CIC Estimating Committee overviews recent changes to CCC, Mitchell and Qapter

By onAnnouncements | Collision Repair | Repair Operations

Procedure pages (P-pages) are constantly changing and it’s important for the collision industry to be up-to-date on the newest versions, Danny Gredinberg, Database Enhancement Gateway (DEG) administrator, said during a presentation at a Collision Industry Conference meeting last month.

Gredinberg walked the audience through recent changes and important information for industry estimating systems, including CCC, Mitchell, and Solera Qapter (formerly Audatex). P-pages can be found on each system’s website or via the Estimators toolbox tab on DEGweb.org.

Gredinberg said, “People in the industry often ask ‘What is CCC and what exactly is the information provided for MOTOR?'”

MOTOR Information Systems, a Hearst Company, is one of the world’s premier suppliers of automotive data, he said. CCC Intelligent Solutions Inc. is a leading Software as a Service (Saas) platform.

“CCC exclusively leverages MOTOR automotive data in its estimating solutions available to collision repairers, insurers, and independent appraisers,” Gredinberg said.

He said CCC receives the data from MOTOR.

“Labor times, for example, don’t come from CCC,” Gredinberg said. “MOTOR provides the data over to CCC.”

MOTOR has historically provided a PDF version of the Guide to Estimating (GTE), but new in 2024 the PDF version will no longer be available from MOTOR directly.

Gredinberg said he’d received a lot of questions about MOTOR’s removal of the GTE PDF options on its website. He, in return, sent an email to CCC tech support.

MOTOR responded that the estimating pages are licensed products, he said.

“They’re not going to be online anymore,” Gredinberg said. “It’s best to use a live version through the CCC platform or through the links that we shared with you.”

Any printed PDF pages someone has are likely outdated, he said.

“You are using some information that is not relevant anymore,” Gredinberg said. “For us that are repair planners, we need to use current and live updated information.”

CCC updates are noted in each book section with a star (*), Gredinberg said. The updated language will appear in blue.

Recent updates to CCC include language in “Estimate Work Time Premise,” “Labor Procedures,” “Refinish Time Premise,” and “Refinish Procedures.

Under the “Work Time Premises” category, CCC defines what is included in a labor estimate for test fits. It also added estimated work times for two procedures.

Reported times include one test fit of a component and normal adjustment procedures within the range of motion permitted by the fastener(s) or component to ensure proper fit of the individual new part being replaced. (Gredinberg added that the estimate does not include work time needed to fit the component more than once.)

DEG Inquiry 35663 clarified further: “According to the Labor Premise in the MOTOR Guide To Estimating, “Reported times include normal align procedure to insure proper fit of the individual new part being replaced.” Time for test fit is factored into estimated work times for new, undamaged components. If this is related to an R&I (remove and install) operation, the same premise holds true. According to the definition of R&I, “Item is removed, set aside and later reinstalled and aligned for proper fit.”

Gredinberg said, MOTOR Estimated Work Times (EWT) do not include a second fitment (or more) of a component to the vehicle for any reason (including verification of dimensional accuracy or adjacent part alignment). If more than one component installation is required for a specific repair plan, an on-the-spot evaluation should be used for the number of fitments beyond the first one required to perform the repair.

Estimated Work Time Changes:

-

- Estimated work times, including capping and covering exposed heating and cooling system, A/C system, oil lines, fuel lines, and electrical connectors to prevent foreign contamination when necessary. (Gredinberg gave an example of connector lines to cooling proponents and radiators.)

- Estimate Work Times for a component attached with adhesives, welds, and/or rivets including removal of rivets, welds, weld nugget(s), and component removal. Prepping attachment surface and replacement components(s), drilling as required, deburring, Pyrosil, and adhesive application, electromagnetic compatibility screws (EMC) screws (if required), installing rivets and welding as necessary.

Under the “Labor Procedures” category, CCC updated what is and is not included in labor time estimates for Front Lamps, Road Wheel/Tire, and Pickup Truck Box Side Panels:

-

- Front Lamps have been updated to include ballast, circuit board, ignitor, modules, and motors. Bulb(s) were already and remain a part of the procedure. (Gredinberg said lamps have been updated as lamps become complex systems with newer technology).

- Road Wheel/Tire Remove and Replace (R&R) has been updated to include torque wheel to OE specifications. It already includes labor needed to raise and support the vehicle, remove and reinstall wheel/tire assembly, transfer/remove and replace the tire, lower vehicle, valve stem, and Tire Pressure Monitor Systems (TPMS) sensor, if attached to the valve stem.

- Pickup Truck Box Side Panels were updated to include a special notation that says some bolted-on box side panel replacement components may or may not be supplied with duplicated OEM caulk/seam sealer. This is not included in the remove and replace time and requires an on-the-spot evaluation.

Under the “Refinish Time Premise” category, CCC gives new details on determining estimates for bumper reinforcements and impact bars and updates what’s not included in refinish, wet/dry sand, denib, and or rub-out time.

-

- Bumper reinforcements and impact bars– MOTOR has determined that paint found on factory-installed impact bars and bumper reinforcements is an artifact of the factory refinish process (over-spray). Impact bars and bumper reinforcements may come from the factory refinished in various stages of completeness and quality. However, replacing the OE refinish on factory-installed impact bars and bumper reinforcements may not satisfy the paint manufacturer’s warranty requirements. See “Special Precautions, Refinish Clear Coat Application” for further information. These factors should be considered when developing the estimate after an on-the-spot evaluation. (You determine what needs to be done to complete the repair).

- Refinish, wet/dry sand, denib, and or rub-out time does not include Assembling/setting up a unique fixture/stand to hold parts for refinishing. (For example, removing a part and then putting it on a stand.)

Under the “Refinishing Procedures” category, CCC updates that flash and wait time between material applications are not included in multiple applications and refinishes. It also details how long flash time should be on specific procedures and updates refinish times for color blending.

-

- Basic color coat application is updated to say mix pre-made color with necessary solvents added as an included procedure. Flash/wait time between material applications added as not included.

- Clear coat finishes for base and clear coats are updated to say flash and wait time between material applications added as not included.

- Three-stage finishes, including base, mica, and clear coats, are updated to say flash and wait time between material applications added as not included.

- Clear coat undamaged panel is updated to say flash and wait times between material applications are not included.

- Flash process is updated with a note about not force-drying. It asks that drying be completed at 68 degrees for 15-20 minutes. An application that says two medium wet coats over Diamont or ONYX HD basecoats are needed was also added. It notes five to 15 minutes is needed between the two coats.

- Color blend adjacent panels updated estimated refinish times for color blending, saying it should defer to the judgment of an estimator or appraiser following an on-the-spot evaluation of the specific vehicle and refinish requirements in question.

- Three-stage color blend for adjacent panels is updated to say that estimated refinish times for color blending should defer to the judgment of an estimator or appraiser following an on-the-spot evaluation of the specific vehicle and refinish requirements in question. (Removed any formula regarding blend, such as the old 50% formula.)

A blend study was conducted by SCRS in August 2022 in coordination with AkzoNobel Vehicle Refinishes, Axalta Coating Systems, BASF Automotive Refinish, PPG Industries, and Sherwin-Williams Automotive Finishes. The purpose was to study the comparative difference between the time necessary to perform a full refinish on an exterior panel and the time needed to blend the same panel.

The study concluded blending took 31.59% more time on average than a full refinish based on results from refinish operations compared to 45 different parts with three colors from the five paint and coatings companies. The results starkly contrasted the 50% less time historically allocated in the three estimating systems.

In April 2023 MOTOR issued a press release announcing research it had conducted, resulting in the changes featured in the GTE update.

Gredinberg said there are no indications on Mitchell’s website that tell a user what has been updated. He highlighted some changes to Mitchell’s estimating Guide for labor.

-

- Caulking for standard Factory application was updated to say labor times shown in the Guide for bolt-on panels include the application of caulking/seam sealer. The performance of this operation is inclusive of the requirements necessary to replace the factory application of caulking/seam sealer. Necessary requirements may include, but are not limited to: Prep Work, priming for adhesion, masking, standard factory application of caulking/seam sealer, and cleanup. In some instances, Mitchell may determine that an OEM replacement part(s) is not serviced consistently by a vehicle manufacturer. In those cases, we will footnote the specific panel(s) with the labor footnote: #Does Not Include Application of Caulking and a headnote will be included in that section with a labor allowance for the performance of the task if necessary.

- A/C Evacuate and Recharge was updated to say the labor times shown in the Guide represent utilizing A/C servicing equipment in a collision repair environment that evacuates the system by applying a vacuum that must then be held by the system for a certain period of time (leak check) confirmed with electronic leak detection equipment post-refill. Diagnosing a failed leak check test is not included.

- Adhesive Emblems was updated to say the labor times shown in the Guide represent installing the emblem in the correct location by performing some combination of measuring, marking and aligning to ensure proper positioning. Time for the fabrication of a template for emblem installation per specific OEM procedure is not included.

- Accessing Repair Information was updated to say it does not include research, retrieval, review or usage cost of OEM and/or other service procedural information.

- Weld Testing was updated to say it does not include time to perform weld testing or matching. The performance of destructive weld testing.

During the same meeting, Jack Rozint, Mitchell repair sales senior vice president announced during open mic that it will update its cloud estimating tool in February to allow for flexibility in labor time calculations for refinish operations, such as blending.

When asked if the updates would include changes in the company’s guidance on blend formulas within the CEG, Rozint replied there would be no change at this time. This means Mitchell has not adjusted their guidance on blend formula.

Gredinberg said any additions or corrections for Solera/Qapter are identified in bold and italicized font. The language removed has a strikethrough.

Qapter was updated to say any fees related to OEM data subscriptions and/or OEM information access are not included in part prices or labor values within Audatex Estimating.

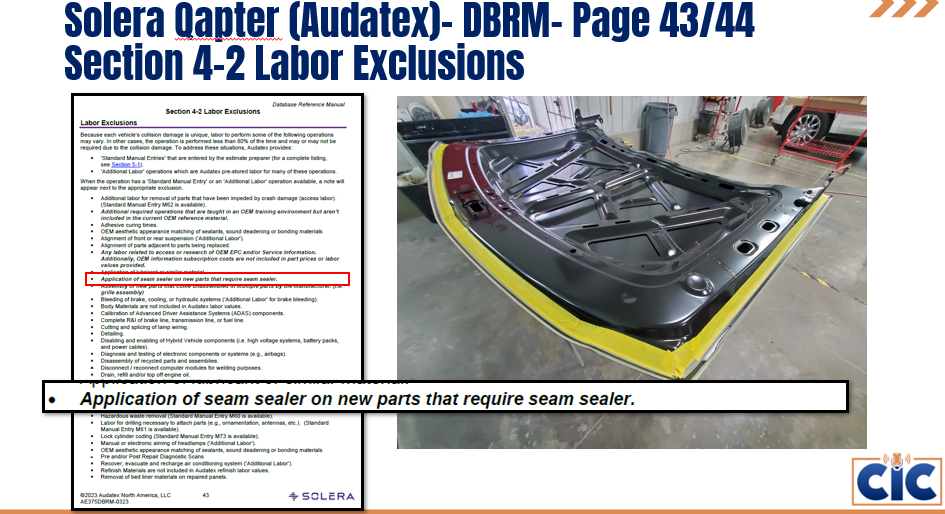

Database Reference Repair Manual (DBRM) Labor Exclusions were updated with new procedures not included in estimates.

-

- Additional required operations that are taught in an OEM training environment but aren’t included in the current OEM reference material.

- Any labor related to access or research of OEM engineering, procurement, and construction (EPC) and service information. Additionally, OEM information subscription costs are not included in part prices or labor values provided.

- Application of seam sealer on new parts that require seam sealer.

- Assembly of new parts that come unassembled in multiple parts by the manufacturer (i.e. grille assembly)

- Setup of rivet equipment, riveting materials, and/or test riveting

DBRM Refinish Guidelines addressing blending were updated similarly to MOTOR.

Under Section 4-4 “Refinish Guidelines,” Solera removed its previous blend formula — “50% of Audatex estimate refinish labor after overlap consideration, including two-stage or three-stage allowances, if applicable for the panel to be blended” — and replaced it with guidance that “Audatex Estimating does not provide a standard labor allowance for blended panels as this requires the estimate preparers judgement, expertise and consideration of unique requirements for each repair.”

Product Management Senior Director David Davoodi told Repairer Driven News last month that Solera was already aware of the concerns the Society of Collision Repair Specialists (SCRS) and other repairers had for months, if not years, prior to the release of the results of the association’s blend study results in November 2022.

Examples of feedback he cited were paint and refinish operations becoming more complex because of matte finishes, four-stage refinishing, and very deep reds, which require a lot more labor time.

IMAGES

Feature image is of Danny Gredinberg, Database Enhancement Gateway (DEG) administrator, presenting at the Collision Industry Conference Jan. 17 meeting. (Teresa Moss/RDN)

Slides in the story are from Danny Gredinberg’s presentation at the Jan. 17 Collision Industry Conference meeting.