On Target: New Mach-E procedures, Ford/I-CAR courses

By onCollision Repair | Repair Operations

Ford’s recent issue of On Target newsletter shares some new and important repair procedures on the Mach-E, as well as four repair courses for 2023 and 2024 Ford and Lincoln vehicles.

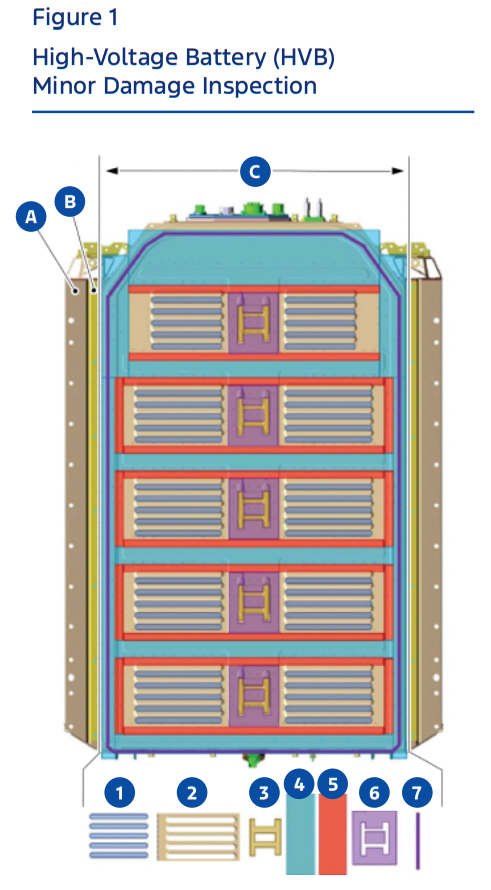

The Mach-E procedures have to do with a newly expanded sub-section in the official Ford Workshop Manual (WSM) that focuses on inspection and repair of minor high-voltage battery damage from curb strikes or driving over road hazards.

As always, On Target notes that the information is just hitting the highlights. In-depth information can be found in the Ford WSM at FordServiceInfo.com.

First, to prevent the risk of high-voltage shock, Ford says to always precisely follow all warnings and service instructions, including how to de-power the system.

“The high-voltage systems use high-voltage cables to connect their components and modules. The high-voltage cables and wiring are identified by orange harness tape or orange wire coverings. All high-voltage components are marked with high-voltage warning labels

displaying a high-voltage warning symbol. Failure to follow these instructions may result in serious personal injury or death.”

This previous demonstration by I-CAR provides a visual of a high-voltage system:

I-CAR Technical Programs and Services Director Dirk Fuchs demonstrated an EV low voltage system cart during a July 2022 Collision Industry Conference (CIC) meeting. The cart replicates the high voltage systems that are in EVs and is used in their training courses.

When an EV comes into a collision repair shop, Fuchs cautioned that to avoid injury, repairers should look with their eyes and not their hands until a high voltage expert says it’s safe to touch. He also recommended wearing gloves as standard PPE for first examining a damaged EV. Another safety measure is to ensure there is at least 16 feet of space around the vehicle, he said.

Specific to new repair steps released for the Mach-E, the second step after de-powering the system is to check for diagnostic trouble codes (DTCs) and follow diagnostic procedures to address them. Then, with the vehicle in neutral, position it on a hoist and check the bottom of the high-voltage battery. The diagram below shows how to identify the repair required, depending on the zone location of the damage.

Ford plans to include more details on the procedure in future volumes of On Target.

Four new repair courses are also available from Ford and I-CAR, which the latest On Target issue provides a brief overview of:

Other important information regarding repair procedure updates covered in the latest issue is the types of steel that make up the Mach-E body-side inner panels, front panels, aprons, and side members.

Diagrams and charts are provided in the On Target issue and “Section 501-26: Body Repairs – Vehicle Specific Information and Tolerance Checks, Description and Operation” of the WSM.

On Target plans to include more construction details on the Mach-E in future volumes, including some of the special tools needed for service, as found on Ford’s Rotunda website.

Technical information on how vehicles with BlueCruise operate intelligent adaptive cruise control operation and lane centering is also briefly covered in the issue.

All editions of On Target can be found at fordcrashparts.com/on-target.

On April 4, Ford shared in a news release that it continues to invest in a broad set of electric vehicle (EV) programs while working to build a full EV lineup.

The initiatives support the development of a differentiated and profitably growing EV business over time while Ford serves customers with the right mix of gas, hybrid, and electric vehicles based on demand, the release states.

By the end of the decade, Ford plans to offer hybrid powertrains across its entire Ford Blue lineup in North America. In Q1 2024, Ford’s EV sales increased by 86% and hybrid sales by 42% compared to Q1 2023.

Ford’s construction of the BlueOval City campus in __, which includes the Tennessee Electric Vehicle Center assembly plant, is progressing on track, according to the release. The installation of paint shop, vehicle assembly, and nearly 4,000 tons of stamping equipment is underway. The stamping equipment will produce the sheet metal stampings for Ford’s next electric truck, the release states.

Images

Featured image: Mustang Mach-E Rally (Provided by Ford)

Diagram and key provided by Ford On Target

I-CAR’s Dirk Fuchs demos an EV battery system cart during July’s CIC special session.