Mitchell: Toyota integration not substitute for researching OEM procedures

By onBusiness Practices | Education | Insurance | Repair Operations | Technology

Mitchell confirmed Sunday that its integration of Toyota repair procedures into the estimating process wasn’t meant to replace auto body shops using the OEM’s actual repair procedures.

“TRRP is designed to quickly create an estimate based mainly on panel replacement – on the spot evaluation and adjustment by the repair planner is always recommended to finalize the estimate and repair blueprint,” Mitchell wrote.

The question recently arose during an interaction between an insurer and regional Montana MSO Big Sky Collision, and Mitchell’s response should help clear up any other confusion in the marketplace.

Body shop owner Matthew McDonnell on Friday recounted spending 15 hours pulling repair procedures and building an estimate to repair a vehicle, only to have it total. He billed for his time, noting Friday that he wouldn’t just accept a mere two hours for teardown and eat other labor.

That effort might surprise some customers and insurers — and even some shops — but as Collision Hub’s “Repair University Live” demonstrated last year, properly blueprinting a repair can really take a shop down a rabbit hole of research and work. (McDonnell noted that shops which train with his facility on estimating have lamented, “This is overwhelming.'”)

The insurer involved had asked McDonnell why his shop had taken so much time given Mitchell’s predictive estimating featuring Toyota repair procedures.

McDonnell recalled that he at first felt stupid at having forgotten Mitchell’s “Toyota Recommended Repair Procedures” feature, and he checked his estimating service to see if he could have indeed simply built the sheet that way.

However, he said this only yielded three of the procedures of the 15 he’d found, and what existed was dated, he said.

“She paid the full bill,” he said of the insurer representative.

Mitchell explained Sunday that the “Toyota Recommended Repair Procedures” integration was never meant to replace accessing the full repair procedure library on Toyota’s official Technical Information System (TIS) or the licensed version on Mitchell TechAdvisor.

“I would add that we recommend that repairers have access to more complete OEM repair data in addition to TRRP – either with a subscription to a full OEM repair database (such as TechAdvisor) or with a subscription to TIS obtained directly from Toyota (which has the benefit of no delay in data updates),” Mitchell repair sales and service Vice President Jack Rozint wrote in an email.

Rozint provided a copy of a response he said Mitchell had released earlier:

1. The TRRP (Toyota Recommended Repair Procedures) solution was never meant to eliminate the need to access and use TIS.

2. TRRP is designed to quickly create an estimate based mainly on panel replacement – on the spot evaluation and adjustment by the repair planner is always recommended to finalize the estimate and repair blueprint

3. TRRP shows procedures mapped to the line level – however many items in TIS do not map directly to repair lines – therefore the need for TIS access to see all position statements, CRIB bulletins, etc.

4. We currently receive updates from Toyota on a quarterly basis and immediately push them out on our next data update – therefore TIS and TRRP are not always 100% in sync

So there you go. Mitchell’s TRRP can help repairers be more in compliance with OEM procedures and get started, but shops will still need to do their own homework to fully plan the repair.

More information:

Toyota Technical Information System OEM repair procedures

Mitchell webpage on Toyota Recommended Repair Procedures feature

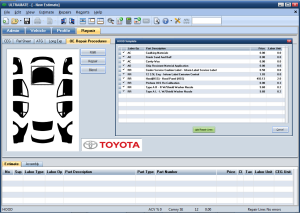

Featured image: Mitchell in 2015 integrated some of Toyota’s Recommended Repair Procedures within Mitchell Estimating, allowing users of the desktop service to obtain a list of some labor for a particular repair. (Provided by Mitchell)