Honda OK’s 2 new higher-strength welding wires for collision repair

By onAnnouncements | Market Trends | Repair Operations | Technology

Honda announced this month it had approved two new welding wires for repairs of higher-strength steel on its vehicles.

The 0.8 mm (0.030-inch) Titan Technology EQ-5029X96, supplied by Equip Automotive, and Washington Alloy Eagle-Arc 980X — which Honda says should be on sale “at most welding supply locations” — have been deemed acceptable for welds of metals 590 megapascals or more.

They join the Bosch DS980J wire, which has been discontinued but still can be used if you have some, and its replacement 0.8 mm Bohler Union X96 wire in the portfolio deemed acceptable by Honda for higher-strength steel work.

Only Pro Spot and the Honda Tool and Equipment Program (Honda Snap-on) sell Bohler X96, Honda said.

Honda warned repairers in 2016 to be on guard for knockoff versions of the Bosch and Bohler wire. Shops will want to continue to stick to authorized supply channels of both these and the newly approved wires rather than risk their customer and reputation on an unproven or gray-market spool.

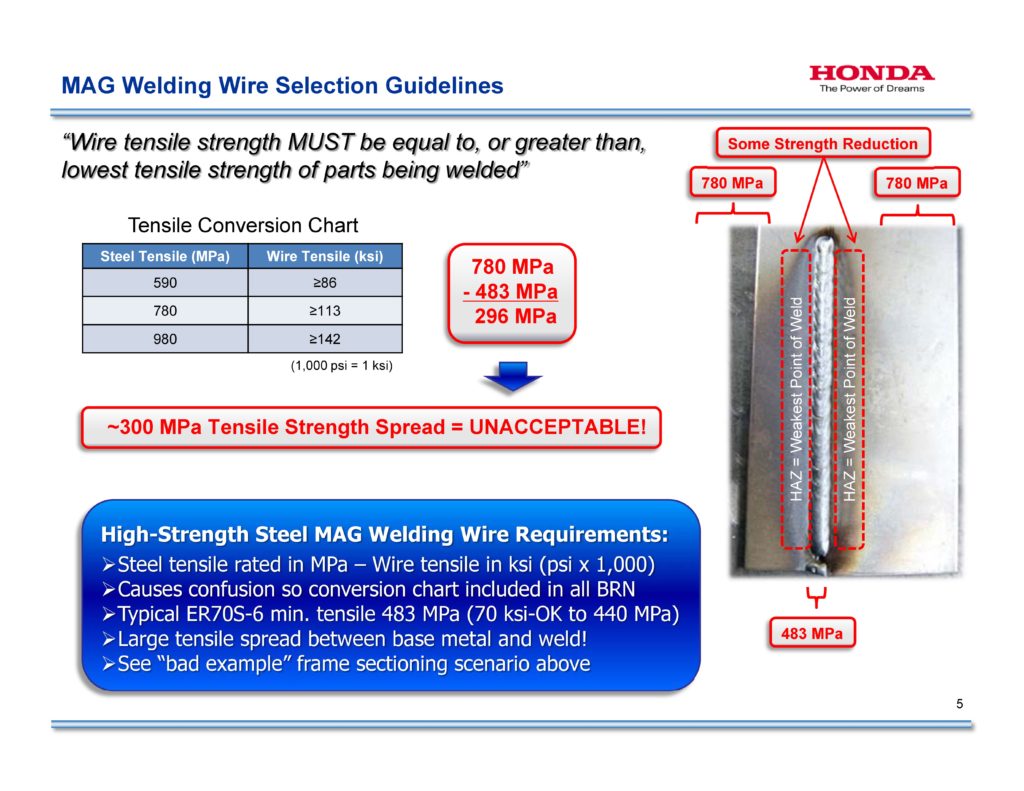

You need the stronger wire to avoid a situation where the weld is weaker than the metal it’s joining. Your typical ER70S-6 welding wire is 70 ksi (70,000 pounds per square-inch), according to Honda. This only works out to about 482.63 MPa of tensile strength — stronger than 440 MPa steel but weaker than a 590 MPa piece of the metal.

Honda in 2016 gave the example of welding two pieces of 780 MPa steel. ER70S-6 wire nearly 300 MPa weaker could cause the weld itself to fail. Using higher-strength wire means the weld holds and the heat-affected zone of the substrate fails instead — the outcome Honda expects during a subsequent collision.

Honda only permits MAG plug and butt welding in general on steels up to 780 MPa, but “butt welds on 780 MPa steel must be done as quickly as possible, while maintaining adequate penetration” to prevent an unacceptable heat-affected zone, the OEM wrote in a 2017 Body Repair News.

At 980 MPa, only MAG plug welding is acceptable, Honda wrote in the Body Repair News. The OEM said it occasionally will in repair procedures allow MAG plug welding on 1,500 MPa steels — but implied these are exceptions rather than the rule and aren’t permitted unless explicitly mentioned.

In that vein, follow the specific OEM repair procedures for the Honda or Acura before you — the Body Repair News documents aren’t intended to be substitutes for the actual manuals.

More information:

“Additional High-Strength-Steel Welding Wire Approved”

Honda Body Repair News, June 2019

“Body Repair Manual Welding & Sectioning Guideline Revisions”

Honda Body Repair News, June 2019

Honda official OEM repair procedures website

Honda in December 2016 explained why auto body shops needed to weld higher-strength steels with equally strong wire. (Provided by Honda via VeriFacts)