Texas A&M announce technique to 3D-print martensitic steels without flaws

By onAnnouncements | Market Trends | Technology

Texas A&M announced this month it and the Air Force Research Laboratory had figured out how to 3D-print martensitic steel “into very sturdy, defect-free objects of nearly any shape.”

Martensitic steel has a range of 900 MPa to 1,700 MPa, SSAB said in 2017. It can be work-hardened at the factory to achieve strengths equivalent to boron steel, and can be shaped into such structures as sill reinforcements, seat internal or base structures, 1,400 MPa cold-formed door intrusion beams, roll-formed protection for electric vehicle batteries — and bumper reinforcement beams.

And that’s two years prior to the Texas A&M-Air Force 3D-printing strategy, which could lead to the light, strong steels being used for more complex shapes. The ability to 3D-print such parts also raises the intriguing possibility of printing replacement components on-demand or adjusting a structural component on the fly — perhaps to improve crash-test performance — without having to retool.

“Strong and tough steels have tremendous applications but the strongest ones are usually expensive — the one exception being martensitic steels that are relatively inexpensive, costing less than a dollar per pound,” Texas A&M Materials Science and Engineering Department head Ibrahim Karaman said, according to Texas A&M. .“We have developed a framework so that 3D printing of these hard steels is possible into any desired geometry and the final object will be virtually defect-free.”

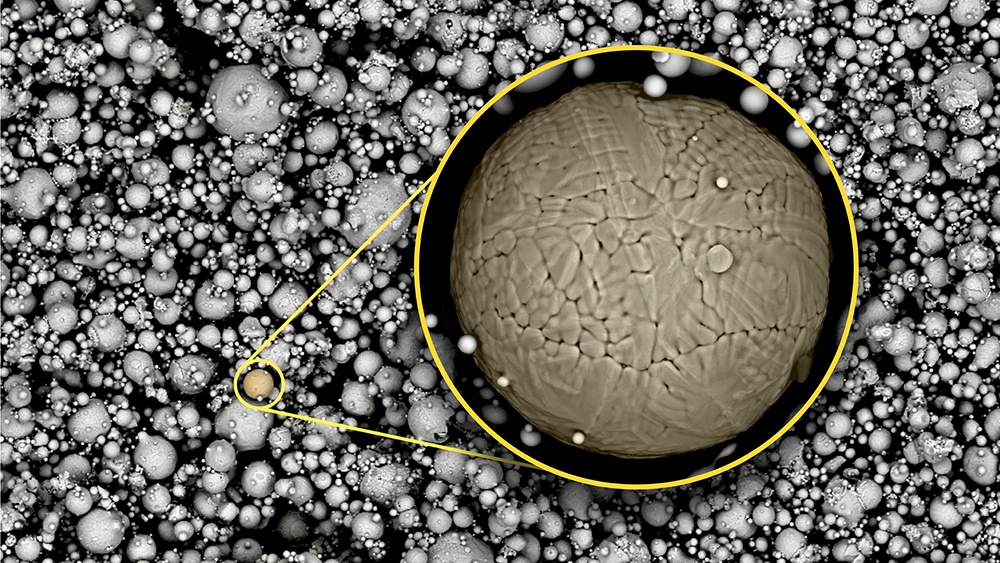

According to Texas A&M, 3D-printing martensitic steels historically left the metal with unwanted pores.

“Porosities are tiny holes that can sharply reduce the strength of the final 3D-printed object, even if the raw material used for the 3D printing is very strong,” Karaman said in a statement. “To find practical applications for the new martensitic steel, we needed to go back to the drawing board and investigate which laser settings could prevent these defects.”

Texas A&M and the Air Force Research Lab figured out how to predict which settings yielded better martensitic steel.

“Testing the entire range of laser setting possibilities to evaluate which ones may lead to defects is extremely time-consuming, and at times, even impractical,” study primary author and Texas A&M grad student Raiyan Seede said, according to the university. “By combining experiments and modeling, we were able to develop a simple, quick, step-by-step procedure that can be used to determine which setting would work best for 3D printing of martensitic steels.”

Texas A&M used a welding mathematical model to predict what would happen to martensitic steel powder and tweaked it using real-world data.

“After a few such iterations, their framework could correctly forecast, without needing additional experiments, if a new, untested set of laser settings would lead to defects in the martensitic steel,” the college wrote. “The researchers said this procedure is more time-efficient.”

According to Seede, the same process will work for other metals.

“Although we started with a focus on 3D printing of martensitic steels, we have since created a more universal printing pipeline,” Karaman said, according to Texas A&M. “Also, our guidelines simplify the art of 3D printing metals so that the final product is without porosities, which is an important development for all type of metal additive manufacturing industries that make parts as simple as screws to more complex ones like landing gears, gearboxes or turbines.”

The study first appeared in the December 2019 Acta Materialia.

More information:

Acta Materialia, December 2019

“Texas A&M Researchers Develop Method For 3D Printing Hard Steels Flawlessly”

Texas A&M College of Engineering, April 16, 2020

Featured images: Martensitic steel powder for 3D printing. (Raiyan Seede/Texas A&M Engineering Microstructural Engineering of Structural and Active Materials Group)