Responding to ‘extreme demand,’ Wake Tech adds degree program in collision repair, opens $42M facility

By onCollision Repair | Education

Wake Technical Community College has opened a $42 million automotive facility and added a degree program in collision repair, responding to an unmet demand for technicians, according to educators at the North Carolina school.

“I could place every single student that I have,” Clark Correll, program chair for Collision Repair and Refinishing, told Repairer Driven News. “There’s just extreme demand for them, in every facet – dealerships, independents, everywhere. I could place every single one. I get calls constantly.”

As of January, Wake Tech has been offering a two-year Associate in Applied Science degree in Collision Repair and Refinishing Technology, in addition to its diploma and certificate programs.

For the time being, the program is limited to 10 students, as the program gears up its equipment and facilities, Dave Favre, Wake Tech’s dean of transportation, told RDN. The program will grow by another 16 students in June, toward an eventual maximum enrollment of 80.

The new degree program is designed to “provide the knowledge and skills to complete structural and non-structural damage repairs and paint and refinish on automotive equipment,” the college says. Graduates should qualify for entry-level employment, with advancement depending on the training completed, knowledge and ability levels, work performance, and ethics.

Students take classes in structural and non-structural repairs, paint and adhesives, paint, special finishes, automotive estimating, and welding. They’re also required to take five general education classes, broadening their knowledge.

“That includes some of the soft skills, English, math, communications, and such to obtain a degree,” Favre said. It also includes classes that can be applied to a general automotive degree, if a student wants to change their path.

Instruction takes place in the 15,000-square-foot collision repair center in the new Hendrick Center for Automotive Excellence, which boasts Two Car-O-Liner frame machines, four Blowtherm paint booths, an Axalta paint mixing system, and a welding lab equipped with eight Car-O-Liner welders, where students learn to weld steel, stainless steel, and aluminum.

“We have the best facility that I’ve ever seen, and I’ve been in a lot,” Correll said. “It’s state of the art. Plenty of room to move. Fantastic equipment. Just best of the best.”

The new facility was made possible by a number of Wake Tech’s industry partners, particularly Hendrick Automotive Group, for which the center is named. Hendrick established a $1 million endowment to support students, faculty, staff, and technology in the college’s automotive programs.

Industry partners that provided support include Advance Auto Parts, which donated $250,000 to increase the number of women and other underrepresented groups in automotive training programs through its Future Technicians Program scholarships, and Axalta Coating Systems, which donated $250,000 for student scholarships and faculty support, and another $65,000 for equipment and supplies.

“We’re thrilled to open what is without a doubt one of the premier automotive training facilities in the country,” said Wake Tech president Scott Ralls at the center’s May 13 ribbon cutting. “Automotive maintenance and collision repair have changed so drastically, and technicians today need highly specialized skills. Now, we’ll be able to provide the [region’s] many dealerships and service centers with the qualified workforce they need.”

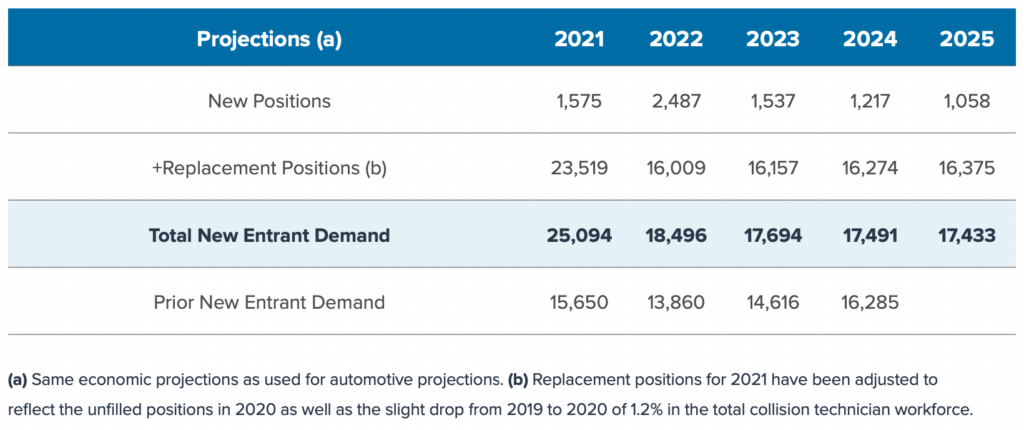

As the TechForce Foundation has documented, the industry is seeing a nationwide automotive technician shortage. In its 2021 Technician Supply & Demand report, the foundation quotes federal Bureau of Labor Statistics projections that 88,000 collision repair positions will become vacant by 2025, mainly through retirement.

At Wake Tech, Correll and Favre said there’s plenty of interest in the program from students, who recognize the opportunities that a career in the collision repair industry present.

Correll said there’s a growing recognition that collision repair “is very technical. Just the repair procedures have changed so much in the past 20 years that you have got to stay on top of your game all the time. Even after you get into the field, your education never stops. You’re constantly going to training, learning new procedures and such.”

“We’ve actually got the ADAS [advanced driver assistance systems] equipment to incorporate into our training also,” he added. “And we’re moving towards electric vehicle and hybrid technology, just sprinkling into it collision repair.”

Most of the students envision beginning their career by getting a job at a body shop, Favre said, while a smaller percentage have plans to open their own business. “I have one student right now that wants to export cars, so he wants to work for himself,” he said.

Several Wake Tech students recently put their educations on display at the SkillsUSA state competitions. Benjamin Pajerski placed first in Welding Technology and will compete at the SkillsUSA national competitions in June. James Keen finished fifth in Collision Damage Appraisal and Jeanluc Cook took third in Collision Repair Technology.

The Hendrick Center for Automotive Excellence is the first of five major expansion projects funded by Wake County’s 2018 bond, which passed with 65% of the vote. The architect for the project was Gensler, and the construction manager was Brasfield and Gorrie. Wake Tech’s project manager was Daniel Edwards.

More information

College opens Hendrick Center for Automotive Excellence

https://www.waketech.edu/post/wt-news-story/11721

Students excel at SkillsUSA state competition

https://www.waketech.edu/post/wt-news-story/11833

Several automotive scholarships offered amid worsening nationwide tech shortage

Images

Featured image: A Wake Tech student competes in the SkillsUSA state competitions on May 3.