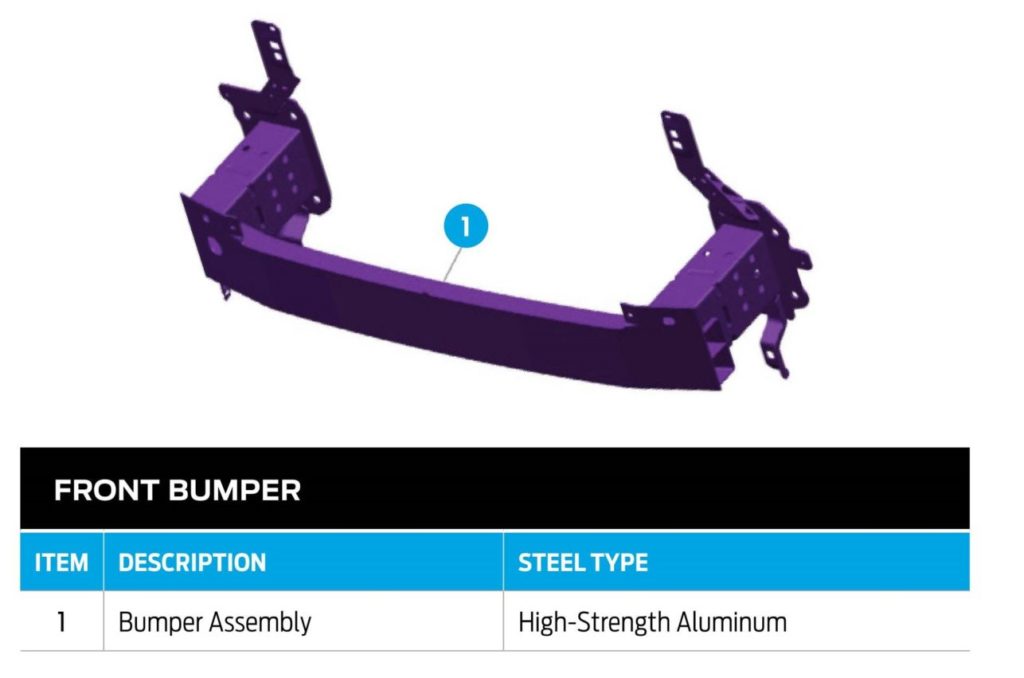

The front bumper beam is “high-strength aluminum,” while the rear beam is “Boron ultra-high-strength steel,” the On Target states.

“Bumper beams are typically constructed of high-strength or stronger class steel,” the On Target warns. “If the bumper beam shows evidence of a kink or tear, it is not repairable and must be replaced. The use of heat to repair these components is not allowed, as it will weaken the component. Minor damage may be corrected through the cold-straightening method only.

“For more information, refer to Section 501-26: Body Repairs – Vehicle Specific Information and Tolerance Checks, Description and Operation.” (Emphasis Ford’s.)

The front frame rails are dual-phase 600 high-strength steel, which can be rated with enough megapascals to reach the advanced high-strength steel level. Ford said it built the “(f)ender reinforcement tube” out of dual-phase 800 steel and used boron ultra-high-strength steel for the rear frame rails.

“Body structure constructed of Boron, Dual Phase (DP) and high-strength steels,” Ford wrote.

Lincoln sold 25,815 Corsairs/MKCs in 2019, making the vehicle the company’s No. 2 seller behind the Nautilus/MKX.

More information:

“2020 LINCOLN CORSAIR: VEHICLE-SPECIFIC BODY CONSTRUCTION”

Ford On Target, March 2020

Images:

The 2020 Lincoln Corsair is shown. (Provided by Ford)

The 2020 Corsair nonpanoramic roof construction is shown. (Provided by Ford)

The 2020 Corsair aluminum front bumper beam is shown. (Provided by Ford)