Consultant: Industry needs to come to consensus on color verification definitions, operations

By onBusiness Practices | Collision Repair

Collision Industry Business Consultant Charlie Whitaker said recently that if the collision repair industry can come to a consensus on the color verification process in refinishing, there would be better outcomes from service providers and billpayers.

The result would be SOPs, training videos, and better overall education of service providers to effectively communicate the need for certain steps of the process to billpayers.

“This is something we do to every single car that comes through the shop,” Whitaker said of color verification. “I feel like there’s a huge opportunity here.”

While there are a lot of variations in the process from manufacturer to manufacturer and system to system, it’s always a complex process, he said.

“Think about the steps you actually physically take and how it aligns with your actual repair plan. …when I looked at all the different estimates or repair plans that come across the desk and what different writers are writing and seeing, I would see all sorts of different hodgepodge of tint, check for color, spray out, secondary colors. It was just across the board and depending on who you talk to, there was a different meaning as to what it may include, what it did not include.”

Whitaker said there are several reasons for variations, including:

-

- Lack of knowledge: Service providers may not know what technicians do to check and verify accurate colors or have a complete understanding of the software they use.

- Inaccurate information: pin codes could be wrong or there could be incomplete vehicle inspections.

- Poor communication with technicians and billpayers: “Did they actually have a conversation with the painter to understand all the different colors and/or steps involved? I believe all these things create the variations in that process,” Whitaker said. “Poor communication with the technicians [is] ultimately poor communication with the billpayer.”

- Time pressure: Just getting the job done to move on to the next task. The service writer may be under pressure to complete estimates quickly, which could lead to overlooking important steps or details.

Whitaker recommends technicians write down the steps they take during their color verification process and gave examples of how to do so.

-

- Gather information about the vehicle make, model, and paint code that is found on the car.

- Go to the paint manufacturer database to see how many variants they may have, select the appropriate chip or camera parameters to verify the variants, consider appropriate lighting sources, prep the blend panels, and check the adjacent panel’s color to know what will be blended into.

- Mix the colors, and in many cases, mix a colored sealer plus a top coat that clears.

- Set up and test spray equipment including a test card. Apply the paint as required by a TDS, ensuring that the paint is applied evenly and smoothly, and all appropriate layers are considered.

- Allow drying time then check your match to see if it’s good. If not, go through all the steps again and again until it’s right.

- Final inspection: Inspect the repaired area one last time to ensure that the color match is perfect and that the repair is complete.

“There’s actually a ton of different steps in the color verification process,” Whitaker said. “My question is, do you actually capture that in a simple line that might say ‘tint color,’ whatever it might be that was on your repair plan? And then you think about all the variations that you see come across your desk; is it accurate?”

Secondary color verification follows the same steps Whitaker outlined above. If there are underfoot colors, including under the hood or backside of panels, the trim, wheels, jambs, or multi-layer coatings and tinted sealers the process will be repeated multiple times during repairs.

“It’s not a one-size-fits-all,” Whitaker said. “[I]f we all set a test for our card and we all knew what that was and agreed upon it, then we would have a different outcome. …I feel that is a state that would be great to get to across the industry because it’s great to have these tools. But also, at the end of the day, we’re running a business to get paid and it would be nice to get paid for our time. If you look at CCC’s P-pages… they do list mixed paint in the included section. However, again, subjective to def to understanding.”

Information providers (IPs), he added, follow ambiguous language, lack alignment with each other and the verification process, and lack operational definitions for words and procedures.

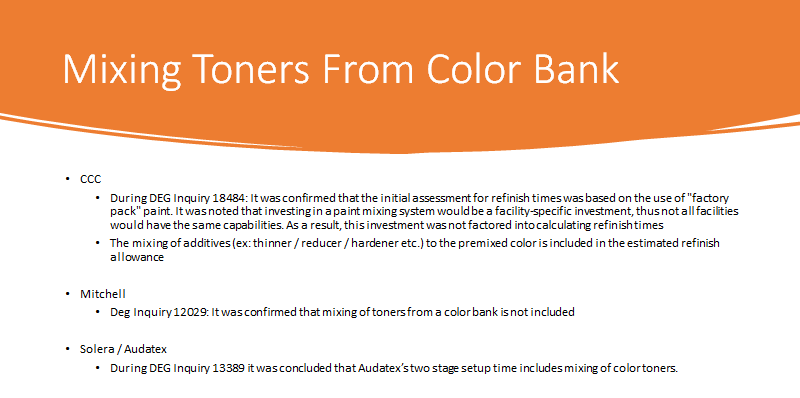

For example, CCC’s not-included operations are test spray-out panel, tinting primer-sealer, and tinting to achieve color match — to name a few, while an included operation is mixing paint color with necessary solvents. Comparitively, Mitchell International considers mixing materials an included operation and color match or tinting not-included. Audatex considers the initial tint, spray test panel, let down, and compare to the vehicle.

Whitaker shared the following Database Enhancement Gateway (DEG) inquiries that helped shed some light on included and not-included color verification procedures:

“Terminology, our words, do matter,” Whitaker said. “I have found any time you can align it with a P-page or documentation, it supports our argument better. But the challenge today is that there is no alignment within the industry between the information providers and then that of the coatings companies; everybody has just done their own thing.”

Society of Collision Repair Specialists (SCRS) Executive Director Aaron Schulenburg said the issues Whitaker described were brought up by SCRS members.

“This highlights the complexity of the refinish process that we go through and that complexity only changes. There’s a lack of understanding of what it takes for a professional collision repairer to go through these tasks. And so I appreciate the insight and I think good questions to challenge the industry with where we go from here.”

Images

Featured image: Collision Industry Business Consultant Chris Whitaker speaks during SCRS’ April 2023 open board meeting. (Lurah Lowery/Repairer Driven News)

More information

CCC, MOTOR to roll out ‘on-the-spot’ blending options beginning in October