Expert: Body shops should make vehicle No. 1 priority, educate and involve the customer

By onAssociations | Business Practices | Education | Repair Operations

Collision repairers should treat the vehicle as paramount, even ahead of the customer or one’s shop, a reinspector and expert witness advised in a Society of Collision Repair Specialists virtual course released this fall.

Auto Damage Experts operations president Smith presented “Order of Importance: Car, Client and then the Shop…and Why.” during the virtual Repairer Driven Education released in November 2020. The course and more than a dozen other video RDE classes will be available for replay through Aug. 31 on rde.scrs.com.

No. 1. Car. Putting the car first is “controversial,” Smith said. But a body shop can tell what a vehicle needs by using OEM repair procedures and applying its expertise.

“We are the experts,” he said. The customer lacks the information on how to fix the vehicle properly, as do most insurers, he said.

That’s why the customer is No. 2, Smith argued. The consumer is an important factor, but they’re not educated on the correct repair, he said. (Nor do they understand alternative parts terminology used by the industry, he said.)

Like a patient going to a doctor, they’re reliant on the shop’s expertise.

Repairers also need to turn away work sometimes to do the right thing for the car or consumer, Smith said.

“Not every repair is a good repair,” Smith said. Some shops want to handle every repair, but sometimes that decision isn’t the right call, he said. If your facility lacks the specialized tools and training to fix that vehicle, then your customer should take it elsewhere, according to Smith.

“There’ll be another repair for you,” Smith said. Fixing a vehicle without the proper capability increases risk and liability, and “you’re not treating the customer right,” he said.

Smith at one point shared a lesson from his own career that demonstrated the importance of OEM procedure compliance. His shop conducted a “pretty significant repair” to the left rear of a 2004 Lexus LS. The work looked “great,” but Smith later found out that Toyota’s OEM procedures called for a different repair.

He had to call the owner and report, “‘We’re gonna have to buy a $55,000 Lexus because I didn’t follow a procedure that I didn’t know about.'”

The shop conducted the repair the way “every Lexus dealer” on the West Coast fixed such damage,” according to Smith. “I called ’em and asked ’em,” he said. “That didn’t help me. That wasn’t gonna protect me. I was still liable for that repair.”

Smith at another point said shops should let OEM procedures, not their experience, tell them what ought to be done on a vehicle. Then draw upon experience to execute those OEM instructions, he said.

2. Customer. Though the customer isn’t the repair expert, the shop should still involve them in the repair, according to Smith.

No. 1 on a customer “bill of rights” would be the “right to safety,” he said. This would be a vehicle repaired using OEM procedures, he said. No. 2 would be the customer’s “right to be informed,” according to Smith.

“It is their property,” Smith said.

The customer should also have the “right to choose,” Smith said. If an insurance estimate includes a part a repairer doesn’t think would be correct, the customer should be given the opportunity to make that determination, he said.

Shops should bring customers into the decision-making process, he said. Customers must live with the shop’s choices and deserve to have an impact on those choices, he said.

A body shop isn’t protecting a customer by failing to involve them, Smith said. Shops will seek to spare the customer from inconvenience or having to get involved in the process, but “several problems” exist with that philosophy, according to Smith.

You’ve taken the customer’s voice away, he said. The shop also has acted without permission, which raises liability concerns, he said.

What happens when the customer visits another shop “and you’re not here” to help them, Smith asked. He recalled a situation where an insurer’s local office began to write for alternative parts after 20 years of never doing so.

For a longtime policyholder, “that wasn’t what they bought” in terms of insurance coverage, Smith said. If the shop didn’t inform the customer of this change, “who will?” And who would educate them on the difference between the parts?

He said shops had the same responsibility to inform a customer as a doctor did with a patient.

Smith said that demonstrating that your shop worked for the customer was “probably the most impactful” thing the business could do for itself.

Communication has been the collision repair industry’s “No. 1” issue for the past 30 years. He observed that while more communication methods existed today than ever, “we’re still not communicating with the clients.”

Smith said the shop should send a customer a copy of the estimate — don’t just tell them the amount. When the facility prepares a supplement, send it to the insurer and customer at the same time, he said.

Give the customer the documentation you’re relying upon in your decisions, Smith said. This will make your facility more “reliable” and “trustworthy.” It also allows the customer to get involved and advocate to the insurer alongside you for a particular part or procedure.

“That way they have a right to protect themselves,” he said.

Make sure a customer understands what an insurer is refusing to reimburse and which elements of the carrier’s repair would violate OEM procedures, Smith said. Customers will start asking “hard questions,” he said.

If you empower and inform a customer, “your client will truly appreciate it,” Smith said. They’ll remember your facility after the next accident because “nobody else is doing it,” he said.

3. Shop. Doing what was best for one’s shop ranked No. 3 behind one’s duty to the vehicle and to the customer, according to Smith. After you’ve squared away the car and customer, focus on the best move for your shop.

Protect your shop’s reputation and avoid liability, he said. Keep your business financially healthy so it’s around for your employees and to honor your warranty obligations to customer, he said.

Smith also encouraged empowering everyone at the shop from the estimator to the detailer to make the best decision. With the car-customer-shop philosophy, it’s easy and the decisions are more consistent, Smith said.

He offered the example of a technician who concludes that he could repair damage but not fully restore it to the prior condition. The answer is a no-brainer with the car-customer-shop thought process: The part must be replaced.

Repairing typically has higher gross profit than replacing a part, but “that’s not how we should make choices,” he said. Techs can make better time on repairs often as well, but that’s not the right mindset either, according to Smith. Shops must choose what’s best for the car, followed by what’s best the customer. Then you can worry about factors like technicians, insurers and gross profit only after the first two are satisfied.

“Remember, you have the liability,” Smith said — not the insurance adjuster. He said the concept had once been explained to him as as every car being a “‘potential time bomb.'”

By prioritizing the car and customer first, self-serving decisions are eliminated, according to Smith.

Employees should be prepared to make decisions with the boss absent, according to Smith. Smith recalled once being on vacation and taking multiple calls from his company. His father pointed out, “‘You’re a horrible manager.'”

Consistency in serving customers is also desirable for a facility, and keeping staff on the car-customer-shop order of priority can permit repeatable experiences, Smith said.

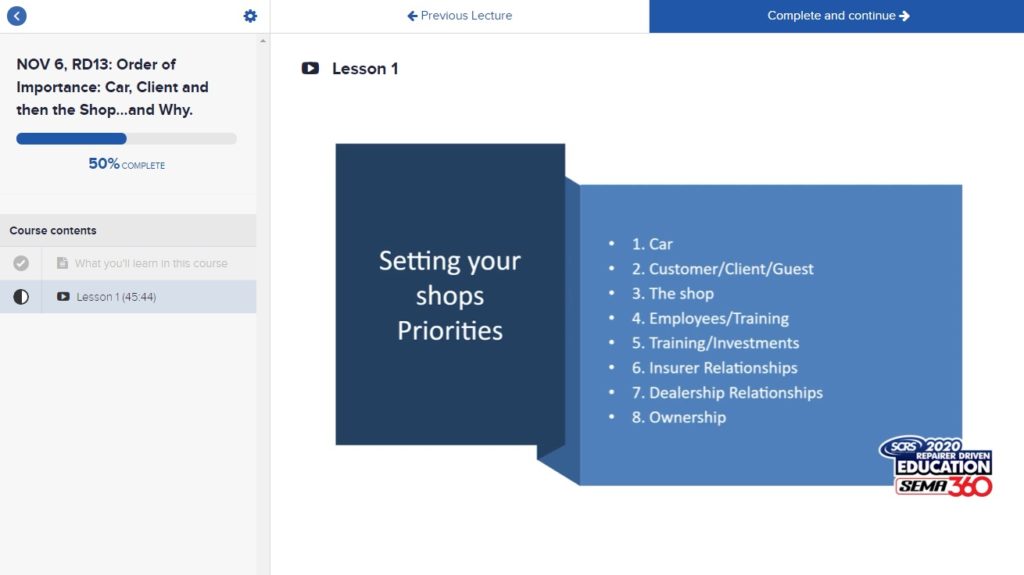

Smith offered examples of five secondary interests a shop might prioritize after addressing their responsibility to the car, customer and shop. He said shops might have a different ranking for No. 4 and onward, and that was fine. (But car, customer, shop are always No. 1-3, in that order.)

4. Employees/training. Smith said you want techs to have the correct tools and the best information. He also pointed out how not screwing up the car could free up money for training. At one point in the webinar, he recounted a Volkswagen-certified shop who had to buy back an Touareg for $40,000 after violating VW’s ban on pinchweld clamping. That’s $40,000 which could have been spent on training instead of “thrown away,” he said.

5. Training/Investments.

6. Insurer Relationships. Consistency in one’s process will give you a better relationships with insurers because they can rely upon it — “even if they don’t like paying you for everything,” Smith said.

They also must make a choice on whether they’ll argue with your or the customer. “Don’t take the pressure off the carrier,” he said.

7. Dealership Relationships. Consistency in repair quality matters here, Smith said. A shop is not helping a dealership by putting out a bad product, he said.

8. Ownership.

More information:

“Order of Importance: Car, Client and then the Shop…and Why.” (Replayable through Aug. 31, 2021)

Society of Collision Repair Specialists, 2020

SCRS Repairer Driven Education virtual courses (Replayable through Aug. 31, 2021)

I-CAR OEM repair procedures portal

Images:

Auto Damage Experts operations president David Smith speaks during a 2020 virtual Society of Collision Repair Specialists Repairer Driven Education series course. (Screenshot from SCRS video)

Auto Damage Experts operations president David Smith said the car, customer and body shop should always rank Nos. 1-3 in a shop’s mind — in that order of importance. Other priorities can be added after that in whatever order best suits the shop, Smith said during a 2020 virtual Society of Collision Repair Specialists Repairer Driven Education 2020 course. (Auto Damage Experts slide via SCRS)