I-CAR demonstrates EV battery, enclosure testing methods

By onCollision Repair | Education

In its latest “Repairers Realm” web series episode, I-CAR along with Redline Detection’s Chuck Kinkade, demonstrated two electric vehicle battery enclosure tests that are required by Ford post-collision.

The first step, regardless of OEM, is to do a pre-scan to look at temperature and battery voltages, said I-CAR ADAS/EV Lab Research & Specialty Training Senior Manager Niel Speetjens.

“We want to see those cells at a very equal level; preferably no difference than 150 millivolts per cell,” he said. “That is a must once a vehicle comes in after a collision. The reason being is that if the car gets into an accident, a lot of G-forces are implemented on the high-voltage battery. …we could have a concussion inside one of our cells or multiple cells.”

G-forces could cause micro-cracks in the battery, he added.

Next, check your gloves to make sure that they’re good, power down the battery, and make sure it has zero potential then plug in the high voltage disconnect.

“You’re connecting the same way you would connect the actual power connectors,” Kinkade said. “These are air-only tests for Ford. That’s part of the OEM service procedures. That’s something that you definitely want to do is make sure that you follow the OEM service procedures. …This is a flow test. I think what we see probably most often is a pressure decay test. I would say the second most often would be a vacuum rise test.”

To conduct the air flow test, a dual machine was used that includes evaporative emissions and air testing, which can be found in Ford’s Rotunda Program. Prior to testing Ford requires the vent patch to be sealed off with tape.

Repairers will monitor the flow meter until the ball goes to the bottom of the gauge. Reaching the bottom of the gauge means that there isn’t a leak. If it floats or doesn’t drop, a leak is present in the battery, Kinkade said.

The amount of time the test takes depends on the type of test, the testing equipment, the size of the battery enclosure and the battery, how much internal volume, and battery stabilization time.

A viewer asked if the battery has to be removed before testing. I-CAR ADAS and EV Instructor Joel Dufkis said that depends on the manufacturer.

“For the Ford Mach-E, in order to do this test, you have to cover that vent patch which is up underneath the rear seat area. So you have to drop the battery to do this test,” he said.

Kinkade added that at least one OEM, which he didn’t name, is developing a test for that can be conducted with the battery in the vehicle and a separate test if it’s out of the vehicle.

“The difference is that when it’s out of the vehicle and you do the pressure and closure test, you tape the umbrella valves or safety valves closed so we can have a little higher pressure,” he said. “You get a little better resolution on your test.”

To find out if EV battery enclosures contain water after they’ve been in floodwater Kinkade said, depending on the OEM, both pressure and vacuum tests are available. The vacuum test operates more like real-world conditions because the repairer would be looking for whether or not vapor is getting inside the battery.

The third test demonstrated was for battery coolant leaks. A regular pump tester like those used on internal combustion engine (ICE) vehicles was used to test pressure and the cooling system. When conducting the test, repairers need to look for pressure to drop after a few minutes and once the test is complete, stabilize the battery.

I-CAR Technical Programs & Services Director Dirk Fuchs said every OEM has different requirements for when the test should be done. To find out, repairers would need to check OEM repair procedures and position statements, he said.

A nano gas test can also be used in place of a soapy water test to check for enclosure leaks. Kinkade said to start out at the highest detection sensitivity for a quick check all the way around the battery. If a leak is found, turn the sensitivity down on the detector to pinpoint the location of the leak. In many cases, he said, the test can tell repairers which direction the leak is coming out of the battery.

It’s best to start the test around the major areas, especially in areas where repairs have already been done. Around the connections and lid should also be checked, especially on batteries that have replaceable seals.

Kinkade pointed out that any equipment that logs data gives repairers access to reports that can be saved, linked to VINs, and be included in post-scan reports.

It’s possible to only have to replace a damaged enclosure if the battery proves to be undamaged, Dufkis said. “For Ford, if the battery case is within X amount of damage repairers can swap everything from the old battery to the new housing, which saves a significant amount of money but depends o the manufacturer so check the procedures.”

Speetjens said it’s important to always remember that conducting the tests involve working under live conditions so getting the right information and the right education before you go inside a battery to repair a casing, a seal, or fix battery cells is incredibly important to maintain repairer safety.

A viewer asked if an infrared heat gauge can be used to do a pre-check of the battery while it’s still installed before working on the vehicle. Fuchs said it’s best to use a thermal image camera instead to see if fluoride gasses are present. If they are, a thermal event and fire could occur.

To check for OEM repair procedures and position statements, repairers can visit oem1stop.com. Information from Ford can also be found at motorcraftservice.com.

For those looking to learn more about EV safety and repairs, I-CAR provides a five-day hands-on course at its Chicago Technical Center.

Images

Featured image: A leak test is performed on an electric vehicle. (Credit: I-CAR “Repairers Realm” screenshot)

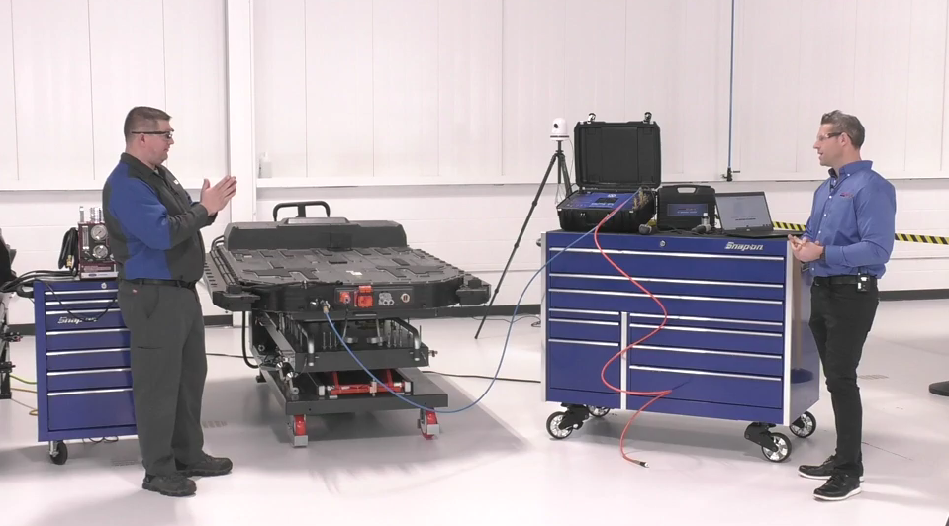

I-CAR ADAS and EV Instructor Joel Dufkis and Redline Detection’s Chuck Kinkade discuss EV battery and enclosure testing on Jan. 25, 2023. (Credit: I-CAR “Repairers Realm” screenshot)